The lower angle of Caterpillar Work Tools’ new line of buckets for the E-series Hydraulic Excavators are said to concentrate the power of the machine across a smaller surface, offering less resistance to the material flow into and around the bucket resulting in a smoother and faster dig cycle. In addition, ‘Tip forward’ - the tip position that opens up the mouth of the bucket and lengthens the floor - has been moved towards the operator. This is said to improve both material flow into the bucket and visibi

January 6, 2017

Read time: 2 mins

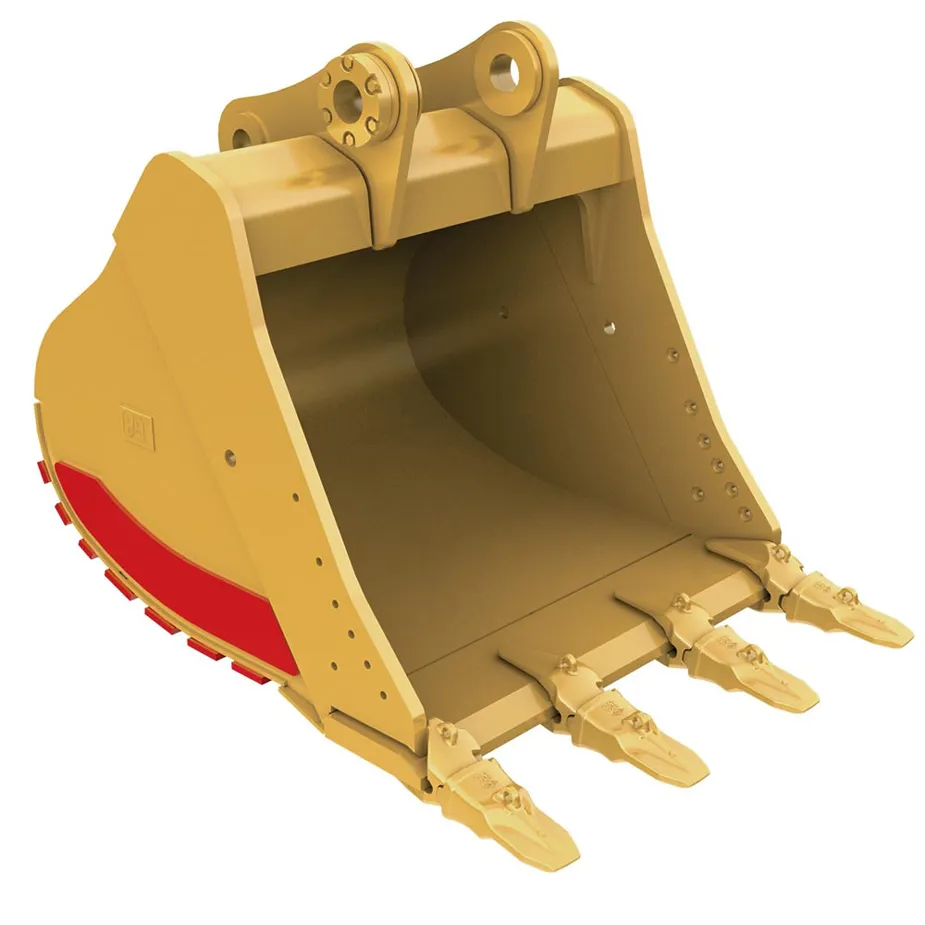

The lower angle of 178 Caterpillar Work Tools’ new line of buckets for the E-series Hydraulic Excavators are said to concentrate the power of the machine across a smaller surface, offering less resistance to the material flow into and around the bucket resulting in a smoother and faster dig cycle.

In addition, ‘Tip forward’ - the tip position that opens up the mouth of the bucket and lengthens the floor - has been moved towards the operator. This is said to improve both material flow into the bucket and visibility to enable the operator to load faster and more efficiently.

These two geometry improvements are also said by Cat to help deliver better cycle times and reduce operator fatigue.

Cat says it has strengthened its buckets’ construction and designed it to compliment improved excavator performance. This, the firm says, results in longer bucket life and lower fuel burn per tonne.

Four standard bucket categories are offered by Cat for excavators. Each category is based on intended bucket durability when used for the recommended material and application. General duty buckets are for digging in low impact, lower abrasion materials such as dirt. Heavy duty buckets are for operating in a wide range of impact and abrasion conditions including mixed dirt, clay, sand and gravel. Severe duty buckets are designed for higher abrasion conditions such as shot rock and sandstone. Finally, Extreme Duty buckets are said to be ideal for very high abrasion conditions including high quartzite granite.

Cat supports its work tools with what it stresses are a comprehensive range of pre and after sales services that cover everything from advice on work tool selection to operator training, equipment management, and a range of financial and insurance products.

2 Internal 2 4824 0 oLinkInternal <span class="oLinkInternal"><span class="oLinkInternal">View more videos</span></span> Video false /event-news/intermat-2012/video/ true false %>

In addition, ‘Tip forward’ - the tip position that opens up the mouth of the bucket and lengthens the floor - has been moved towards the operator. This is said to improve both material flow into the bucket and visibility to enable the operator to load faster and more efficiently.

These two geometry improvements are also said by Cat to help deliver better cycle times and reduce operator fatigue.

Cat says it has strengthened its buckets’ construction and designed it to compliment improved excavator performance. This, the firm says, results in longer bucket life and lower fuel burn per tonne.

Four standard bucket categories are offered by Cat for excavators. Each category is based on intended bucket durability when used for the recommended material and application. General duty buckets are for digging in low impact, lower abrasion materials such as dirt. Heavy duty buckets are for operating in a wide range of impact and abrasion conditions including mixed dirt, clay, sand and gravel. Severe duty buckets are designed for higher abrasion conditions such as shot rock and sandstone. Finally, Extreme Duty buckets are said to be ideal for very high abrasion conditions including high quartzite granite.

Cat supports its work tools with what it stresses are a comprehensive range of pre and after sales services that cover everything from advice on work tool selection to operator training, equipment management, and a range of financial and insurance products.

%$Linker:

Hall: 5B Stand: J023

%$Linker: