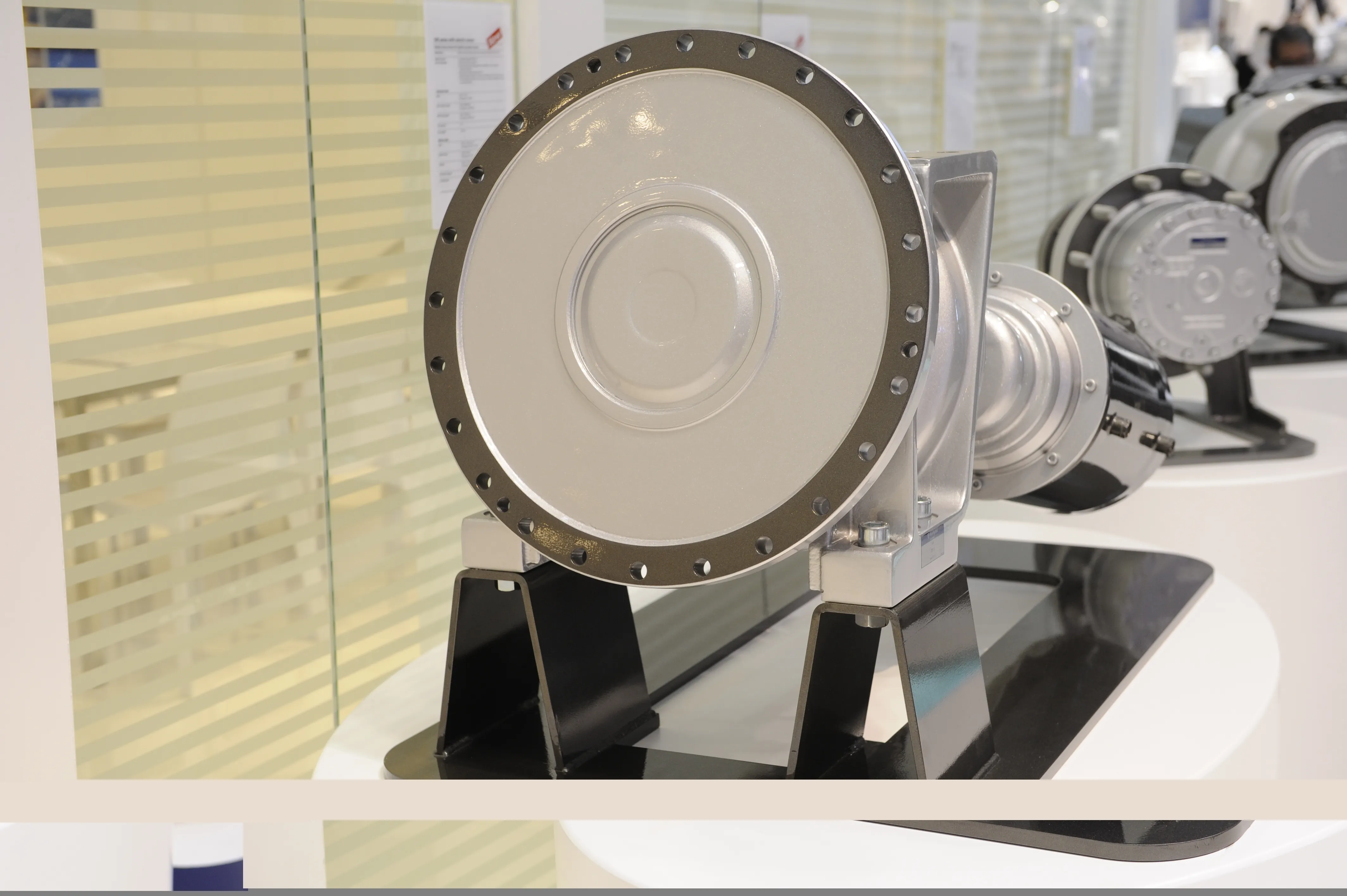

Bonfiglioli has developed an electric drum drive for the new hybrid truck mixer from CIFA, the concrete equipment specialist owned by Chinese manufacturer Zoomlion. The 500 series drum drive with electric motor offers drum rotation speeds from 15-22rpm and is suited to mixer capacities from 6-14m3. The drivetrain relies on an AC induction motor to turn the drum, which gets its power from an on-board battery pack. The electric drum drive can also be powered by mains electricity – the latter can be plugged in

April 18, 2013

Read time: 2 mins

The 500 series drum drive with electric motor offers drum rotation speeds from 15-22rpm and is suited to mixer capacities from 6-14m3. The drivetrain relies on an AC induction motor to turn the drum, which gets its power from an on-board battery pack. The electric drum drive can also be powered by mains electricity – the latter can be plugged in when the truck mixer has arrived on site.

Key advantages include lower noise levels and reduced engine emissions, said Bonfiglioli. Using an electric motor also allows the vehicle’s engine to be stopped when on site, offering a benefit to urban locations where noise pollution is a consideration.

The system also includes a smaller capacity DC motor, which is fitted as an emergency back-up. Should the AC system fail when the truck mixer is laden, the DC motor allows the drum to be emptied before concrete starts to harden inside the drum.

Stand: A4.117

%$Linker: