Astec, an Astec Industries company, and one of North America’s leading manufacturers of state-of-the-art asphalt plants, will exhibit as part of the Astec Industries stand. On display will be a one-eighth scale model of a complete Astec M-Pack relocatable asphalt facility. Since its debut at ConExpo 2005, the award-winning Astec model has garnered acclaim by putting an entire asphalt plant on a human scale with remarkable attention to detail. “The innovative M-Pack facility features the Astec exclusive Doub

January 6, 2017

Read time: 2 mins

Astec, an 681 Astec Industries company, and one of North America’s leading manufacturers of state-of-the-art asphalt plants, will exhibit as part of the Astec Industries stand.

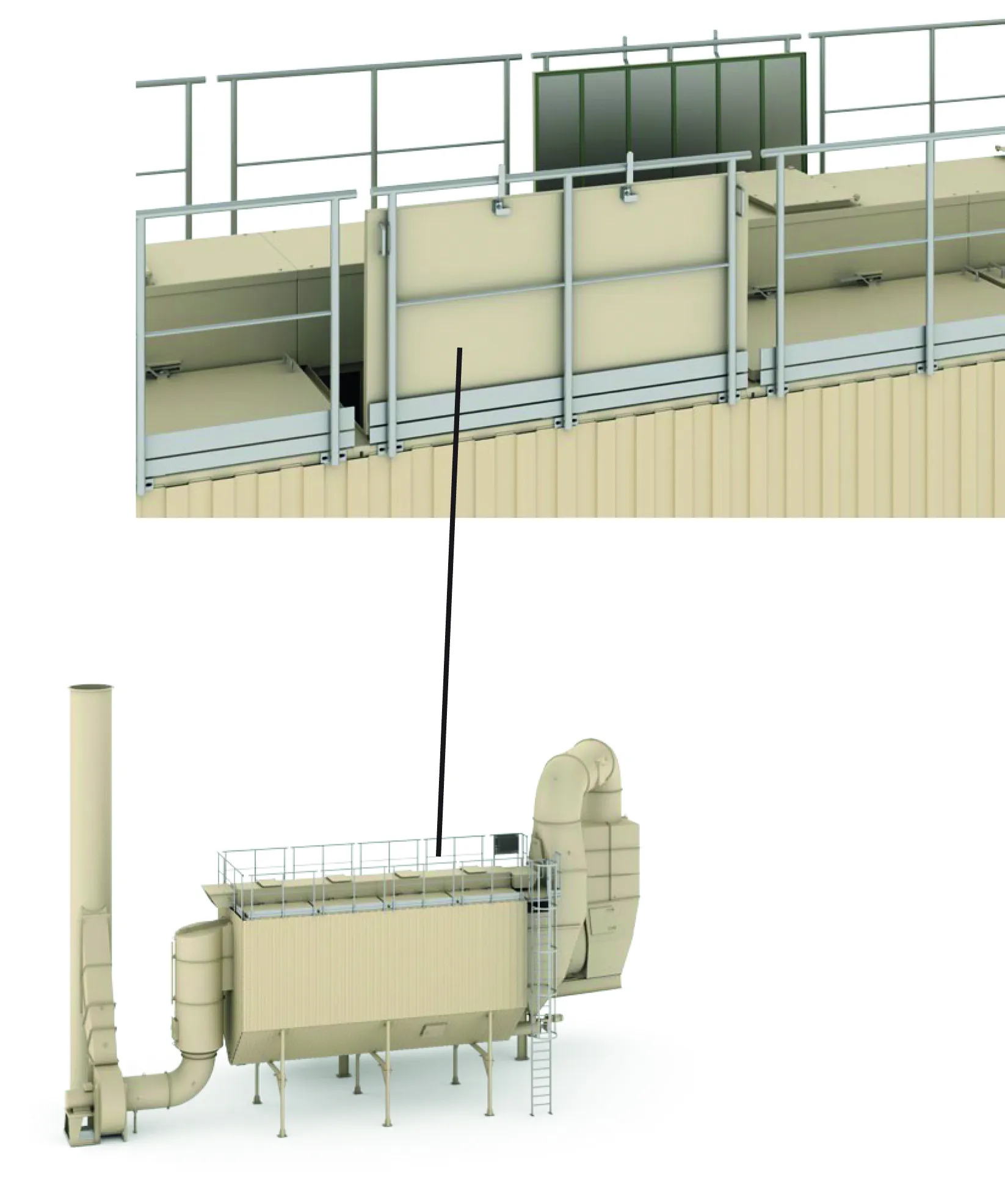

On display will be a one-eighth scale model of a complete Astec M-Pack relocatable asphalt facility.

Since its debut at ConExpo 2005, the award-winning Astec model has garnered acclaim by putting an entire asphalt plant on a human scale with remarkable attention to detail.

“The innovative M-Pack facility features the Astec exclusive Double Barrel technology and new generation long-term storage silos,” says Astec.

“Created for producers who don’t move often but want to reap the benefits of fast plant setup when they do, the M-Pack is designed with self-contained, skid-mounted modules for maximum efficiency and cost savings. Another added benefit is the minimal site preparation costs that are required to accommodate an Astec M-Pack Double Barrel plant.”

Also on display will be an actual full-size Astec Double Barrel drum dryer/mixer. The Double Barrel dryer/drum mixer combines the functions of a dryer and a continuous-process mixer in one compact, efficient system. Drying of the virgin aggregate is the first step in the process and takes place inside the inner drum. Mixing of aggregate and other ingredients follows, which happens in the outer chamber of the stationary shell. Each drying and mixing step will be highlighted on this drum.

“Equally important to the state-of-the-art technology and high quality that every Astec plant offers, is their commitment to after-sales service, technical support and parts support. Service personnel are dispatched globally to support the set up and commissioning of plants as well as to train plant operators,” says the company.

On display will be a one-eighth scale model of a complete Astec M-Pack relocatable asphalt facility.

Since its debut at ConExpo 2005, the award-winning Astec model has garnered acclaim by putting an entire asphalt plant on a human scale with remarkable attention to detail.

“The innovative M-Pack facility features the Astec exclusive Double Barrel technology and new generation long-term storage silos,” says Astec.

“Created for producers who don’t move often but want to reap the benefits of fast plant setup when they do, the M-Pack is designed with self-contained, skid-mounted modules for maximum efficiency and cost savings. Another added benefit is the minimal site preparation costs that are required to accommodate an Astec M-Pack Double Barrel plant.”

Also on display will be an actual full-size Astec Double Barrel drum dryer/mixer. The Double Barrel dryer/drum mixer combines the functions of a dryer and a continuous-process mixer in one compact, efficient system. Drying of the virgin aggregate is the first step in the process and takes place inside the inner drum. Mixing of aggregate and other ingredients follows, which happens in the outer chamber of the stationary shell. Each drying and mixing step will be highlighted on this drum.

“Equally important to the state-of-the-art technology and high quality that every Astec plant offers, is their commitment to after-sales service, technical support and parts support. Service personnel are dispatched globally to support the set up and commissioning of plants as well as to train plant operators,” says the company.

Stand: F11.1111/5

%$Linker: