Douglas Parkes, a pioneer of modern tunnelling technology and leading figure of the British Tunnelling Society, died after a short illness on the 4th June, aged 94 years.

His long career in civil engineering started in 1954 when he joined the heavy civil engineering contractors, Charles Brand & Son Ltd as an indentured pupil of James Rennie after graduating from Cambridge University.

For the next 26 years he worked in various positions with contractors. His first site work was on the foundations of Portishead B Power Station, followed by six years as a tunnel engineer on the twin Clyde Road Tunnels in Glasgow, driven in silt and rock in high pressure compressed air. He was an engineer onsite for the duration of the contract.

For many years the Corporation of Glasgow recognised the need for a crossing of the River Clyde away from the centre of the city. Preliminary planning was started soon after the end of World War Two and a site was selected approximately 5km west of the city centre.

A major motorway system was being planned that would join with the tunnels. Because of limited space at the approaches that linked to the motorways, these would have the steepest overall gradient of any highway tunnel in the world at that time, which later led to problems with controlling the tunnel shields while building the up-grade sections.

After various site investigations and planning processes were complete, tendering opened in July 1956 and the contract was awarded in June 1957 to Charles Brand & Son Ltd, with whom Parkes had been serving as a graduate engineer for three years.

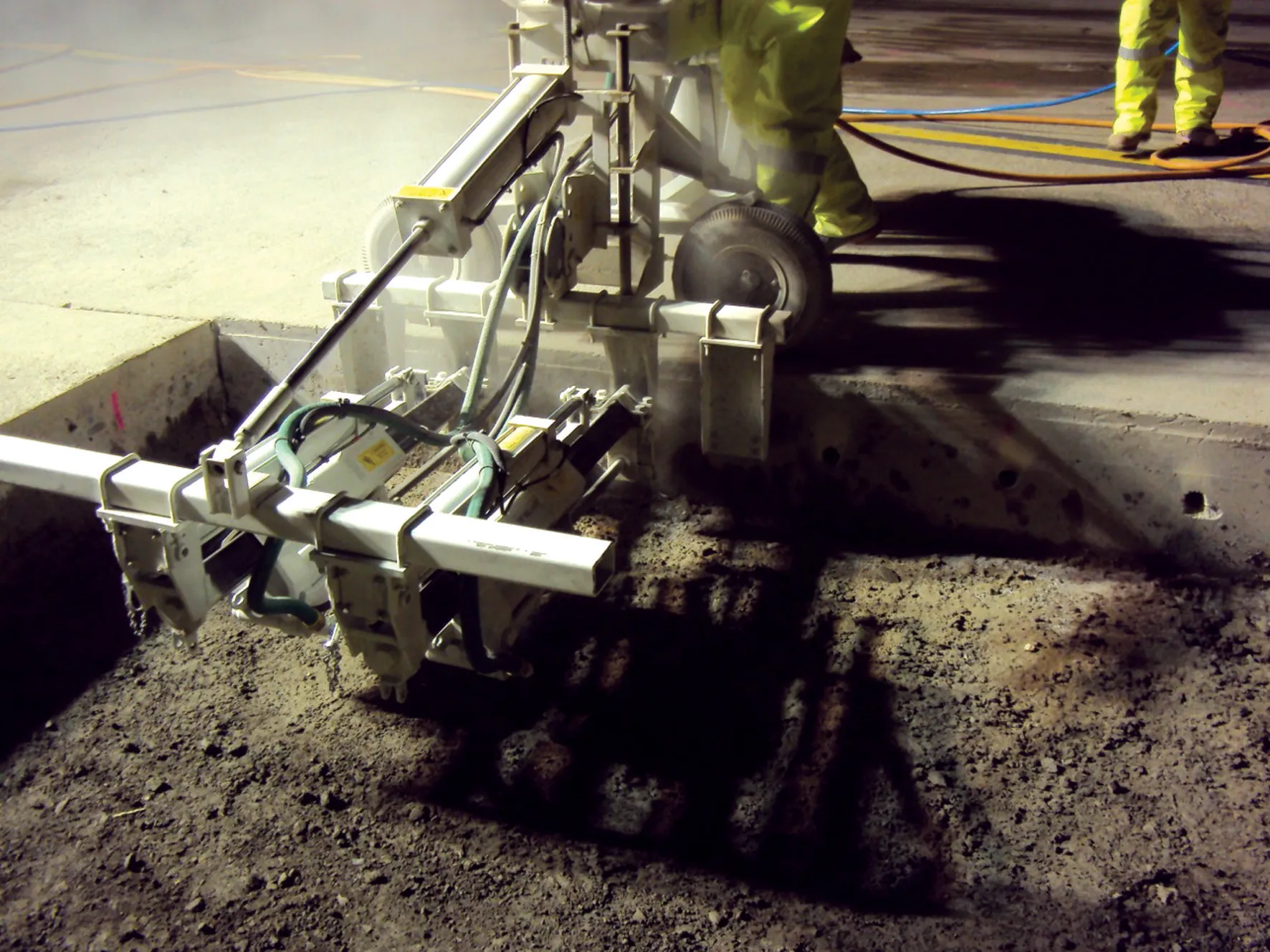

The cast iron lined tunnels are each some 750m-long and approximately 9m in diameter. These lie in beds of alluvial material overlaying shale and were driven by hand, the majority under the protection of a tunnelling shield, as tunnel boring machines of that diameter had not yet been developed at the time.

The water bearing nature of the ground meant that the tunnels were driven in compressed air, at pressures reaching nearly 2 bar, requiring lengthy decompression periods at the end of a work shift. Amongst other problems a major “blow” occurred when the first tunnel reached the recess for the western end of the vehicular ferry across the Clyde. Compressed air escaped past a timber pile of the recess, allowing the pressure in the tunnel to drop and the tunnel to flood with water and silt to a depth approaching 2m. A cavity of around 230m3 formed at the surface, requiring immediate filling as work continued below to make the tunnel safe.

