The Atlas Copco Group is to modify its business area structure to "strengthen the focus on specific product and customer segments."

March 1, 2012

Read time: 1 min

The 161 Atlas Copco Group is to modify its business area structure to “strengthen the focus on specific product and customer segments.”

From 1 July, the group will have four business areas instead of three, including a dedicated business area for construction equipment and related services.

Atlas Copco’s divisions for portable compressors and generators, road construction equipment and construction tools will join forces in the new Construction Technique business area.

Divisions with underground and surface drilling products, crushing, loading and hauling, and exploration equipment will work under the umbrella of Mining and Rock Excavation Technique.

Both these business areas will create dedicated service divisions.

Compressor Technique will focus on stationary equipment for air and gas and related service, while Industrial Technique remains unchanged.

“With more focused business areas, each will have a strong platform from which they can develop the offering for their customers,” says Ronnie Leten, President and CEO of the Atlas Copco Group.

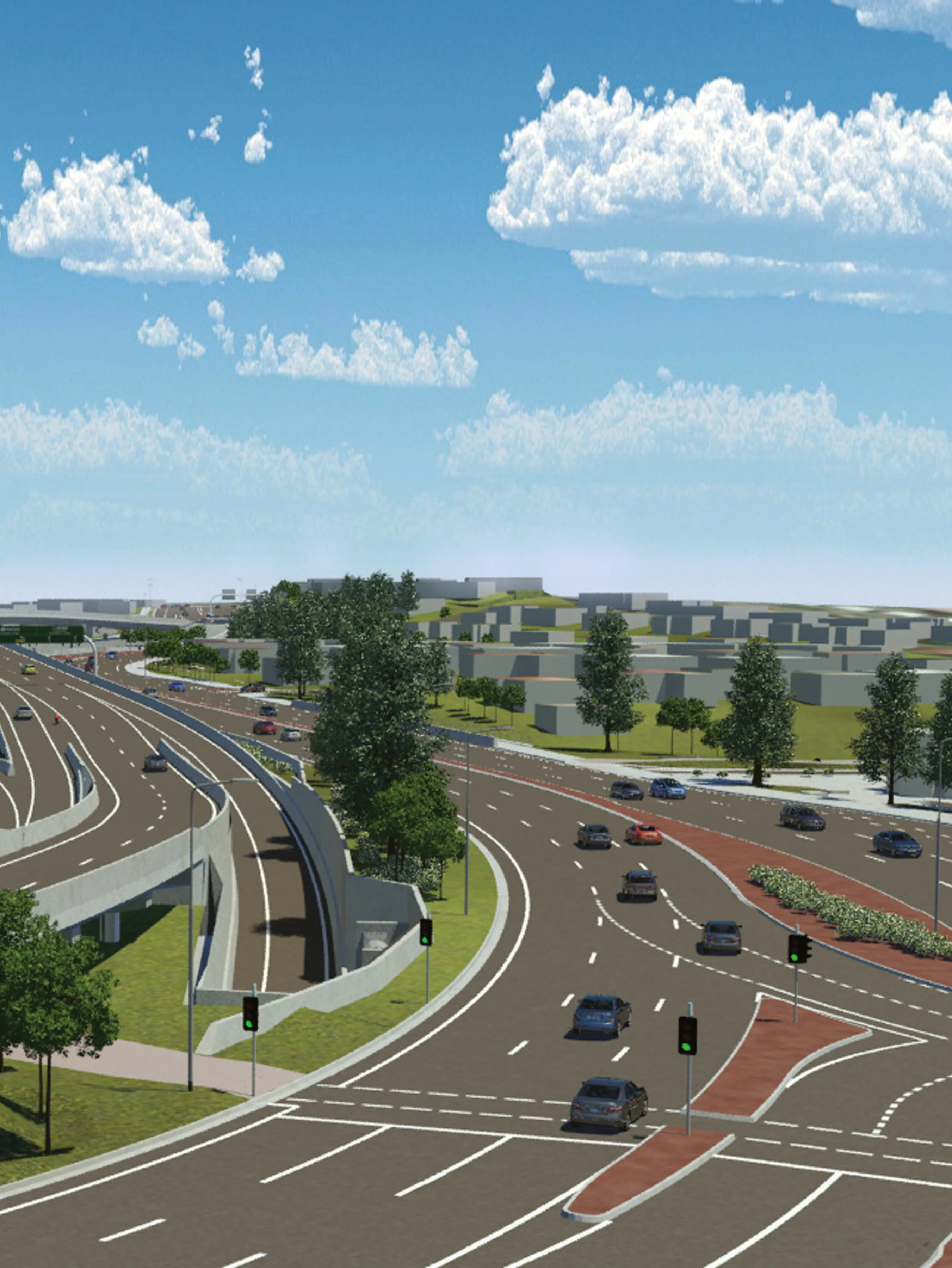

“The modified structure also allows us to better capture the sales and service synergies between our construction businesses and capitalise on the future growth of construction projects around the world, especially in emerging markets.”

From 1 July, the group will have four business areas instead of three, including a dedicated business area for construction equipment and related services.

Atlas Copco’s divisions for portable compressors and generators, road construction equipment and construction tools will join forces in the new Construction Technique business area.

Divisions with underground and surface drilling products, crushing, loading and hauling, and exploration equipment will work under the umbrella of Mining and Rock Excavation Technique.

Both these business areas will create dedicated service divisions.

Compressor Technique will focus on stationary equipment for air and gas and related service, while Industrial Technique remains unchanged.

“With more focused business areas, each will have a strong platform from which they can develop the offering for their customers,” says Ronnie Leten, President and CEO of the Atlas Copco Group.

“The modified structure also allows us to better capture the sales and service synergies between our construction businesses and capitalise on the future growth of construction projects around the world, especially in emerging markets.”