Spanish specialist CINTASA is aiming its new conveyor technologies at markets including quarrying and the cement sector. The firm’s latest tripper discharger and novel TEB vertical conveyor are said to offer proven and durable solutions for heavy duty applications.

March 14, 2013

Read time: 1 min

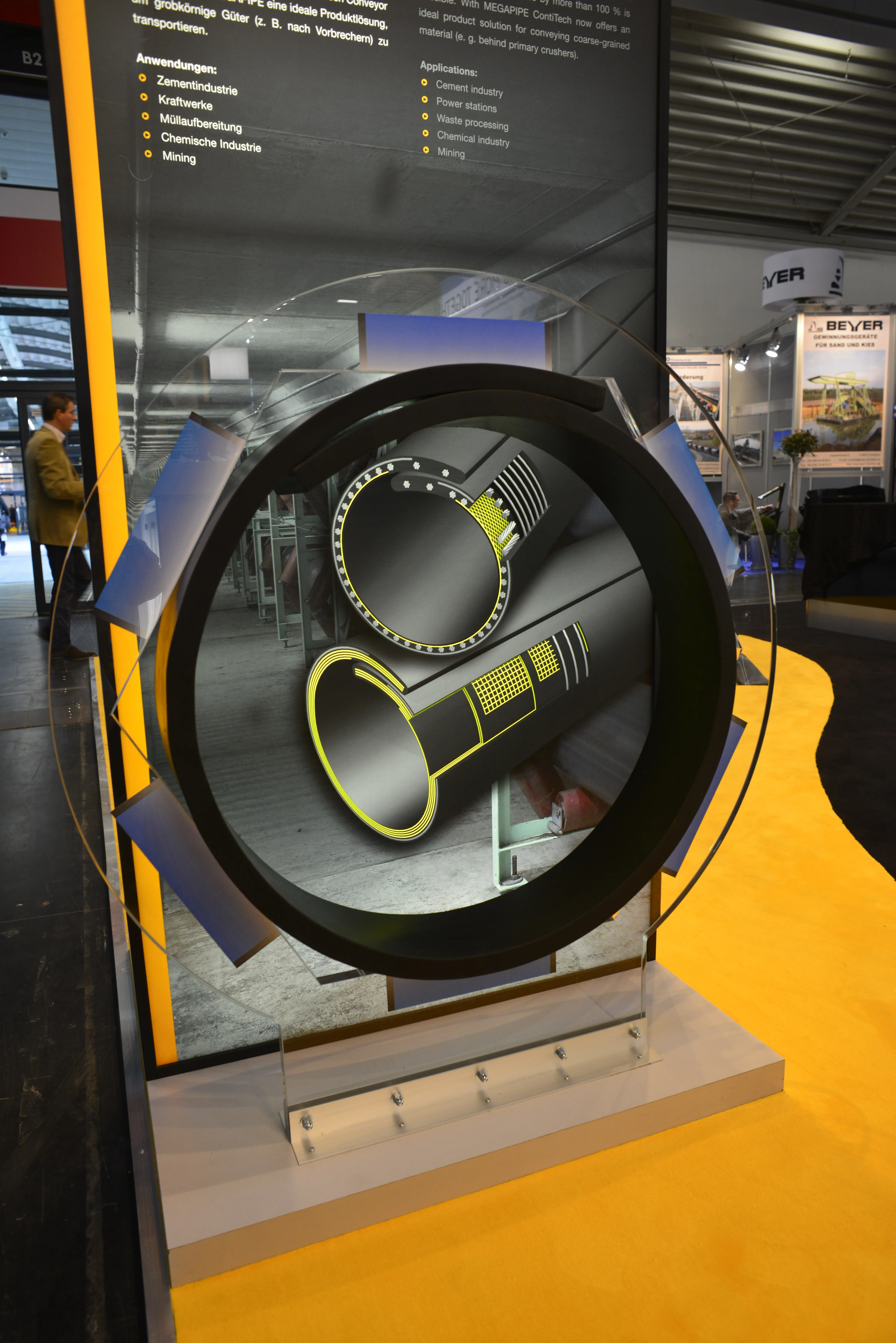

Spanish specialist 7222 Cintasa is aiming its new conveyor technologies at markets including quarrying and the cement sector. The firm’s latest tripper discharger and novel TEB vertical conveyor are said to offer proven and durable solutions for heavy duty applications. The firm is now offering a version of its rugged and robust TCL model with twin drives of 132kW and 800mm drum diameter. The transfer chute includes wear steel plates as well as a pair of blade scrapers, inspection doors and a level sensor. Another development is a tail section with a belt width of 1.2m, impact bars at loading zone, skirts with wear steel plates, rotation sensor, pull cord switches and other safety components. CINTASA’s TUL model is highly versatile and is designed for use in long distance conveyors or feeders.2 Internal <?xml version="1.0" encoding="utf-16"?><dictionary /> 2 11560 0 oLinkInternal <span class="oLinkInternal"><span class="oLinkInternal">View more videos</span></span> Video false /event-news/bauma-2013/video/ true false %>

Stand: B2.227

%$Linker:

%$Linker: