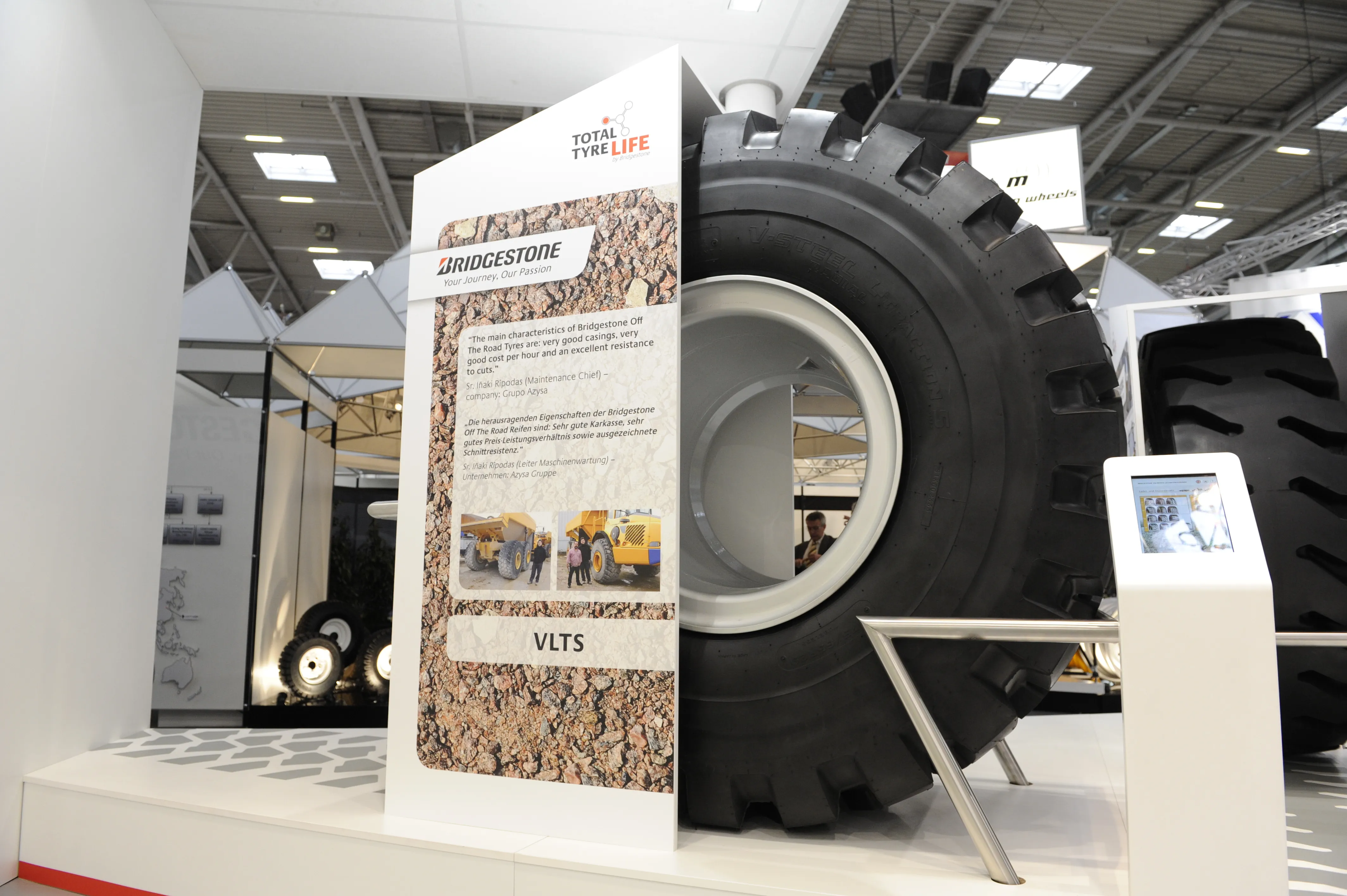

The VLTS traction tyre from Bridgestone has been introduced with an increased tread depth to give greater longevity in ADT applications. With 60mm deep tread blocks in place of 47.5mm for the standard tyre, the VLTS in 875/65 R29 is a low-profile replacement for the 29.5 R25 tyre among 40tonne class ADTs.

April 17, 2013

Read time: 1 min

The VLTS traction tyre from 175 Bridgestone has been introduced with an increased tread depth to give greater longevity in ADT applications.

With 60mm deep tread blocks in place of 47.5mm for the standard tyre, the VLTS in 875/65 R29 is a low-profile replacement for the 29.5 R25 tyre among 40tonne class ADTs.

The aspect ratio of the 875/65 tyre affords a much wider – and larger – contact patch, offering greater flotation characteristics while maintaining a comparable overall height to that of the 29.5 R25.

The VLTS is also available in a 750/65 R25 to replace 23.5 R25 in the 30tonne ADT class, offering 7mm more tread depth than the standard tyre.

View more videos

View more stories

With 60mm deep tread blocks in place of 47.5mm for the standard tyre, the VLTS in 875/65 R29 is a low-profile replacement for the 29.5 R25 tyre among 40tonne class ADTs.

The aspect ratio of the 875/65 tyre affords a much wider – and larger – contact patch, offering greater flotation characteristics while maintaining a comparable overall height to that of the 29.5 R25.

The VLTS is also available in a 750/65 R25 to replace 23.5 R25 in the 30tonne ADT class, offering 7mm more tread depth than the standard tyre.

View more videos

View more stories