On completion of that contract Parkes moved to a position as a section engineer on a length of the London Underground Victoria line, his first experience of working with tunnelling machines.

In 1969 Parkes left Brands and joined C V Buchan Ltd as their contract agent on a sewer tunnel contract in Telford New Town. After that contract he became contracts manager for several tunnel contracts in the Midlands and North West.

In 1971 Buchan became a division of Leonard Fairclough Ltd and by this time Parkes had been appointed a director of the division. He had responsibility for the 2km of tunnels on the Liverpool Link railway driven in sandstone and lined in a combination of segmental lining and in-situ concrete and in 1974 the twin cast iron lined running tunnels and all associated works of the Forth Banks to Jesmond section of the Newcastle metro. In 1977 he became managing director of the Division.

In 1980 he joined other ex-colleagues from Charles Brand in the formation of an engineering management consultancy, Bush & Rennie. A group of chartered engineers, they provided both planning and advisory services to a range of clients.

The Geotechnics branch of Arup was at that time seeking to broaden its horizons into tunnelling and had won a contract for the design of a baggage transfer system at Heathrow airport which included a tunnel section between Terminals 1 & 4. Parkes provided the tunnelling input into the design. This had a sequel, when in 1994 there was a major collapse in the new tunnel for the Heathrow Express rail link while under construction and BAA’s insurers appointed Arup to investigate and Parkes became involved.

His final task at the age of 81 before a well-deserved retirement was advising on the Powerlines Undergrounding project on the site of the 2012 London Olympics. Parkes was a founding member of The British Tunnelling Society, its chair for two spells, and an author of papers presented at its evening meetings, which he attended regularly.

He served on the Committee for the Redrafting of BS 6164 (Health and Safety in Tunnelling in the Construction Industry) Code of Practice as well as on the editorial committee for Tunnels and Tunnelling International.

Parkes was a thorough and methodical engineer who put much thought into all that he said and did. Always a gentleman, he understood the dictum that loyalty must flow in two directions and treated his superiors and staff with an equal degree of respect. He is survived by his daughter, Lucy, her husband, Chris and their two sons, Marcus and Guy.