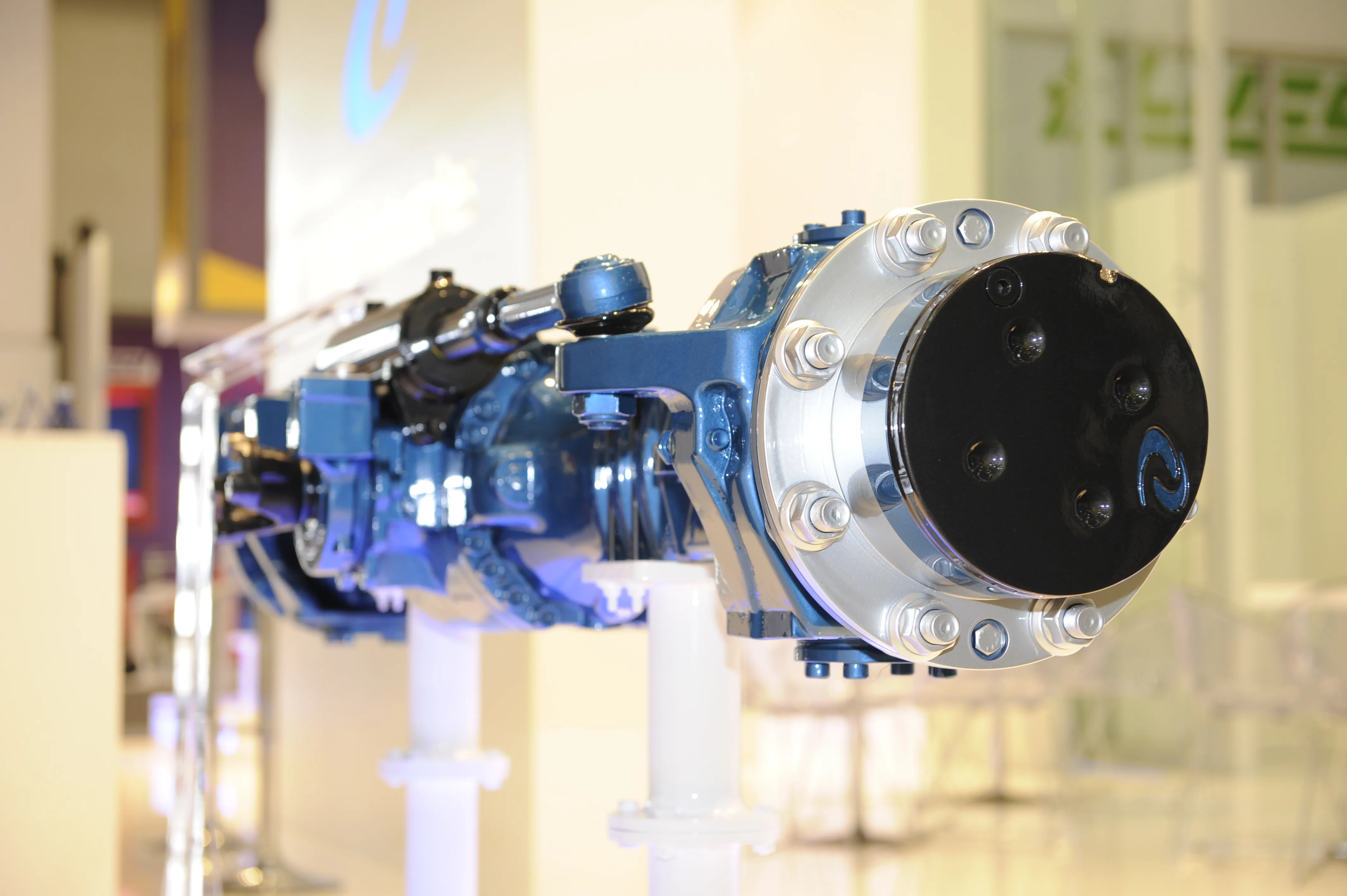

Terex has introduced the production version of its Twin Drive TC16 mini excavator.

Equipped with both a 13kW diesel engine and an 11kW electric motor, the 1.9tonne machine can be used in confined spaces with zero exhaust emissions. A 15m cable reel is installed behind the cab, allowing the machine to travel under electric power.

January 6, 2017

Read time: 1 min

RSS1222 Terex has introduced the production version of its Twin Drive TC16 mini excavator.

Equipped with both a 13kW diesel engine and an 11kW electric motor, the 1.9tonne machine can be used in confined spaces with zero exhaust emissions. A 15m cable reel is installed behind the cab, allowing the machine to travel under electric power.

Both the diesel engine and the electric motor drive the same hydraulic pump, providing equal performance and productivity whichever power source is in operation. The machine has a slightly longer engine canopy to cover the dual power source, yet retains compact slewing dimensions.

A selector switch in the cab allows the operator to choose between the engine or the electric motor, and there are separate hour meters for the two power sources.

View more stories

View more videos

Equipped with both a 13kW diesel engine and an 11kW electric motor, the 1.9tonne machine can be used in confined spaces with zero exhaust emissions. A 15m cable reel is installed behind the cab, allowing the machine to travel under electric power.

Both the diesel engine and the electric motor drive the same hydraulic pump, providing equal performance and productivity whichever power source is in operation. The machine has a slightly longer engine canopy to cover the dual power source, yet retains compact slewing dimensions.

A selector switch in the cab allows the operator to choose between the engine or the electric motor, and there are separate hour meters for the two power sources.

Outside: E5 Stand: C002

RSSView more stories

View more videos