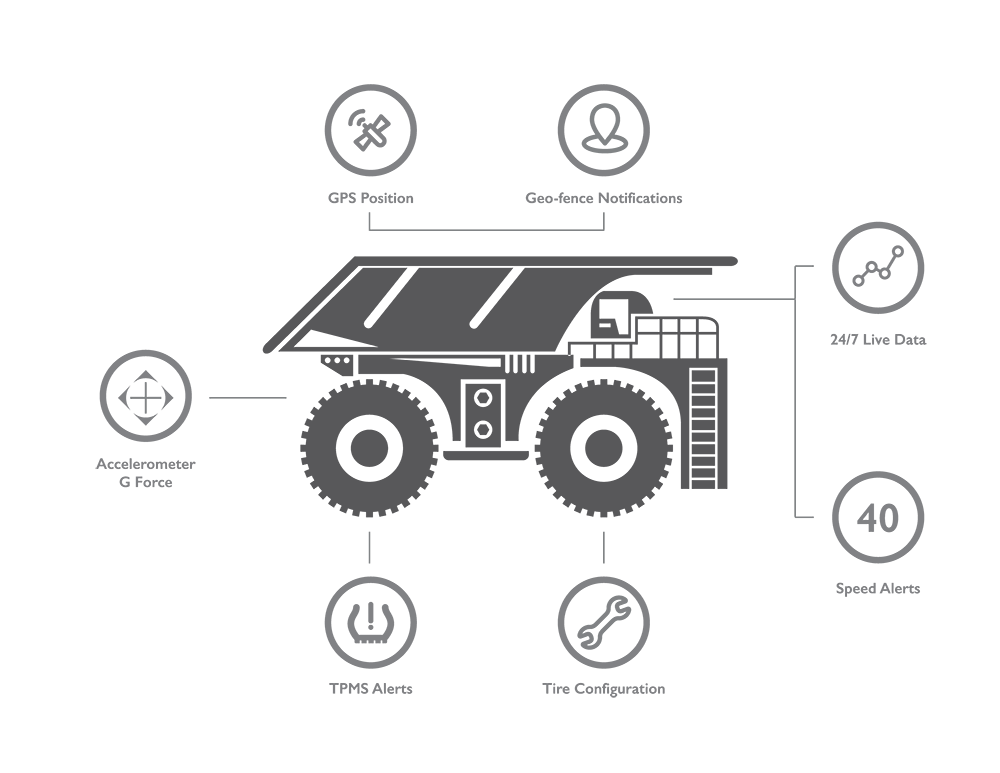

A globally renowned provider of tyre management solutions for the off-highway vehicle market, the iTrack platform offers a comprehensive tyre pressure monitoring system (TPMS) specially designed for mining tyres. In addition to tyre temperature and pressure monitoring, iTrack provides customisable geofencing, speed alerts and more to help mining customers optimise their operations for increased productivity and profitability.

“This acquisition helps move Bridgestone closer to its goal of becoming a leader in sustainable and advanced mobility solutions,” said Tomohiro Kusano, vice president and senior officer, responsible for Bridgestone’s G-MAA (Mining, Aircraft, Agriculture) Solutions Business at Bridgestone Corporation. “As a global solutions provider, Bridgestone will create new value for our customers by delivering tyre and mobility-related data that enhances their operations.”

Bridgestone entered into a joint collaboration agreement with Transense in August 2019 and began referring off-highway tyre customers to iTrack at that time. Customer response to the tyre management platform is said to have been overwhelmingly positive. Bridgestone will expand this offering to additional off-highway tyre customers as it fully integrates the solution into its portfolio. To ensure a seamless transition, all iTrack employees will join Bridgestone as part of the acquisition.