The EU Commission is giving its approval for the joint venture between Bosch, DEUTZ, and Eberspächer. This partnership is now commencing on an operational basis start as the Bosch Emission Systems joint venture. The agreement is for a complete diesel exhaust-gas after-treatment system for non-road machinery. The package is offered on the basis of a modular system and a range of solutions is available to satisfy future emission regulations.

May 30, 2012

Read time: 2 mins

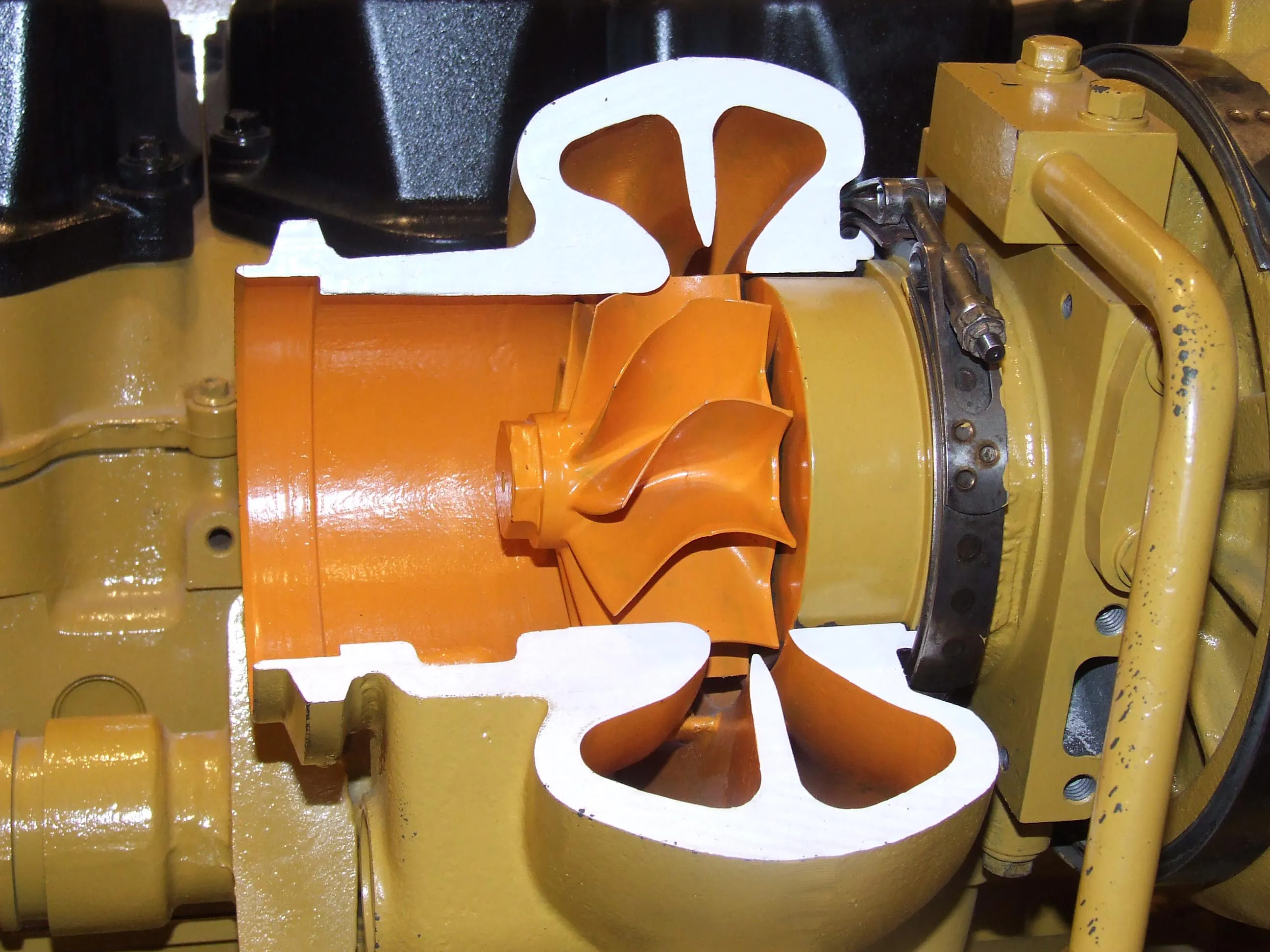

The 3287 EU Commission is giving its approval for the joint venture between 3405 Bosch, 201 Deutz, and 3435 Eberspächer. This partnership is now commencing on an operational basis start as the Bosch Emission Systems joint venture. The agreement is for a complete diesel exhaust-gas after-treatment system for non-road machinery. The package is offered on the basis of a modular system and a range of solutions is available to satisfy future emission regulations. The initial agreement was made between the partners, Robert Bosch, DEUTZ and Eberspächer on December 9th, 2009. The companies announced their intention of cooperating to reduce exhaust emissions in construction machinery but the approval of the EU Commission for this partnership has now been granted. Based in Stuttgart, Bosch Emission Systems will offer the core exhaust-gas after-treatment skills and experience of the three companies involved, and, on the basis of a modular system, will offer complete systems solutions for construction machinery as well as commercial vehicles. These complete systems include electronic control and, if required, also optimised burner technology for the regeneration of diesel particulate filters. The portfolio is tailored to mobile and stationary machinery, although commercial vehicles such as trucks and buses are a further area of use. Series production is planned for the third quarter of this year at Neunkirchen in Germany.