Driveline specialist Dana is launching the Spicer Rui Ma brand of transmissions and axles that are manufactured in China for the local market. This range complements Dana’s Spicer brand of sophisticated drivetrains and is being marketed in China as line-up with the features, performance, dependability, and the pricing structure preferred by many Chinese OEM manufacturers supplying local markets. The range has been developed at Dana’s manufacturing facility in Wuxi, Jiangsu Provence, China. The Spicer Rui Ma

November 28, 2012

Read time: 2 mins

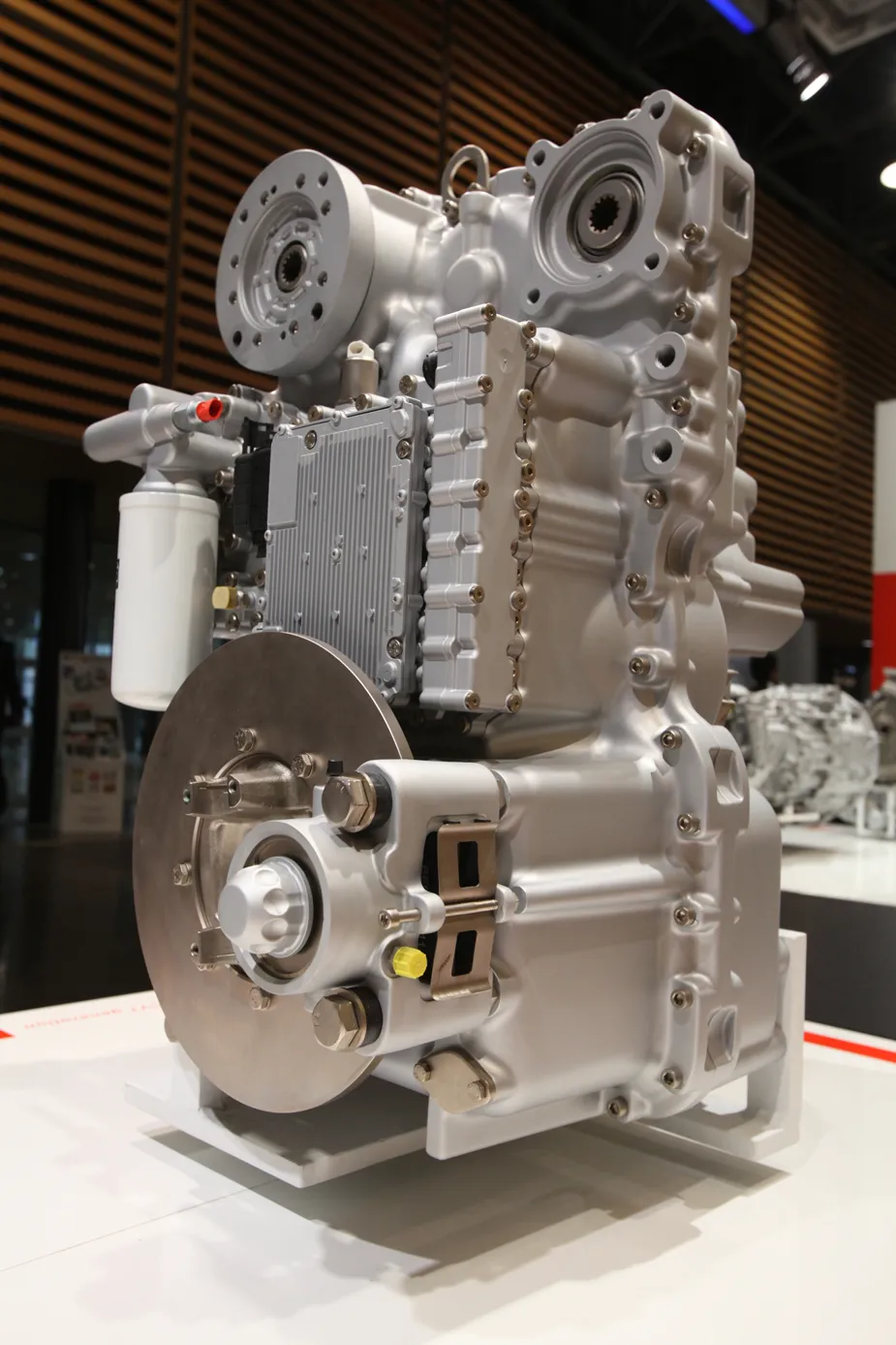

Driveline specialist 2254 Dana is launching the Spicer Rui Ma brand of transmissions and axles that are manufactured in China for the local market. This range complements Dana’s Spicer brand of sophisticated drivetrains and is being marketed in China as line-up with the features, performance, dependability, and the pricing structure preferred by many Chinese OEM manufacturers supplying local markets.

The range has been developed at Dana’s manufacturing facility in Wuxi, Jiangsu Provence, China. The Spicer Rui Ma transmissions and axles are engineered to perform throughout the life of a vehicle, but without some of the sophisticated electronics seen on the Spicer range. The units being introduced first to Chinese OEMs include the Spicer TZL16 RM powershift transmission for ZL50 wheeled loaders, the T08 RM transmission and the T39 RM tridem drive axle for five- and six-axle chassis concrete pump trucks. The company will introduce additional Spicer Rui Ma transmissions and axles in coming months.

In mid-2012 Dana announced the opening of a new aftermarket distribution centre in Wuxi and early in 2013, the firm will open a 12,000m2 technical centre in Wuxi also that will carry out advanced product and applications engineering through research, design, development, and testing of drivetrain products.

The range has been developed at Dana’s manufacturing facility in Wuxi, Jiangsu Provence, China. The Spicer Rui Ma transmissions and axles are engineered to perform throughout the life of a vehicle, but without some of the sophisticated electronics seen on the Spicer range. The units being introduced first to Chinese OEMs include the Spicer TZL16 RM powershift transmission for ZL50 wheeled loaders, the T08 RM transmission and the T39 RM tridem drive axle for five- and six-axle chassis concrete pump trucks. The company will introduce additional Spicer Rui Ma transmissions and axles in coming months.

In mid-2012 Dana announced the opening of a new aftermarket distribution centre in Wuxi and early in 2013, the firm will open a 12,000m2 technical centre in Wuxi also that will carry out advanced product and applications engineering through research, design, development, and testing of drivetrain products.

%$Linker: