Atlas Copco says its new Boomer E-series underground mining and tunnelling rigs, available via Atlas Copco’s own worldwide sales organisation from 2013, offers the next generation of rig control system with an improved user interface, including a new intuitive touch-screen, and user-friendly design. “With these improvements, we are confident that the new Boomer series offers one of the most powerful and productive underground mining rigs and tunnelling rigs on the market,” says, Johan Jonsson, product manag

February 13, 2013

Read time: 2 mins

“With these improvements, we are confident that the new Boomer series offers one of the most powerful and productive underground mining rigs and tunnelling rigs on the market,” says, Johan Jonsson, product manager at Atlas Copco Underground Division.

The company says that operator comfort, safety and environmental care also get priority. For example, the FOPS- certified cabins are air-conditioned and ergonomically designed featuring the latest operator seat and controls. While the large three and four-boom rigs offer a new improved and more ergonomic chair for the operator.

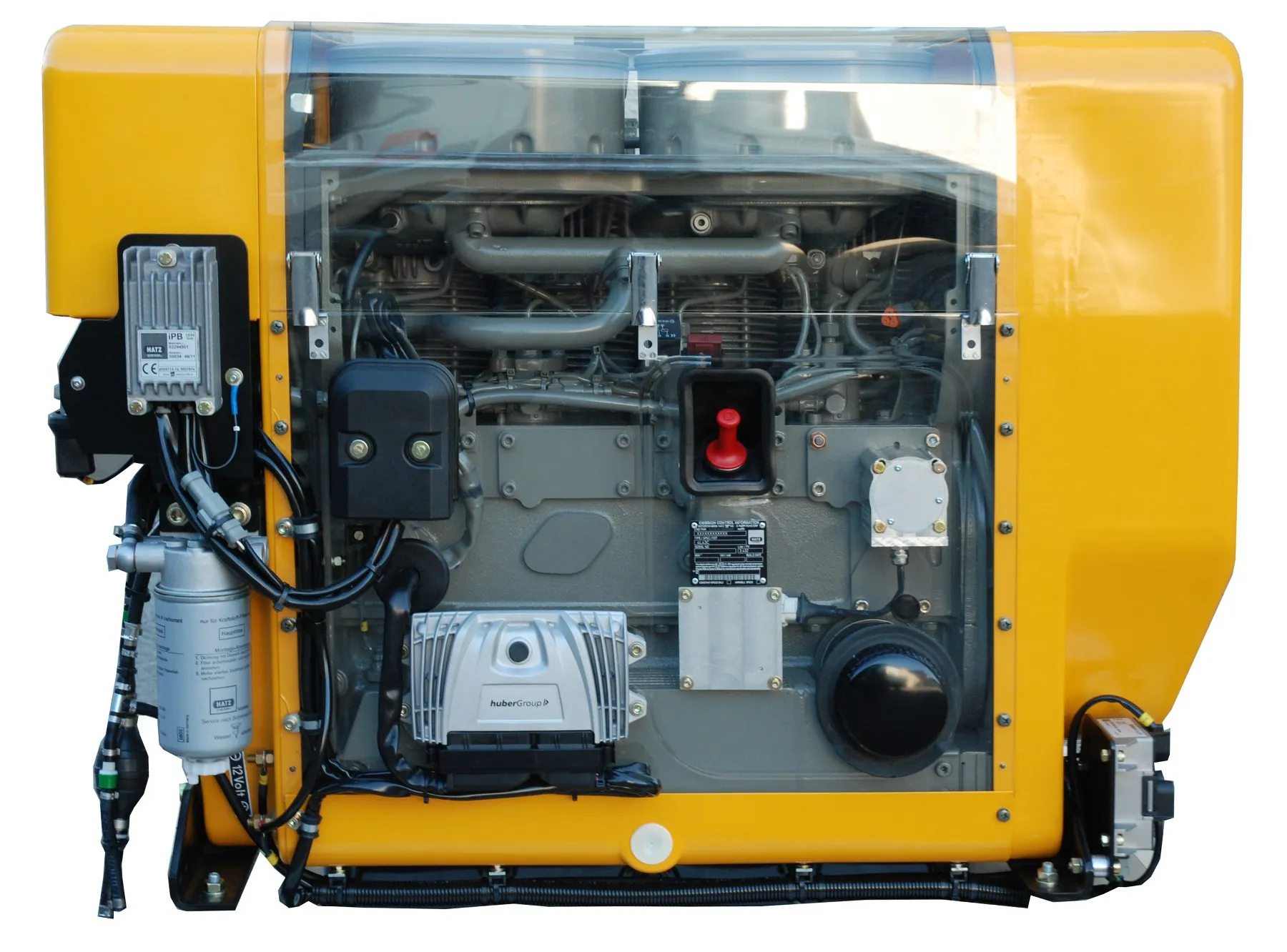

“Carbon emissions have also been reduced to a minimum as the diesel engines are needed for moving the rigs around the site while electricity is used for drilling. The rig has Stage 3B/Tier4i diesel engines as standard and biodegradable hydraulic oils are offered as options. The rig can also be equipped for dry-drilling systems,” says Atlas Copco, which has created a new underground manager system for planning and evaluation.

Stand: D1.315

%$Linker: