Caterpillar is unveiling four new machines at bauma China 2012 that have been developed specifically for the needs of the Chinese construction market. Two new hydraulic excavator models, one new wheeled loader and one off-highway truck will be on display at Caterpillar’s bauma China exhibit and these machines will expand the firm’s range of products for the Chinese market. The new Cat 312D GC Series 2 hydraulic excavator has been designed specifically for Chinese customers. This offers reduced operating cos

January 6, 2017

Read time: 2 mins

Caterpillar is unveiling four new machines at bauma China 2012 that have been developed specifically for the needs of the Chinese construction market.

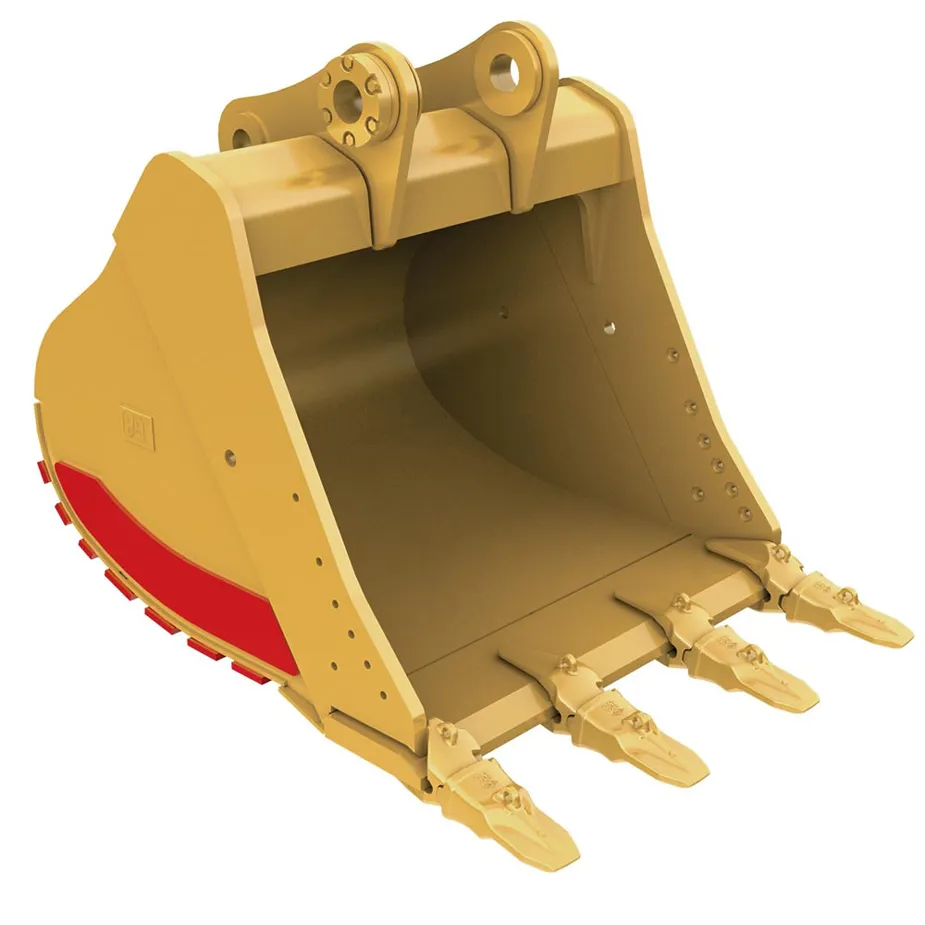

Two new hydraulic excavator models, one new wheeled loader and one off-highway truck will be on display atThe new Cat 312D GC Series 2 hydraulic excavator has been designed specifically for Chinese customers. This offers reduced operating costs, versatility, improved controllability, easy operation and a comfortable, redesigned operator station. The machine also has an updated engine, updated front linkage and changes to the hydraulic system. Also on display is the new Cat 326D L hydraulic excavator, designed to blend high productivity, versatility and low operating costs. The 25.6tonne 326D L is powered by using the Cat C7 engine rated at 140kW, with heavy-duty upper and lower structures and a spacious cab.

The Cat 986H wheeled loader is built for durability with field-proven Cat components to lower cost/tonne. Load-sensing hydraulics and standard torque converter lock-up clutch offer maximum fuel efficiency. The 986H has a 42.5tonne operating weight to form an effective pass match with the Cat 770G and 772G trucks and maximise productivity. The new Cat 772G rigid-frame truck has three body options designed to last the life of the truck and to meet hauling needs.

%$Linker: