Doosan says its two new large Stage IIIB compliant crawler excavators in the 50tonne class offer the strength and productivity needed for heavy duty work such as large-scale earthmoving, moving rock, and secondary breaking projects found on quarrying and mining, highway, aggregate, demolition, and other construction projects. The 49 tonne DX490LC-3 and 52 tonne DX530LC-3 are said to have excellent fuel efficiency, while representing an excellent return on investment for civil engineering companies, major co

January 6, 2017

Read time: 2 mins

The 49 tonne DX490LC-3 and 52 tonne DX530LC-3 are said to have excellent fuel efficiency, while representing an excellent return on investment for civil engineering companies, major contractors, quarries, opencast mines and other large excavator customers.

The DX490LC-3 model is said by Doosan to have extra reach and stability which, combined with its strength, allow it to accomplish long cycles and heavy pulling work with ease. The wider undercarriage on the DX530LC-3 model is said to produce exceptional stability and unmatched lifting capabilities.

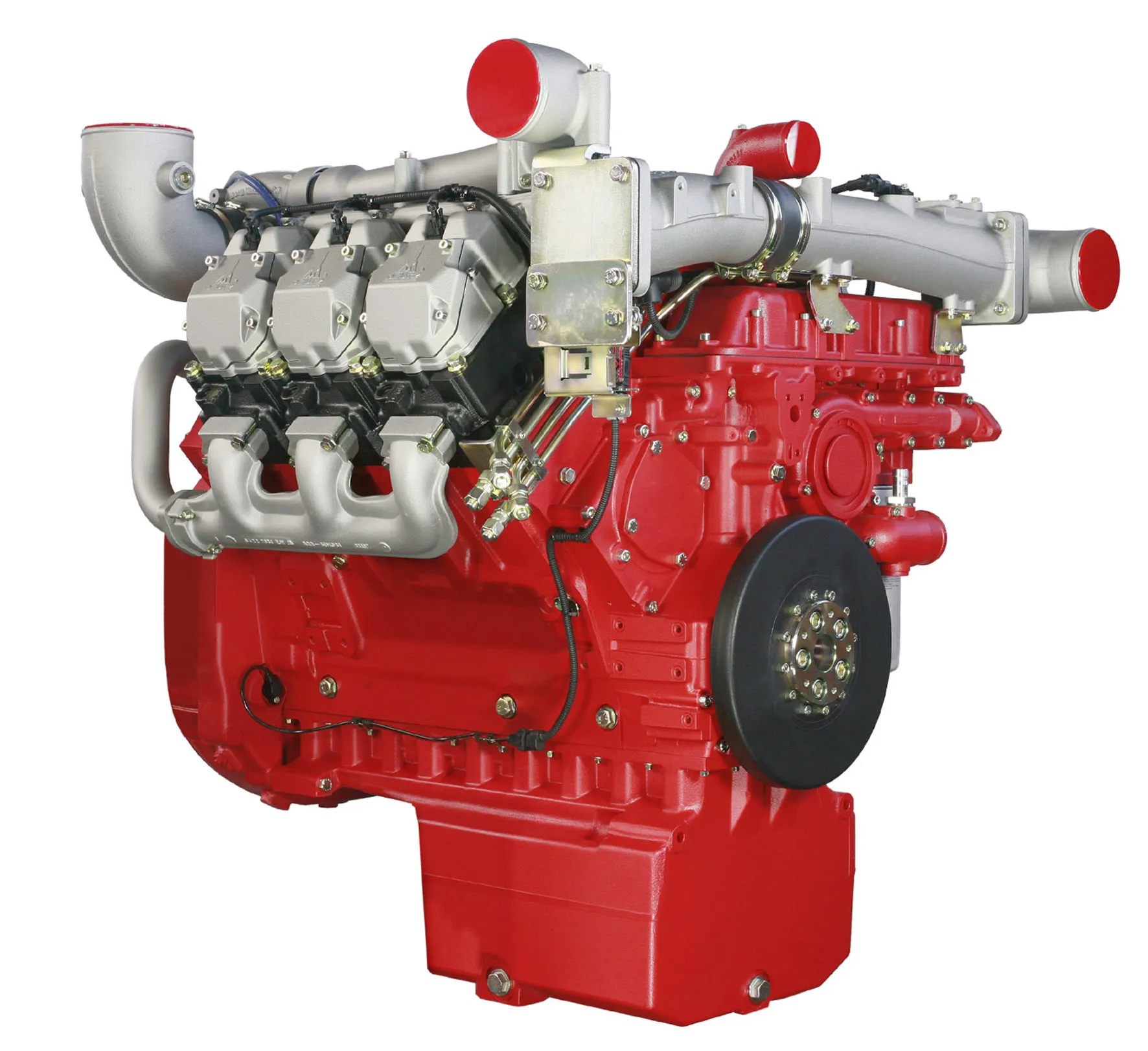

To power the new excavators, Doosan has chosen the

New hydraulic pumps and valves increase digging forces by 3-6 % which, Doosan claims, makes both excavator models the best in their class. In the DX490LC-3 model, the lifting capacities at ground level have increased by 5.5% and by up to 9% in the DX530LC-3 excavator. New travel and swing components are said to contribute to an increase in drawbar pull by 15% on both models to 38.8tonnes, offering the highest traction in their class. Swing torque in both models has increased by 23% to 15,880kg.m, and there is a 10% increase in the maximum travel speed to 5.8km/h.

Stand: F6.612/3

%$Linker: