Colas is in discussions with clients who have suitable sites where the highway services provider could trial its solar road solution, Wattway. Colas says that the solar panels that make up the photovoltaic road surfacing technology are lightweight and strong and can be installed on top of an existing road surface.

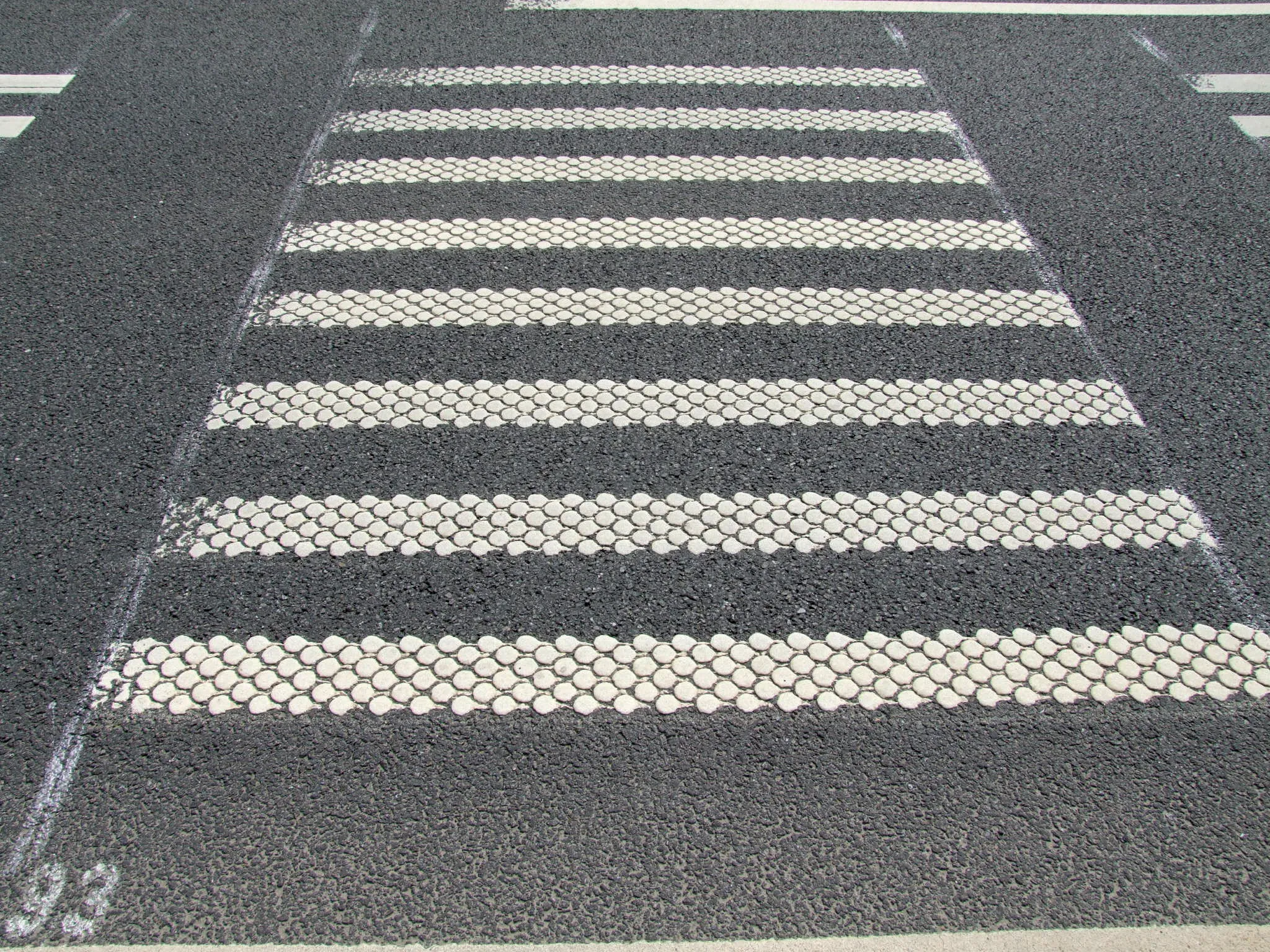

The panels are only 7mm thick and are applied on the surface with a high performance resin. A glass bead resin coating is also applied to allow the surface to provide acceptable frictional perf

October 26, 2016

Read time: 2 mins

The panels are only 7mm thick and are applied on the surface with a high performance resin. A glass bead resin coating is also applied to allow the surface to provide acceptable frictional performance without significantly affecting the efficiency of solar panels.

Carl Fergusson, Colas executive director of strategy and development, said the first trial is underway in France and UK trials will form part of about 100 world-wide. According to Colas, the power generated by Wattway has the potential to be used for highways and transportation infrastructure, such as variable message signs and street lights. But it also could be returned to the grid or used to supply energy to nearby homes and businesses. It is particularly well suited for smart-grids and short-circuit electricity production, as the need for new sources of energy and electric mobility continues to rise.

Each solar panel is an array of 15cm-wide cells making a very thin film of polycrystalline silicon that transforms solar energy into electricity. These extremely fragile photovoltaic cells are made tough by coating them in a watertight multilayer substrate composed of resins and polymers. This covering is translucent enough to allow sunlight to pass through but resistant enough to withstand even large-vehicle traffic.

The composite is also designed to adapt to the pavement’s natural thermal expansion. The surface that is in contact with vehicle tyres is treated to ensure skid-resistance equivalent to conventional asphalt mixes. Electrical connections can be installed at the edge of the carriageway or in ducts integrated in the panels themselves. Lastly, electronic circuit breakers ensure safety.