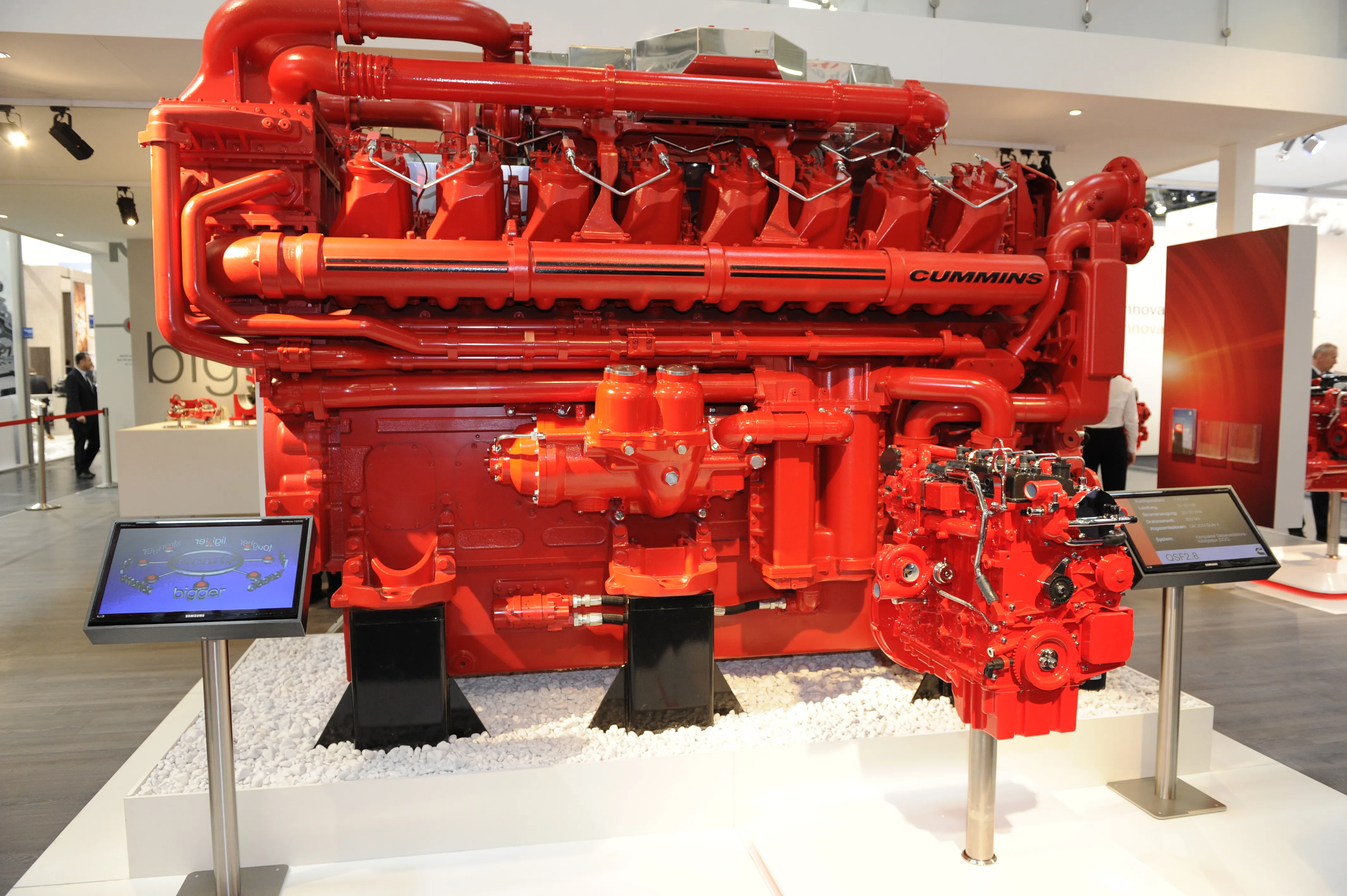

Cummins used bauma to reveal the QSF3.8 – a four-cylinder engine platform delivering a power range of 63-89kW – which is ready to meet Stage IV/Tier 4 Final emissions regulations. Using only SCR for its exhaust after-treatment process, the QSF3.8 avoids the need for either DOC or DPF as a result of using a high-efficiency catalyst to convert oxides of nitrogen at lower exhaust temperatures while requiring only low doses of DEF, said the company.

January 6, 2017

Read time: 2 mins

Using only SCR for its exhaust after-treatment process, the QSF3.8 avoids the need for either DOC or DPF as a result of using a high-efficiency catalyst to convert oxides of nitrogen at lower exhaust temperatures while requiring only low doses of DEF, said the company.

The high-efficiency SCR system also reduces the amount of cooled exhaust gas being recirculated through the engine, simultaneously reducing engine loading and placing lower demands on the cooling system.

“The QSF3.8 has the highest power output of any sub-four litre engine in its class,” said Tom Linebarger, Cummins chairman and CEO.

Although the new QSF3.8 is larger in displacement and meets stricter emissions standards than the QSB3.3, it achieves a similar fuel efficiency to its smaller stablemate while providing 10% more power and 18% more torque.

Stand: A4/315

%$Linker: