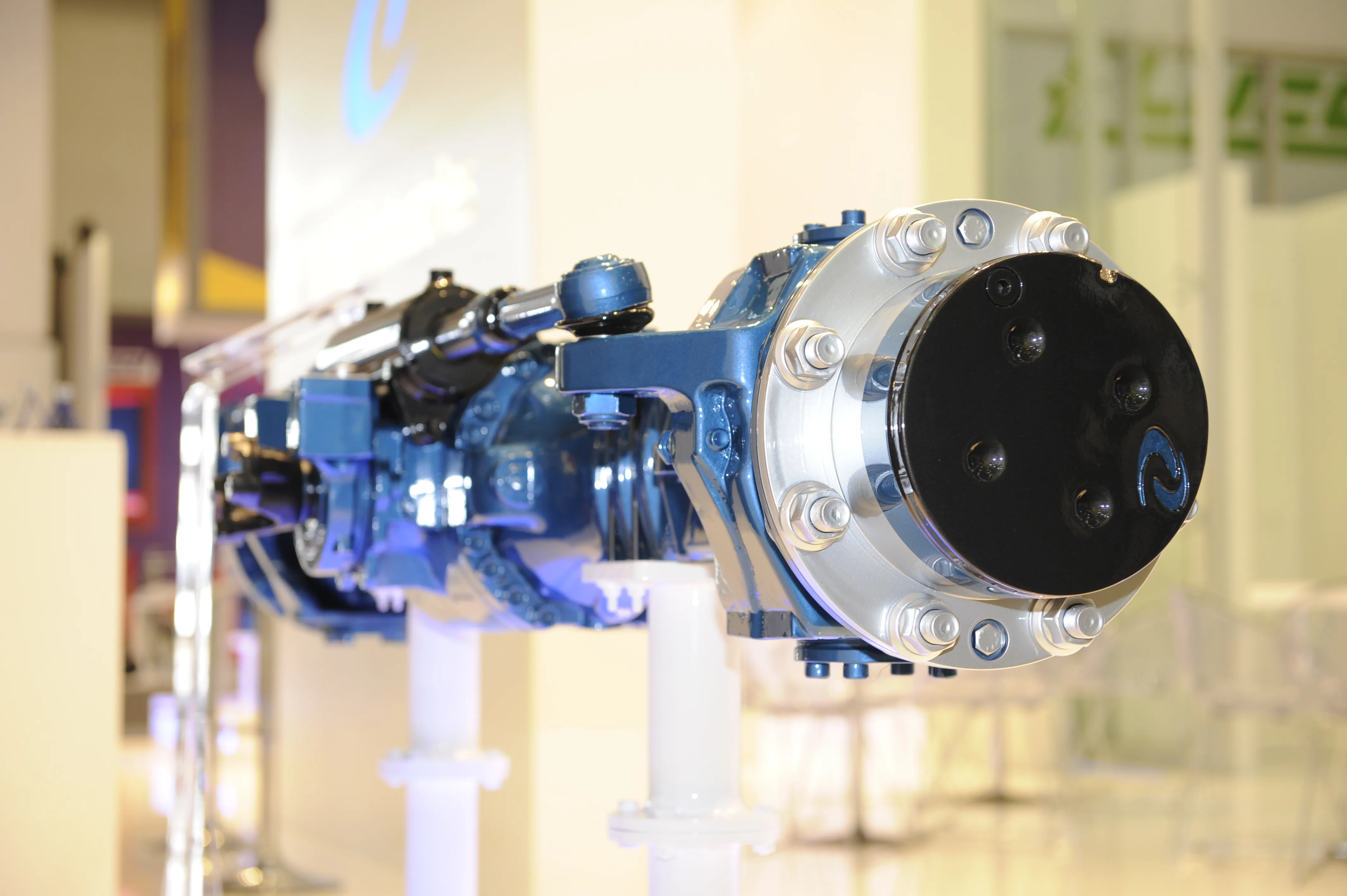

Comer Industries is using bauma to introduce its next generation of axles, wheel drives and heavy-duty track drives. Products on display at bauma include the series of new-generation axles starting from S-228, developed to provide high braking and efficient performance. The S-228-238 line was designed and built for applications including earthmoving. On display at bauma is the S-238, which has a dynamic load capacity of 12,000daN and a static load capacity of 22,000daN.

January 6, 2017

Read time: 2 mins

Products on display at bauma include the series of new-generation axles starting from S-228, developed to provide high braking and efficient performance. The S-228-238 line was designed and built for applications including earthmoving. On display at bauma is the S-238, which has a dynamic load capacity of 12,000daN and a static load capacity of 22,000daN.

The range has been developed to meet growing demand from manufacturers in terms of energy efficiency and reducing emissions, said Comer. A dedicated development team has worked on a thorough redesign that has covered the product line, supply chain and manufacturing.

The S-128 axle equips the new

The axle is claimed by Comer to provide the highest torque, braking and efficiency performance in its category. The modular axle has been designed for versatility. Applications include telehandlers, compact front loaders and backhoe loaders.

Comer Industries axles are also installed on the

Stand: A4.123/212

View more videosView more stories