Boasting all the power of their non-hybrid counterparts, the 38-ton class EC380E Hybrid has the added benefit of being a more environmentally respectful choice, offering a reduction in CO2 emissions of up to 15%. Featuring the unique hydraulic hybrid Volvo technology, this hard worker is the perfect option for customers looking to save fuel, lower emissions and boost the profitability of their operations.

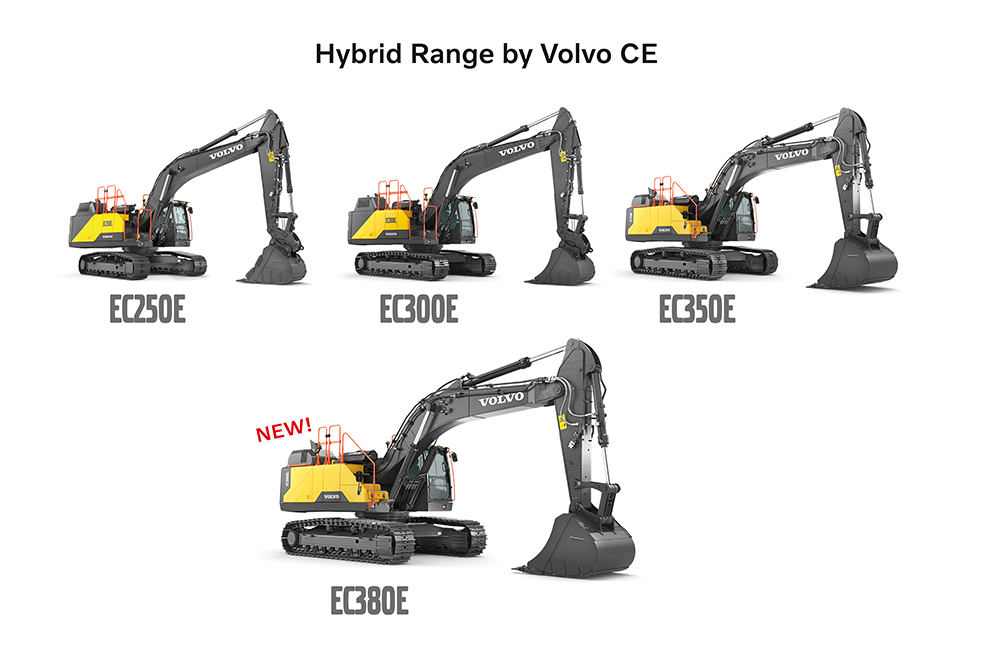

Now the largest in the line up of four hybrid excavators, this new arrival is built on a solid foundation. The unveiling of the revolutionary EC300E Hybrid back in 2019, hailed at the time for pushing the boundaries of efficiency while still maintaining power and productivity, was only just scratching the surface of what Volvo CE hybrid technology could achieve. Since its launch, it has proven itself as a reliable partner on the jobsite, been recently upgraded with an all-new powertrain and has seen two new hybrid machines join the family – the 25-ton class EC250E Hybrid and 35-ton class EC350E Hybrid.

Now the largest in the line up of four hybrid excavators, this new arrival is built on a solid foundation. The unveiling of the revolutionary EC300E Hybrid back in 2019, hailed at the time for pushing the boundaries of efficiency while still maintaining power and productivity, was only just scratching the surface of what Volvo CE hybrid technology could achieve. Since its launch, it has proven itself as a reliable partner on the jobsite, been recently upgraded with an all-new powertrain and has seen two new hybrid machines join the family – the 25-ton class EC250E Hybrid and 35-ton class EC350E Hybrid.

Kangwook Kim, Global Product Manager, says: “We knew when we launched the EC300E Hybrid two years ago that we were only at the beginning of our hybrid journey. Our unique hybrid hydraulic technology has proved it has the potential to work across a range of excavators, no matter the size, and we will continue to build on our offering in order to provide the most efficient, flexible and environmentally responsible solutions for our customers.”

