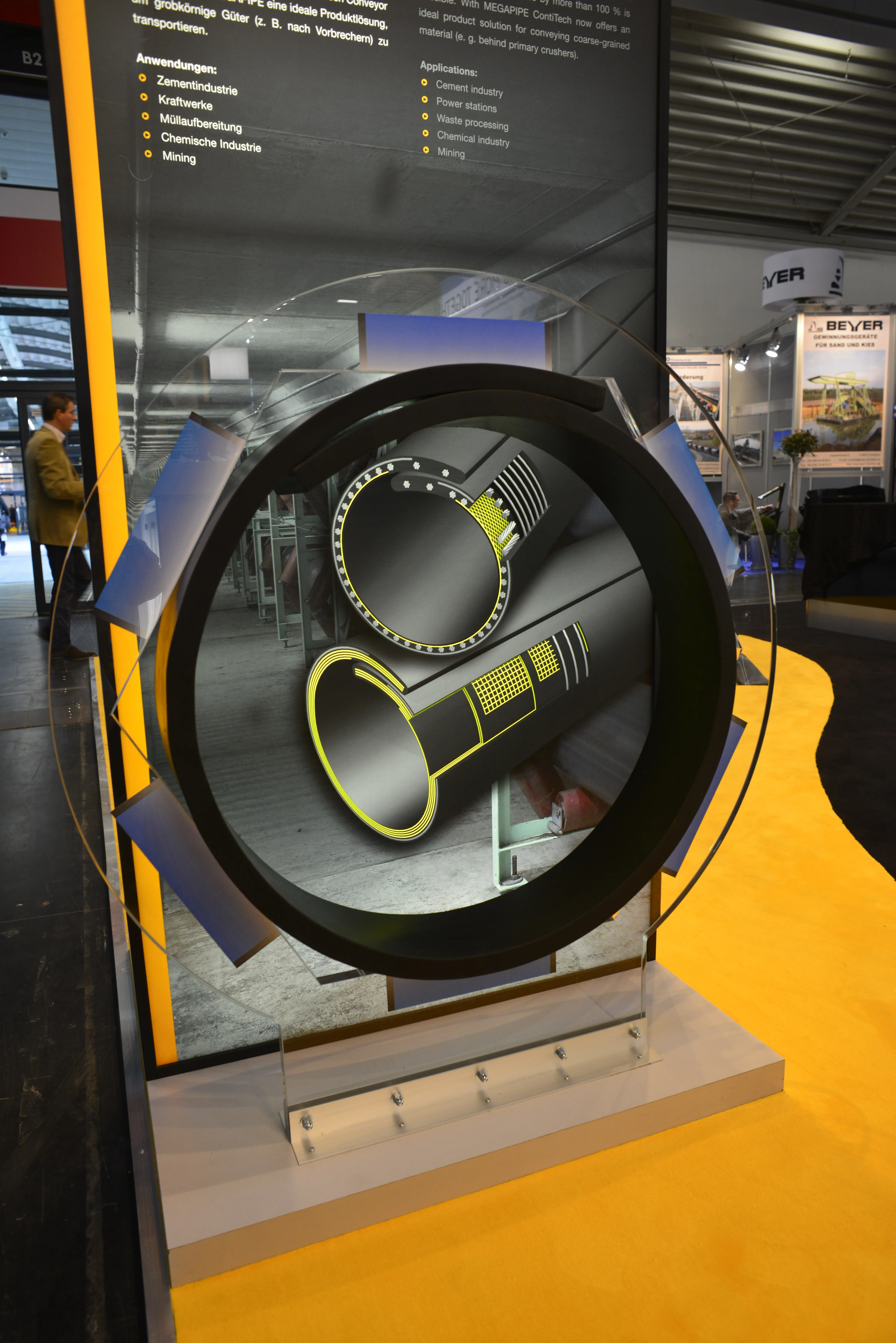

The ContiTech Conveyor Belt Group’s “innovative and environmentally friendly” conveyor belt solutions include the new MegaPipes. With an external diameter of up to 900mm, ContiTech claims the product doubles the capacities compared to conventional closed-trough belts and enables the transport of crushed ore downstream of the primary crusher or of bulky goods in the industrial sector applications.

January 6, 2017

Read time: 1 min

The 1527 ContiTech Conveyor Belt Group’s “innovative and environmentally friendly” conveyor belt solutions include the new MegaPipes.

With an external diameter of up to 900mm, ContiTech claims the product doubles the capacities compared to conventional closed-trough belts and enables the transport of crushed ore downstream of the primary crusher or of bulky goods in the industrial sector applications.

“Their special design allows the angle of inclination of the closed-trough belt systems to be increased by up to 45°, depending on the bulk material properties,” says ContiTech.

Another highlight is conveyor belts specially developed to transport hot goods, even at extremely high material temperatures. Through the use of an innovative insulation layer in the belt construction, heat transmission is lowered by up to 40°C, while the total weight of the conveyor belts is significantly reduced. The business unit is also presenting the low-stretch EPP textile belts CON-MONTEX and CON-BITEX as well as the TransCord conveyor belts.

With an external diameter of up to 900mm, ContiTech claims the product doubles the capacities compared to conventional closed-trough belts and enables the transport of crushed ore downstream of the primary crusher or of bulky goods in the industrial sector applications.

“Their special design allows the angle of inclination of the closed-trough belt systems to be increased by up to 45°, depending on the bulk material properties,” says ContiTech.

Another highlight is conveyor belts specially developed to transport hot goods, even at extremely high material temperatures. Through the use of an innovative insulation layer in the belt construction, heat transmission is lowered by up to 40°C, while the total weight of the conveyor belts is significantly reduced. The business unit is also presenting the low-stretch EPP textile belts CON-MONTEX and CON-BITEX as well as the TransCord conveyor belts.

Stand: B2.301/402

%$Linker: