Case is increasing its presence in the earthmoving sector with the launch of a three-model range of upgraded M Series dozers, up from two models in the previous generation. The 1150M, 1650M and 2050M weigh in at 13-20tonnes and all feature Tier 4 Interim/Stage IIIB-compliant FPT diesel engines with selective catalytic reduction (SCR) technology. Case claims that the use of SCR results in lower fuel consumption, up to 10.5% less in the case of these dozers, while the 1150M and 2050M benefit from a 9% power i

January 6, 2017

Read time: 2 mins

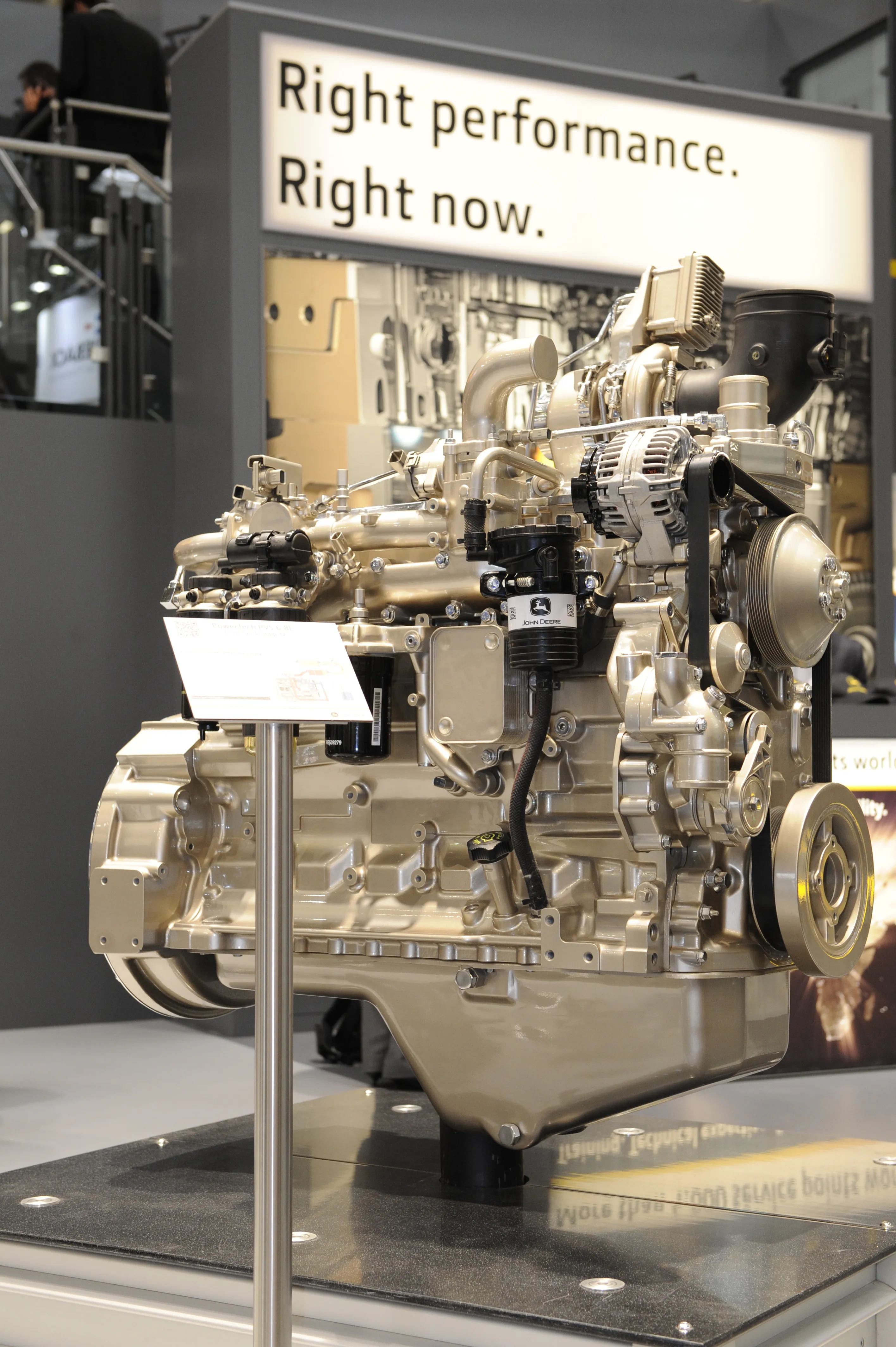

The 1150M, 1650M and 2050M weigh in at 13-20tonnes and all feature Tier 4 Interim/Stage IIIB-compliant FPT diesel engines with selective catalytic reduction (SCR) technology.

Case claims that the use of SCR results in lower fuel consumption, up to 10.5% less in the case of these dozers, while the 1150M and 2050M benefit from a 9% power increase. The 1650M offers 16% more power than previous models, which Case claims results in a 19% increase in productive efficiency.

The two larger models use a V-shaped cooling package to provide increased air flow through the radiators. With a hydraulically-driven, reversible cooling fan, there is less requirement to clean radiator cores manually and a reduction in noise as the fans only operate when required. Hydrostatic transmissions with improved oil cooling are used on all three machines.

Case claims market-leading drawbar pull for the three dozers – 213kN for the 1150M, 311kN for the 1650M and 374kN for the 2050M.

Operators can choose between three reversing and steering mode settings to suit the application or their driving style. In addition, the control joystick can be used to select up to 15 speed settings or the Case Proportional Doze Control (PDC), which delivers increased accuracy in fine grading.

Stand: F7.713/3

%$Linker: