Cortec's MCI (Migratory Corrosion Inhibitor) coating for rebar is a water-based product that provides corrosion protection in outside storage as well as offering powerful corrosion resistance for embedded rebars. As a soft film, MCI is suitable for long-term indoor protection of up to five years as well as short- to medium-term, from six to 24 months, unsheltered outdoor protection. Cortec’s patented MCI technology rehabilitates existing concrete structures as well as extending the life of new structures.

July 7, 2016

Read time: 2 mins

Cortec's MCI (Migratory Corrosion Inhibitor) coating for rebar is a water-based product that provides corrosion protection in outside storage as well as offering powerful corrosion resistance for embedded rebars. As a soft film, MCI is suitable for long-term indoor protection of up to five years as well as short- to medium-term, from six to 24 months, unsheltered outdoor protection. Cortec’s patented MCI technology rehabilitates existing concrete structures as well as extending the life of new structures.

Cortec MCI products for concrete maintain structural integrity, rehabilitate vulnerable structures and alleviate environmental concerns. Cortec says that a unique feature of MCI is that the inhibitor will migrate a considerable distance through concrete to protect embedded ferrous metals.

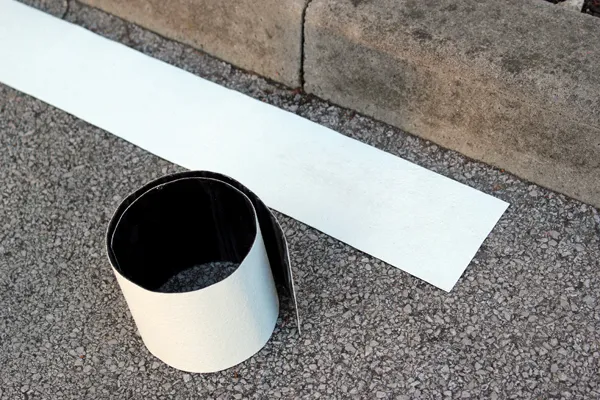

MCI coating for rebar protects steel, aluminium, cast iron and tin and does not affect concrete adhesion to rebar. This safe-to-use inhibitor cures to a soft film and eventually hardens.

The recommended dry film thickness range is 25-50 microns (1-2 mils). It can be removed by using an alkaline cleaner such as MCI-2060 if needed the coating works well in SO2 and H2S environment.

MCI coating for rebar can be used as is or be diluted with water up to 50%, as long as a 25-50 microns (1.0-2.0 mils) dry film thickness is reached on the surface to be protected. It can be applied by spray, brush, roll or dip.

Cortec MCI products for concrete maintain structural integrity, rehabilitate vulnerable structures and alleviate environmental concerns. Cortec says that a unique feature of MCI is that the inhibitor will migrate a considerable distance through concrete to protect embedded ferrous metals.

MCI coating for rebar protects steel, aluminium, cast iron and tin and does not affect concrete adhesion to rebar. This safe-to-use inhibitor cures to a soft film and eventually hardens.

The recommended dry film thickness range is 25-50 microns (1-2 mils). It can be removed by using an alkaline cleaner such as MCI-2060 if needed the coating works well in SO2 and H2S environment.

MCI coating for rebar can be used as is or be diluted with water up to 50%, as long as a 25-50 microns (1.0-2.0 mils) dry film thickness is reached on the surface to be protected. It can be applied by spray, brush, roll or dip.