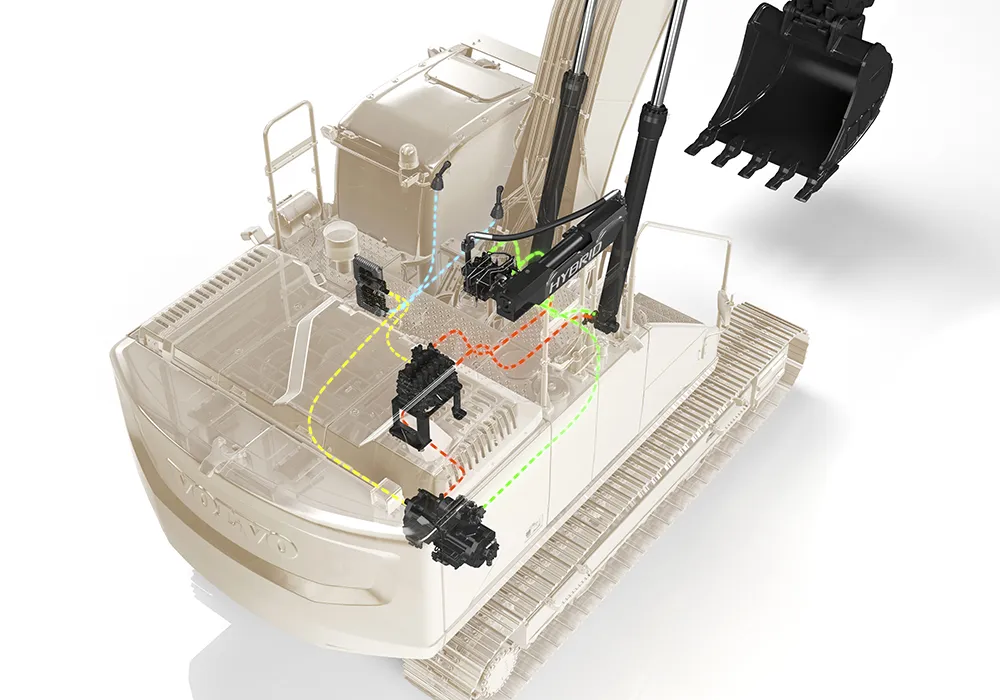

Every machine in the hybrid range uses Volvo’s unique hydraulic-hybrid technology that harvests ‘free’ energy generated by the down motion of the excavator’s boom. The powerful and regular boom-down motions charge a hydraulic accumulator, which then stores and delivers energy, when needed, to drive the hydraulic assist motor that helps power the engine system. The Hybrid models involve no compromise in ability, with these excavators offering the same levels of controllability and performance as non-hybrid machines.

Every machine in the hybrid range uses Volvo’s unique hydraulic-hybrid technology that harvests ‘free’ energy generated by the down motion of the excavator’s boom. The powerful and regular boom-down motions charge a hydraulic accumulator, which then stores and delivers energy, when needed, to drive the hydraulic assist motor that helps power the engine system. The Hybrid models involve no compromise in ability, with these excavators offering the same levels of controllability and performance as non-hybrid machines.

The biggest difference between Volvo CE’s hybrid concept and those of its competitors is that it uses the up and down motion of the boom to capture free energy. Other systems typically use the swing motion and capture energy that way. With Volvo CE, customers are able to capture the energy of a typical loading cycle, which is really how the system is able to optimize workflow.

Rapid payback in dig and dump applications

All this simple and uncomplicated cleverness takes load off the engine, and in the process delivers between 10-12% lower fuel consumption, up to 12% less CO2 emissions – and all with no loss of performance. When used in production ‘dig and dump’ applications (esp. those with a 90 degree swing) the payback of this simple approach can be a little more than a year. The machine provides the same levels of controllability and performance you would expect from the equivalent conventional machine, including the ability to work in ECO Mode and Hybrid Mode simultaneously, and up to 17% fuel efficiency improvement dependent on application.

All this simple and uncomplicated cleverness takes load off the engine, and in the process delivers between 10-12% lower fuel consumption, up to 12% less CO2 emissions – and all with no loss of performance. When used in production ‘dig and dump’ applications (esp. those with a 90 degree swing) the payback of this simple approach can be a little more than a year. The machine provides the same levels of controllability and performance you would expect from the equivalent conventional machine, including the ability to work in ECO Mode and Hybrid Mode simultaneously, and up to 17% fuel efficiency improvement dependent on application.

The cost-effective and reliable hybrid solution is easy to maintain and consists of just a handful of add-on components, meaning no disruption or complication to how the high performing 38-ton class excavators work.

