Case has developed a concept wheeled loader to showcase new and developing technologies. The “Impact” is fully electric and features Case’s semi-autonomous “click & dig” system, but the most notable thing about the machine it its silhouette - it has no cab. It has been designed for remote operation.

“We can imagine in the future that we can drive the machine fully automatically from a kind of site control lounge,” explained Fabrizio Cepollina, head of construction for EMEA Case. “It could be interesting for dangerous areas such as demolition.”

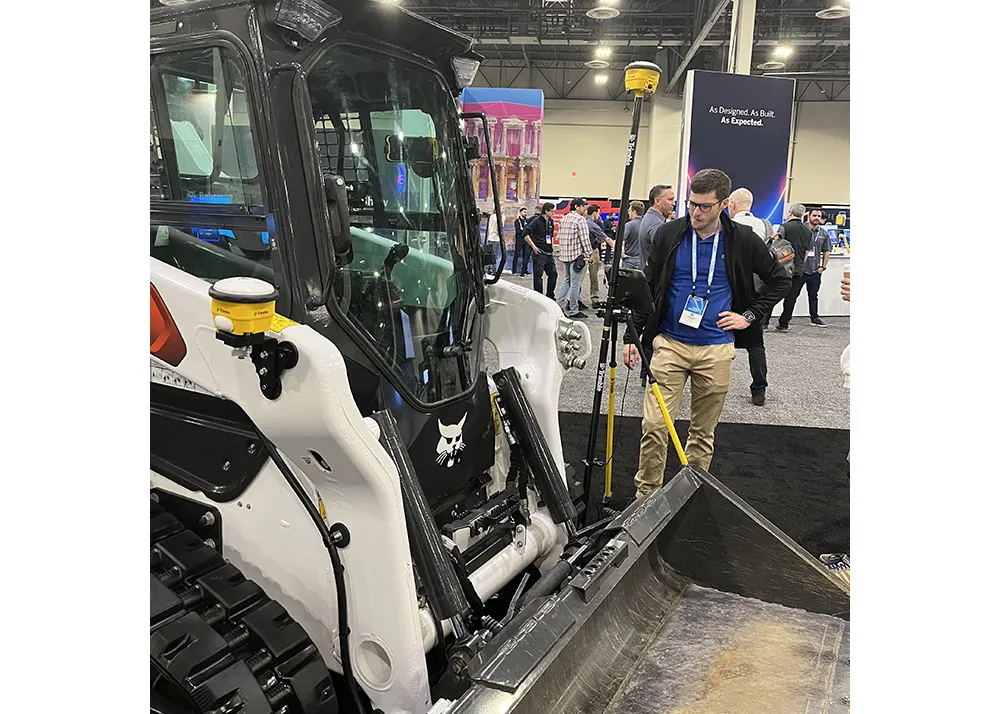

Case is working in partnership with several companies to develop a raft of digital tools, some of which are already being deployed in its latest machines: satellite positioning with sister company Hemisphere; autonomous and semi-autonomous operation with Gravis Robotics; and AI technology such as real-time obstacle detection with Cyient.

“Digitalisation is everywhere today, for us it means machine guidance and control systems, semi-automation, and on-board AI which is the new frontier,” said Cepollina.

Among new Case machines which benefit from digital enhancement are the CX38D compact excavator which deploys Hemisphere’s GNSS technology for real-time positioning and the 1021G+ X-DRIVE wheeled loader which incorporates click & dig automation.