BI Conseil is aiming for Swiss watches to become as standard as hard hats in preventing injury on site.

January 6, 2017

Read time: 2 mins

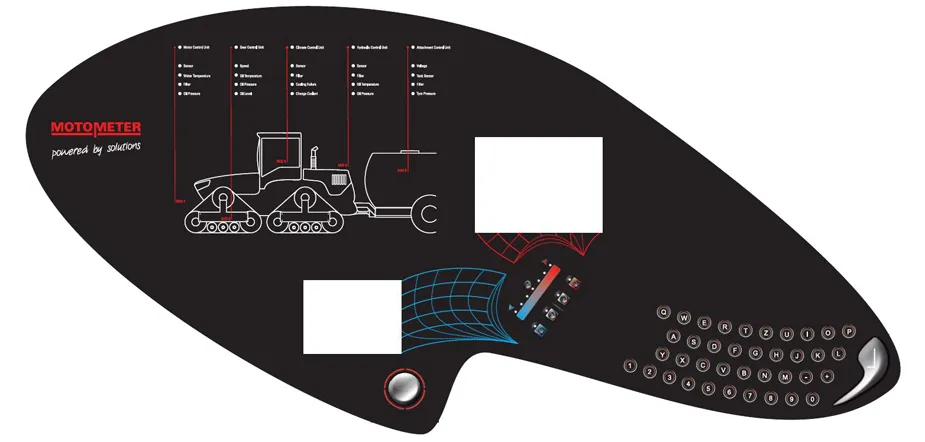

The company will be showing INTERMAT 2012 visitors a system aimed at preventing moving vehicles from hitting oblivious site workers. The worker wears a rugged Swiss-made watch, which issues a strong vibration in case of immediate danger to ensure that the worker reacts instantly to the threat.

All of the development has been carried out by BI Conseil and its collaborators in Switzerland, with work taking place in Geneva and at the Parc Scientifique Y-Parc in Yverdon les Bains Vaud. Pilot site trials are set to take place from June.

A radar system detects locations of the people and equipment. The watch houses sophisticated circuitry including a multi-axis antenna to determine the position accurately as the worker moves.

How people react has been a key consideration in developing the system, as too has been the need to ensure that it could distinguish between objects and humans. The worker must react immediately and take action to get out of the way. However, workers tend to ignore audible alarms, said BI Conseil & Associates senior partner Marc de Gagné. They often think that the alarm is for someone else, he said, and back-alarms on trucks are so common that few will pay attention. But ignoring the alarms can have fatal consequences.

The system has been designed to detect the true risk of collision – while avoiding false alarms - and warn the worker in danger by provoking a spontaneous reaction of self-defence.

Development has taken several years. The system makes use of a custom-designer radar system, which has been developed for precision over short distances. The system warns the vehicle driver, but does not rely on drivers’ reaction times as these may be too slow to prevent an accident. Central to the development was the need to convey the urgency of the situation to the person in danger. The best and most effective way is to create a reflex reaction on the part of the worker, said de Gagné.

Its advantage is that it focuses directly on each worker concerned, said de Gagné. There can be no doubt – if a worker gets "buzzed", then he or she is in immediate danger.

%$Linker:

Hall: 5A Stand: D046

%$Linker: