Astec Industries, which is showcasing 45 pieces of equipment at this week’s Conexpo 2014, most of it new or upgraded, has outlined its plans for the future with president and CEO Ben Brock stressing that the group is going on a major export drive.

January 6, 2017

Read time: 2 mins

Speaking at the show, Brock said that the near US$1 billion turnover group currently sells products for the infrastructure, energy and mining industries with 65% of sales in the USA and 35% from overseas.

But, “the goal is to have a 50/50 split in the next five years,” said Brock. “At present we have 60% of our sales infrastructure; 20% in mining and 20% in energy. We are hoping to see 40% in infrastructure; 30% in mining and 30% in energy. We are pushing for new business and planning to grow internationally.”

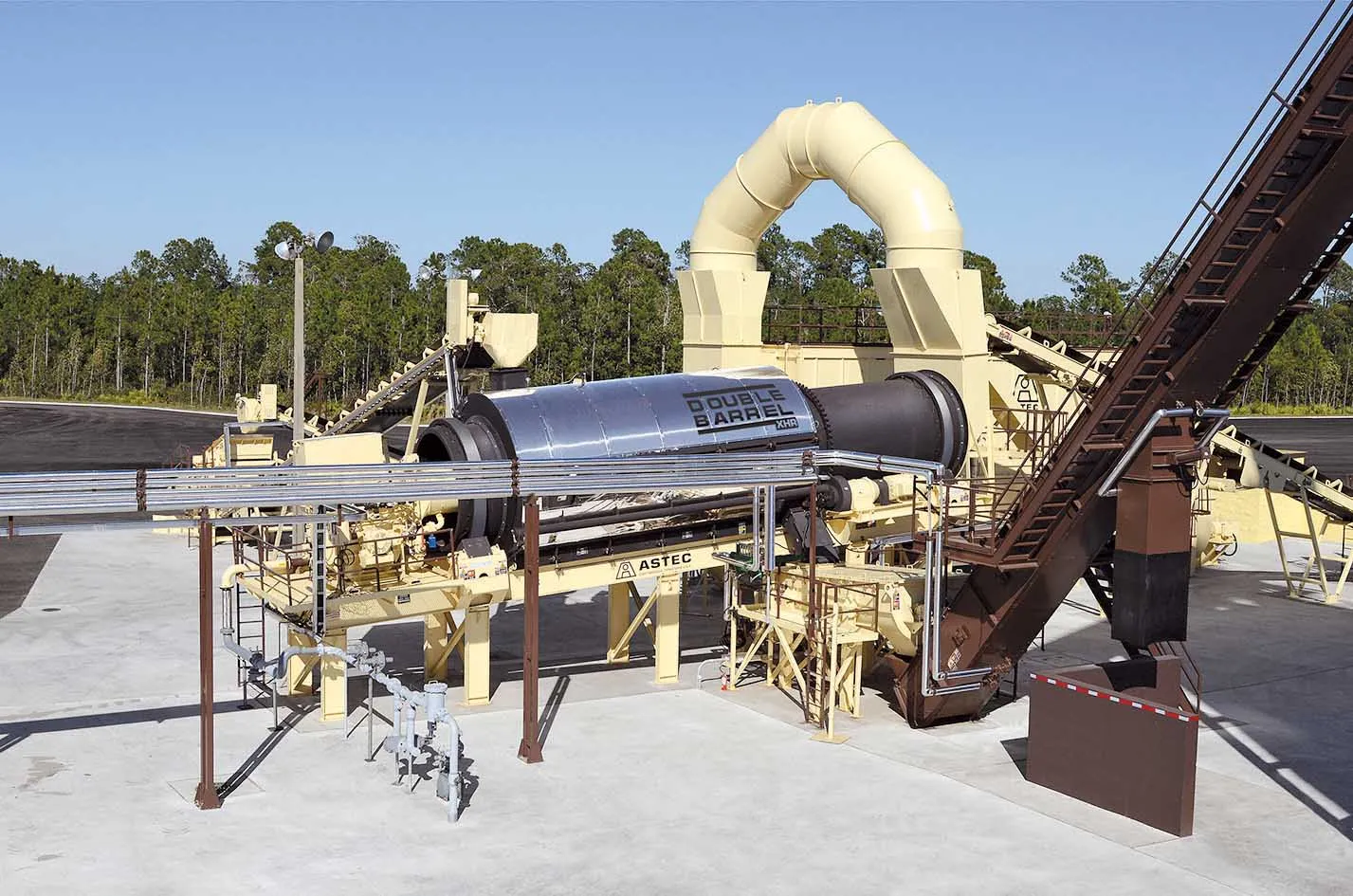

Astec Industries subsidiaries around the globe include Astec INC, Breaker Technology, Carlson Paving Products, CEI Enterprises, GEFCO, Heatec, KPI-JCI and Astec Mobile Screens, Peterson Pacific Corporation, Roadtec and Telsmith. Between them, they manufacture more than 200 products, from rock crushing and screening plants, to hot mix asphalt facilities, concrete plants, water, gas and oil drilling rigs, geothermal drills, milling machines, asphalt pavers, material transfer vehicles, and wood processing equipment.

Brock said Astec strives to be the most innovative company in the industry by offering some of the world’s most advanced, productive, durable and environmentally-friendly products.

“No other company in the world competes with Astec in all or even most of its product lines. Astec’s innovative products have led to a continuous stream of new patents. The Astec companies have become leaders in their respective markets by giving Astec customers the means to be more productive and profitable.” The group manufactures in the USA, Canada, Germany, South Africa and Australia. And there is another facility under construction in Belo Horizonte, Brazil.www.astecindustries.com