The trial section for robotised solutions and modularisation for part of an EU-wide research project, InfraROB. This aims to deliver automation technology to improve safety for workers and road users during road construction and maintenance works. Autonomous robotised machinery handles site barriers, road marking and asphalt surface repair.

STRABAG’s TPA competence centre and its partners in the EU-wide research project InfraROB has tested newly developed automation technology in practice during ongoing renovation works along the A9. The aim of the innovative solutions is to help improve the safety, efficiency and cost-effectiveness of road construction and maintenance works in the long term. For the past three years, a total of 15 companies and research institutes from eight different countries have been working on five InfraROB subprojects under the leadership of the University of Vigo, Spain.

A fully autonomous paver laid the asphalt on the 180m-long trial section near Spielfeld automatically, with implementation and logistics coordinated by a STRABAG team from Graz. Road operator and InfraROB partner ASFINAG provided the trial section. TPA and its three German partners in InfraROB Subproject 1 have thus achieved their central goal: the automatic control system that has now been developed is the missing piece for fully autonomous asphalt paving; it complements the innovative measurement and sensor technology that MOBA AG, TH Köln, TU Darmstadt and TPA had previously developed as part of the research project Robot – Road Construction 4.0 in Germany. The automation of asphalt paving could improve occupational health and safety on road construction sites in the long term, as Sebastian Czaja, Head of TPA Group PSS (Process Stability in Road Construction), points out: “In the future, paving staff will increasingly be performing the task of controller. They will be able to work at a greater distance from moving traffic, keeping them less exposed to vapours and aerosols during the paving process.”

MOBA (Mobile Automation) AG developed a special module for the autonomous control of the machinery that is connected directly to the digital CAN bus interface of the asphalt paver and feeds the machine with the target data for the paving section. Object recognition sensors and satellite navigation (GNSS) keep the paver dynamically on the right course during paving. A second innovation from InfraROB Subproject 1 is a newly developed paver attachment that was used to successfully integrate a sensor-equipped fibre optic cable (FOS cable) directly into the surface course during asphalt paving. The installed temperature and movement sensors further provide information about the load on the asphalt surface during use. In the future, this data can be used for the monitoring of road maintenance works.

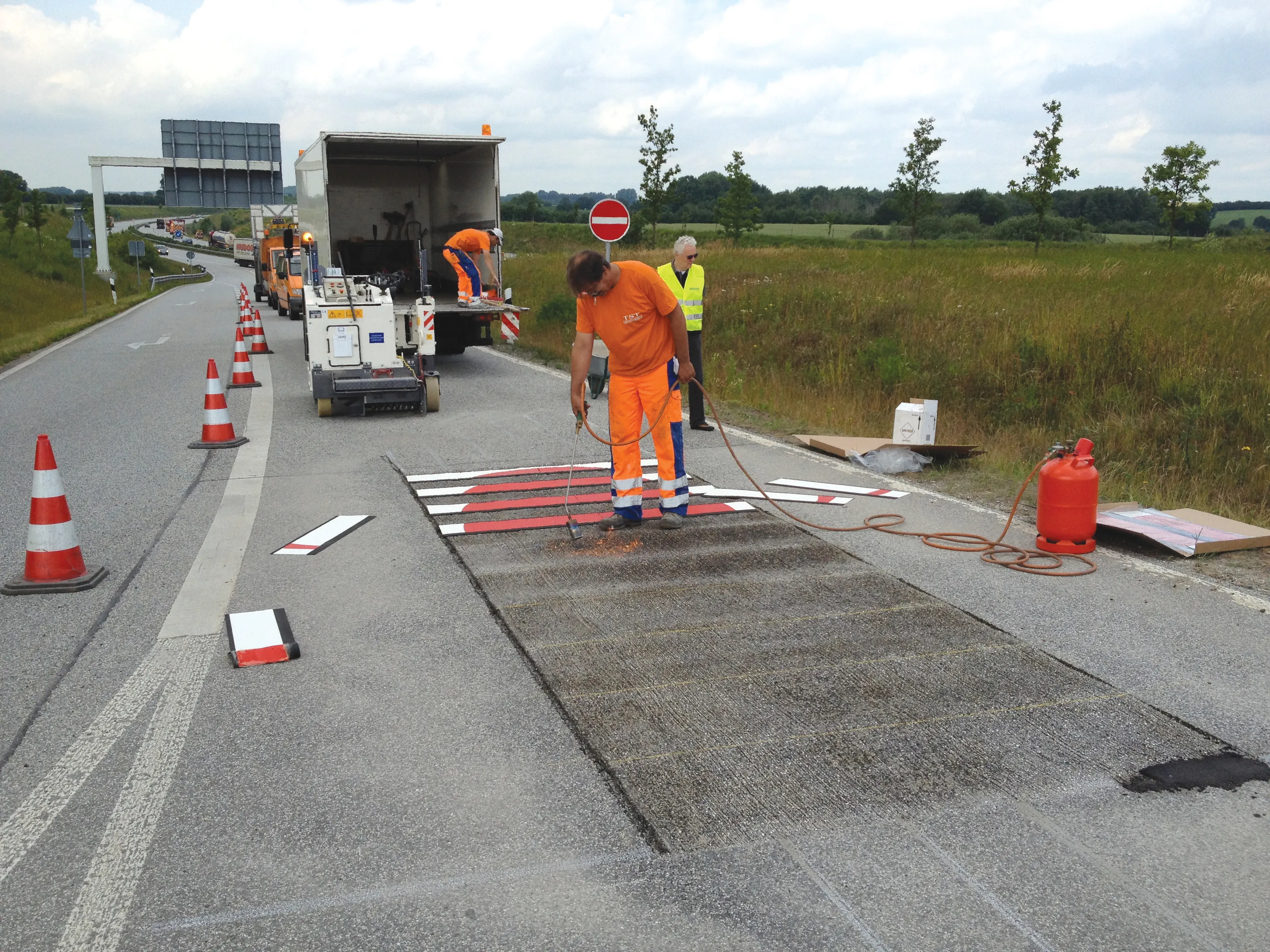

Innovative robotics from the InfraROB project could automate further work processes on road construction sites in the future, significantly reducing the risk of accidents for both workers and road users. Mobile safety cone robots, for example, were used to segment the trial section: coordinated and networked by drone (RPAS), a swarm of autonomously moving pylons (cone robots) with object recognition sensors ensured a safe distance from moving traffic (Subproject 4). Following asphalt paving, small autonomous, three-wheeled robots with paint tanks will also mark the road at the end of October.

A similarly constructed mobile robot with a 3D print head was developed in the InfraROB subproject for road maintenance: The robot will use its 3D print head to autonomously repair potholes and cracks with a cold asphalt mixture. Modular prefabrication, meanwhile, aims to improve the cost-effectiveness of road construction projects: The InfraROB partners in Subproject 3 have developed multifunctional crash barrier modules that efficiently combine crash barrier, gutter, curb and rainwater channel in an all-in-one precast concrete component. The research project also developed models for integrating InfraROB solutions into pavement maintenance systems (PMS) and traffic management systems (TMS) to improve work and traffic safety (Subproject 5).