Bentley Systems is now offering a sophisticated tool that allows users to analyse the carbon profile of construction works more accurately. The new Carbon Analysis capabilities in iTwin Experience mean that construction firms can assess and reduce carbon impacts to allow a more sustainable infrastructure. The new Carbon Analysis capabilities enable infrastructure engineers to simplify carbon reporting, easily visualise embodied carbon, and rapidly explore alternatives for better designs.

“Between now and 2050, embodied carbon linked to new infrastructure, is projected to be responsible for half of the world’s carbon footprint released—even before the infrastructure is used,” added Savina Carluccio, executive director, International Coalition for Sustainable Infrastructure (ICSI). “Given its significant contribution to global emissions, the sector must act with urgency to reduce embodied carbon at scale, as part of wider decarbonisation and climate action efforts—from leveraging a highly connected and collaborative value chain to using new digital technologies that enable the selection and use of alternative, carbon-efficient materials in sustainable infrastructure designs.”

Bentley’s new Carbon Analysis capabilities integrate a user’s design data with their chosen carbon assessment tool. This enables infrastructure professionals to link carbon footprints directly to design choices and see impacts change across design iterations.

“Carbon assessments should be standard practice for global infrastructure projects, but creating carbon reports isn’t easy,” said Bradshaw. “Using Bentley’s new Carbon Analysis capabilities helps transform the tedious task of carbon reporting into a smooth, automated process—providing infrastructure professionals with greater visibility into carbon impacts and helping them design sustainable infrastructure faster and more easily.”

Traditionally, producing a carbon analysis report is manual, time consuming, and costly, with multiple steps: organising siloed data, translating the data into carbon metrics, and producing a final report. The process becomes more difficult for large, complex infrastructure projects, which typically involve diverse stakeholders, datasets, data formats, and construction materials.

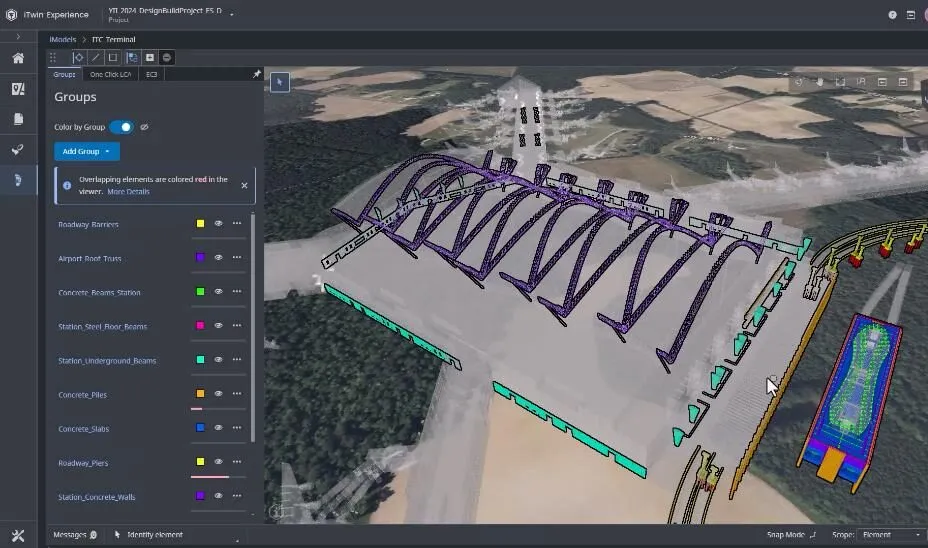

Bentley’s Carbon Analysis capabilities help overcome these challenges. The automated material quantification ingests and aggregates project and asset data, files, and models into a digital twin, for a single, simplified view. By grouping common design elements and leveraging integrated workflows, this calculates material volumes and quantities missing from design files, eliminating estimations and out-of-date spreadsheets.

Users can generate accurate cradle-to-gate embodied carbon accounting in minutes through integration with a user’s chosen carbon assessment calculator. Since data is dynamically stored, users can adjust material selections through the lifetime of a design, allowing a repeatable process.

The tool can display embodied carbon output as cloud-based heat maps in a live 3D digital twin model. This allows users to explore sustainable design and material alternatives in minutes to create higher-quality designs throughout the design and construction phase.

WSP, a global leader in environment and sustainability consulting, has been using Bentley’s new Carbon Analysis capabilities through an Early Access Program, launched in 2023.

Kelvin Saldanha, associate director, WSP, said, “In the past, there have been significant challenges when creating a carbon report for a proposed design. For example, the wide range of methodologies used to calculate embodied carbon made the process feel opaque. In addition, the process was time-consuming, as it required translating every detail into a full carbon evaluation. With Bentley’s new Carbon Analysis capabilities, our design team has better transparency to calculate, analyse, and report meaningful carbon footprint impacts within any design change—in real-time with the click of a button, which has greatly reduced feedback loops from months or weeks to days.”