Trackpads made by BLS Enterprises for use on Wirtgen milling machines have had their first bauma outing. Component specialist BLS Enterprises is offering a durable replacement track that is a direct replacement for the EPS system. Its distinctive range of blue-coloured pads has been developed to last 15% to 30% longer than conventional polyurethane units. “We want to be known as the people who make the blue pads,” said BLS president Barry Stoughton. Blue pads are the longest-lasting pads, he said. The two-p

January 6, 2017

Read time: 2 mins

Trackpads made by 5058 BLS Enterprises for use on 2395 Wirtgen milling machines have had their first 688 Bauma outing.

Component specialist BLS Enterprises is offering a durable replacement track that is a direct replacement for the EPS system.

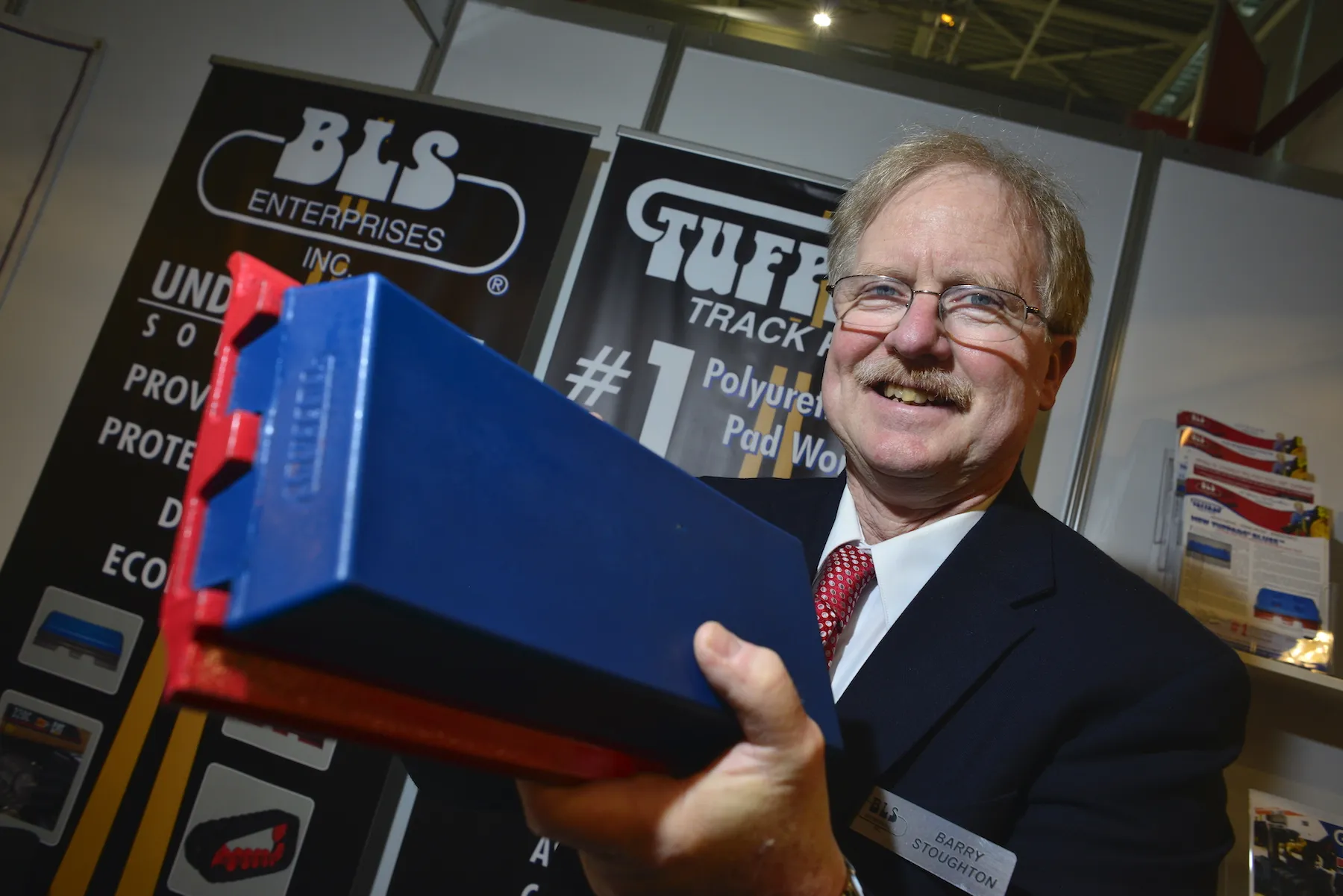

Its distinctive range of blue-coloured pads has been developed to last 15% to 30% longer than conventional polyurethane units. “We want to be known as the people who make the blue pads,” said BLS president Barry Stoughton. Blue pads are the longest-lasting pads, he said.

The two-part pad system allows the pad to bolt directly on to the track. Studs welded into metal inserts inside the pads allow them to be dropped into place, then tightened up from below. Long life and durability are claimed, as well as ease of replacement. The advantages of two-part systems is that only the polyurethane pads need replacing, with the metal remaining in place.

BLS Enterprises aims to provide a one-stop shop for milling. In addition to trackpads, it provides the hardware, sprockets, idlers, rollers and chains needed.

It teamed up at bauma with two complementary businesses, sharing a stand with Kenco Engineering and Keystone Engineering, which make other parts for milling machines.2 Internal <?xml version="1.0" encoding="utf-16"?><dictionary /> 2 11560 0 oLinkInternal <span class="oLinkInternal"><span class="oLinkInternal">View more videos</span></span> Video false /event-news/bauma-2013/video/ true false %>

Component specialist BLS Enterprises is offering a durable replacement track that is a direct replacement for the EPS system.

Its distinctive range of blue-coloured pads has been developed to last 15% to 30% longer than conventional polyurethane units. “We want to be known as the people who make the blue pads,” said BLS president Barry Stoughton. Blue pads are the longest-lasting pads, he said.

The two-part pad system allows the pad to bolt directly on to the track. Studs welded into metal inserts inside the pads allow them to be dropped into place, then tightened up from below. Long life and durability are claimed, as well as ease of replacement. The advantages of two-part systems is that only the polyurethane pads need replacing, with the metal remaining in place.

BLS Enterprises aims to provide a one-stop shop for milling. In addition to trackpads, it provides the hardware, sprockets, idlers, rollers and chains needed.

It teamed up at bauma with two complementary businesses, sharing a stand with Kenco Engineering and Keystone Engineering, which make other parts for milling machines.

%$Linker: