Atlas Copco is introducing the Edge Drill Monitor, which is designed to show what is happening at the bottom of the hole during drilling.

Information about the hammer and the bit is displayed graphically in real time, allowing the operator to optimise the penetration rate of down-the-hole (DTH) drilling, maintain the correct degree of flushing and avoid tool breakage and consequent delays.

Edge, which has been developed jointly by

“By isolating the hammer vibrations from all the other noise and analysing the frequency and amplitude of the drill bit hitting the rock thousands of feet below ground, we are able to provide the drillers with user-friendly real time information to optimize their drilling parameters,” said SPC Technology chief technology officer Ivo Henriksson. “In a recent customer evaluation programme, we reduced fuel cost per drilled footage by 10% and increased rate of penetration by 11% using the Edge.”

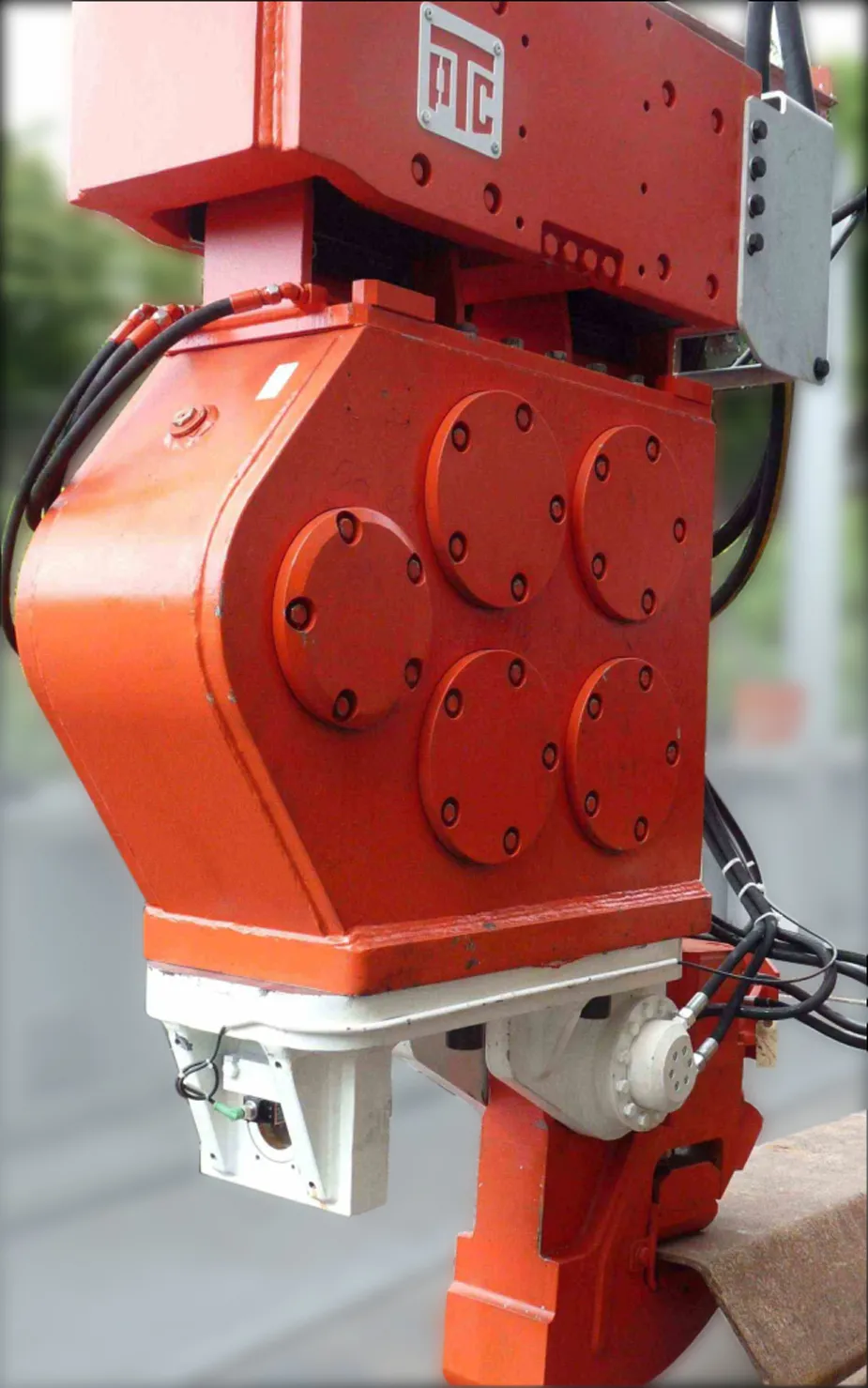

A sensor is mounted on the drill head or rotation unit, which is connected by a cable to the data capturing unit mounted on the rig. When the piston in the DTH hammer strikes the bit, it creates vibration which is captured, processed and interpreted, with the data transmitted to the PC. The PC displays this data on its 175mm screen. Any problems or unexpected changes are displayed in the graphical view in real-time with alerts when something out of the ordinary occurs. These spikes can then be interpreted, indicating scenarios such as the sudden presence of a new type of rock.

%$Linker:

Hall 5B Stand: F 027/ F015

%$Linker: