Sweden’s

Demand for the company’s wear tools is currently strongest in construction, with the US the busiest region. Combi is also active in the dredging industry where it specialises in teeth and adapters for cutter dredgers. Dredging wear parts currently account for more than 40% of the company’s business, says Niclas Wechselberger, Combi technical manager.

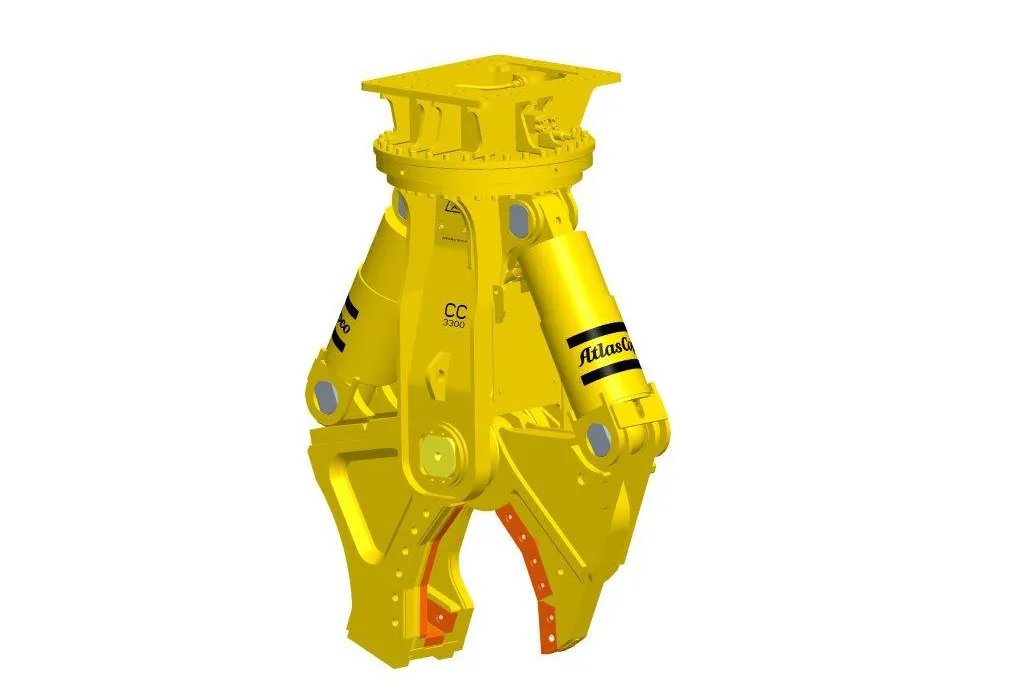

Combi Wear Parts extends range of teeth, adapters and accessories

Sweden’s Combi Wear Parts is extending its range of teeth, adapters and accessories for machines in the construction, mining and quarrying industries. At the smallest end, the company has introduced the W09 set of parts aimed at excavators in the widely used 25-35 tonnes range. Later in 2015, Combi plans to introduce a set of teeth, adapters and accessories at the largest end of its range for excavators of 300 tonnes and above.

January 6, 2017

Read time: 1 min