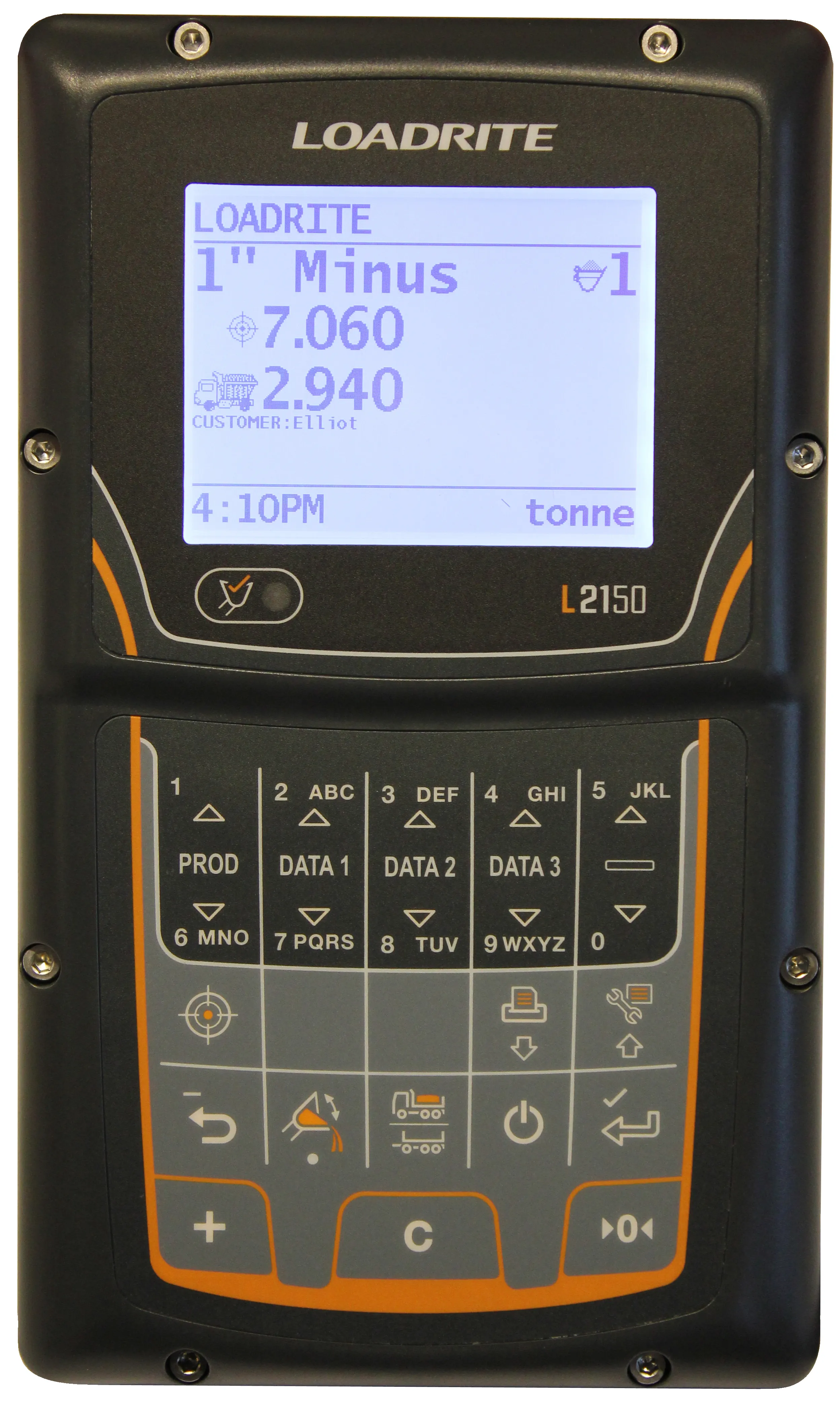

The Loadrite L2150 wheeled loader bucket weighing system is said to offer increased accuracy and reliability. The system is said to ensure haul trucks can be loaded properly, improving overall productivity by ensuring operational efficiency. Using this weighing system trucks are neither under-loaded nor over-loaded, with the ensuing associated productivity losses and excess machine wear problems respectively, all but eliminated. Aimed at use in large quarry operations the new Loadrite L2150 unit is said to

January 6, 2017

Read time: 2 mins

The 5004 Loadrite L2150 wheeled loader bucket weighing system is said to offer increased accuracy and reliability. The system is said to ensure haul trucks can be loaded properly, improving overall productivity by ensuring operational efficiency. Using this weighing system trucks are neither under-loaded nor over-loaded, with the ensuing associated productivity losses and excess machine wear problems respectively, all but eliminated. Aimed at use in large quarry operations the new Loadrite L2150 unit is said to be tough and dependable and provides extensive data capture capabilities. The firm does also offer more basic bucket weighing units for smaller wheeled loaders. In addition, the company claims its X2350 bucket weighing system for excavators can provide accurate measurements and without slowing operations. The company also supplies a sophisticated conveyor load weighing system that can help optimise tonnes/hour and maximise utilisation and uptime. The conveyor system ensures optimum loads on conveyors can be maintained, maximising productivity through a plant and also reducing the risk of premature component wear, potential failures and additional downtime for repairs.

Stand: C2.121

%$Linker: