Further progress has been made with regard to telematics technology for construction machines. The US Association of Equipment Manufacturers (AEM) has played a key role in securing agreements that will allow commonality in the telematics systems used by machines from different manufacturers. The Association of Equipment Management Professionals (AEMP) and the AEM have further support from the German trade association, VDBUM, for a soon-to-be-released expanded AEM/AEMP Telematics Standard.

May 21, 2014

Read time: 3 mins

Further progress has been made with regard to telematics technology for construction machines. The US 1100 Association of Equipment Manufacturers (AEM) has played a key role in securing agreements that will allow commonality in the telematics systems used by machines from different manufacturers. The 6469 Association of Equipment Management Professionals (AEMP) and the AEM have further support from the German trade association, VDBUM, for a soon-to-be-released expanded AEM/AEMP Telematics Standard.

This standard is of key importance. With this, contractors using mixed fleets of machines from different suppliers will be able to use a common telematics system for equipment management. Rather than requiring separate telematics systems for machines from each supplier, all the equipment maintenance and management data will be available through a single system. This will make major cost savings for contractors, which will be able to optimise machine maintenance and management, and without the complexity of duplicate systems operating in tandem.

VDBUM is a trade advocacy group serving the1116 European Union and global partners. The organisation specifically serves professionals in construction, environmental and mechanical engineering. VDBUM represents its members in all aspects of these industries to provide a networking outlet for professionals. Udo Kiesewalter of VDBUM Service GmbH said, “We organised our VDBUM telematics committee in April to discuss our findings after our meeting with AEM and AEMP at 3485 Conexpo-CON/AGG. During this committee meeting, we intensively discussed Version 2.0 of the telematics data standard with our end-user members and OEM´s equally.”

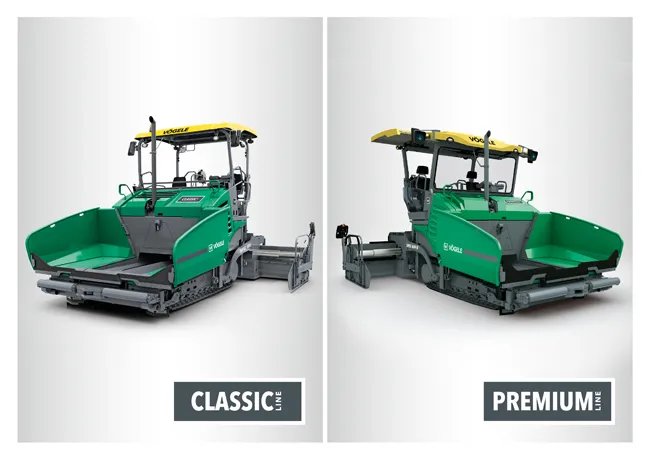

“From the OEM side,718 Liebherr, 2395 Wirtgen-1194 Vögele, 178 Caterpillar and Bauer were present. We are pleased to advise AEMP and that our committee supports the data points and the suggested frequency to be sent from the equipment asset to the full extent. Furthermore, we want to announce that Liebherr and Wirtgen-Vögele agreed to support Version 2.0 after the final end-user agreement is published by AEMP.”

Kiesewalter continued, “Our next step is to get in touch with the final version of the end-users agreement with the API for the technical implementation that will be distributed through AEMP. We want to develop a business case for telematics with our scientific partner, the University of Munich- TUM, for our end users.”

Stan Orr, CAE, president and CSO of AEMP said, “We are pleased with the commitment from VDBUM and their members to adopt the AEM/AEMP Telematics Standard for use in Europe and across all of their global operations.” He continued, “AEMP and AEM continue to work closely regarding the release of a Version 2.0 beta so that OEMs can begin the process of getting it integrated into their telemetry programs. Our goal is to have a final version available for distribution in the 4th quarter of 2014.”

This standard is of key importance. With this, contractors using mixed fleets of machines from different suppliers will be able to use a common telematics system for equipment management. Rather than requiring separate telematics systems for machines from each supplier, all the equipment maintenance and management data will be available through a single system. This will make major cost savings for contractors, which will be able to optimise machine maintenance and management, and without the complexity of duplicate systems operating in tandem.

VDBUM is a trade advocacy group serving the

“From the OEM side,

Kiesewalter continued, “Our next step is to get in touch with the final version of the end-users agreement with the API for the technical implementation that will be distributed through AEMP. We want to develop a business case for telematics with our scientific partner, the University of Munich- TUM, for our end users.”

Stan Orr, CAE, president and CSO of AEMP said, “We are pleased with the commitment from VDBUM and their members to adopt the AEM/AEMP Telematics Standard for use in Europe and across all of their global operations.” He continued, “AEMP and AEM continue to work closely regarding the release of a Version 2.0 beta so that OEMs can begin the process of getting it integrated into their telemetry programs. Our goal is to have a final version available for distribution in the 4th quarter of 2014.”