Superior performance

The latest generation, Volvo engine Tier4f emissions certified diesel engine fully meets the demands of the latest, emissions regulations. Featuring Volvo Advanced Combustion Technology (V-ACT), it is designed to deliver superior performance and fuel efficiency. The engine uses precise, high pressure fuel injectors, turbo charger and air-to-air intercooler, and electronic engine controls to optimize machine performance. With the automatic idling system, engine speed is moved to idle when the levers and pedals are not activated resulting in less fuel consumption and low cab noise levels.

The machines’ high-capacity electrical systems are well protected. Waterproof doublelock harness plugs are used to secure corrosion-free connections. The main relays and solenoid valves are shielded to prevent damage. The master switch is standard. Contronics provides advanced monitoring of machine functions and important diagnostic information.

The machines’ high-capacity electrical systems are well protected. Waterproof doublelock harness plugs are used to secure corrosion-free connections. The main relays and solenoid valves are shielded to prevent damage. The master switch is standard. Contronics provides advanced monitoring of machine functions and important diagnostic information.

Operator comfort and safety

The operator’s cab has easy access via a wide door opening. The cab is supported on hydraulic dampening mounts to reduce shock and vibration levels. These along with sound absorbing lining provide low noise levels. The cab has excellent all-round visibility. The front windshield can easily slide up into the ceiling, and the lower front glass can be removed and stored in the side door. With an integrated air conditioning and heating system, the pressurized and filtered cab air is supplied by an automatically controlled fan and the air is distributed throughout the cab from 14 vents. The ergonomic adjustable seat and joystick console move independently to accommodate the operator and has 12 different adjustments plus a seat belt for the operator’s comfort and safety.

With this latest machine to the hybrid range, Volvo CE is committed to a more sustainable operation and a reduced environmental footprint.

Key Specifications of the Hybrid Range

|

|

|

EC250E Hybrid |

EC300E Hybrid |

EC350E Hybrid |

EC380E Hybrid |

|

Operating weight |

kg |

27 150 – 28 310 |

30 990 – 32 720 |

36 260 – 38 290 |

37 800 - 43 000 |

|

lb |

60,032 – 62,413 |

68,608 – 72,135 |

|

83,335 - 94,799 |

|

|

Gross power |

kW |

168 |

189 |

220 |

230 |

|

hp |

225 |

253 |

|

308 |

|

|

. . . at engine speed |

rpm |

1 600 |

1 600 |

1 600 |

1 700 |

|

Bucket capacity |

m3 |

0.56 – 1.76 |

0.52 – 2.06 |

0.87 – 2.33 |

0.83 - 2.53 |

|

yd3 |

1.0 – 2.0 |

1.0 – 3.0 |

|

1.09 - 3.31 |

|

|

Lifting capacity, along undercarriage |

kg |

10 050 |

11 460 |

13 470 |

15 940 |

|

lb |

22,156 |

25,264 |

|

35,142 |

|

|

. . . at reach / height |

m |

6.0 / 1.5 |

6.0 / 1.5 |

6.0 / 1.5 |

6.0 / 1.5 |

|

ft |

19.7 / 4.9 |

19.7 / 4.9 |

19.7 / 4.9 |

19.7 / 4.9 |

|

|

Max. digging reach |

mm |

10 340 |

10 710 |

11 123 |

10 545 |

|

ft - in |

33’11” |

35’2” |

|

34'7" |

|

|

Max. digging depth |

mm |

7 060 |

7 340 |

7 490 |

6 785 |

|

ft - in |

23’2” |

24’1” |

|

22'3" |

|

|

Breakout force, SAE J1179 (Normal) |

kN |

145 |

165 |

117 |

198 |

|

lbf |

32,597 |

37,094 |

|

44,512 |

|

|

Breakout force, SAE J1179 (Boost) |

kN |

157 |

179 |

192 |

215 |

|

lbf |

35,295 |

40,241 |

|

48,334 |

|

|

Tear out force, SAE J1179 (Normal) |

kN |

114 |

133 |

201 |

196 |

|

lbf |

25,628 |

29,900 |

|

- |

|

|

Tear out force, SAE J1179 (Boost) |

kN |

124 |

144 |

219 |

213 |

|

lbf |

27,876 |

32,373 |

|

47,862 |

|

|

Overall width |

mm |

3 190 |

3 190 |

3 190 |

3 540 |

|

ft - in |

10’6” |

10’6” |

|

11'7" |

|

|

Tail swing radius |

mm |

3 075 |

3 120 |

3 600 |

3 600 |

|

ft - in |

10’1” |

10’3” |

|

11'10" |

Content produced in association with Volvo CE