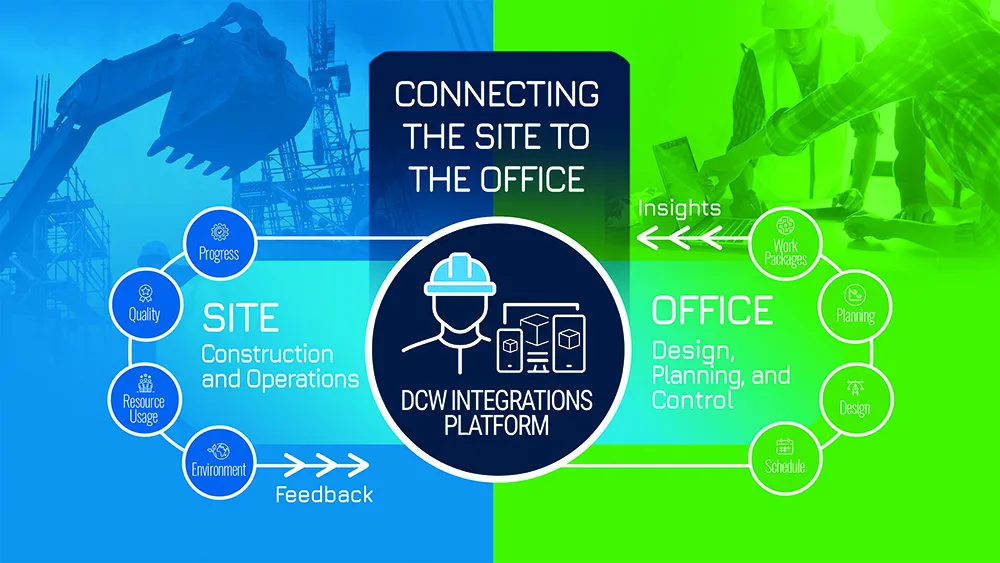

Digital Construction Works (DCW), a joint venture formed in October 2019 between Bentley Systems and Topcon Positioning Group, has developed “a fully-integrated highway design and construction workflow where all of the project data is combined within the platform,” says the company’s chief executive officer Jason Hallett. Everything is intelligently put together in “a place where it can be analysed and visualised into valuable project insights.”

DCW is focused on digital integration and automation services across the whole construction sector, and the new workflow tool will allow contractors to integrate the schedule and the tasks of machines on site. “If you could do that automatically, you don’t have to do double entry,” says Hallett. “You’re not wasting a whole bunch of time. You can communicate even with subcontractors doing that work in a more efficient and automated way. So that’s one thing we’re really focused on.

“And, of course, we’re focused on round-tripping the data back from that system, as well. We want to do it in a way that, for example, allows the subcontractor working for the GC to review and then approve the information they want to push back. And we do it all digitally.”

The idea “came from one of our shareholders, Bentley,” says Hallett. The driving force was “the integration of Bentley’s OpenRoads Designer for design, SYNCHRO 4D, which is their planning tool, with Topcon’s MAGNET mass haul and Sitelink3D product. Topcon is also one of our shareholders.”

Jason Hallett has been CEO of DCW since January 2022 after holding the position of Chief Operating Officer since the company’s inception. Prior to DCW, Jason served as Vice President of Global Software Business Development and Digital Construction at Topcon Positioning Systems.

If you would like to read more about DCW and see our full interview with Jason, please go to: https://www.worldhighways.com/feature/conquer-technology-interoperability-gaps-dcws-productivity-focused-and-digitally-connected

Or, if you would like to see Jason’s interview in a video format, please go to: https://www.worldhighways.com/video/digital-construction-works-roundtable-interview

The feature fist appeared in the 2022 edition of Global Report: https://digital.worldhighways.com/2022/globalreport/html5/?pn=1