The EC260 and EC300 excavators are the latest models to be announced this year in Volvo CE’s new generation excavator launches. All boast increased productivity, enhanced safety and a host of cab upgrades. While the EC300 is a new generation machine, the all-new EC260 replaces the EC250 in Volvo’s line-up. These modern marvels offer unmatched versatility across the most demanding applications, from site preparation and road building to agriculture and utilities – delivering the best possible performance to meet customers’ changing needs.

Optimized productivity

Already recognized as the best in the industry, Volvo’s excavator cabs have just got even better – with several updates designed to improve operator comfort, productivity and safety. These include an updated seat, a larger side mirror and additional lights, sunscreens and storage areas, as well as a keyless start with the ability to store multiple operator preference settings.

An improved human-machine interface (HMI) and a larger, higher-resolution Co-Pilot display provide a much more modern environment suited for the demands of the job. In all, these features allow for easier, faster and smoother operations, with less fatigue – boosting overall operator performance.

Safely in control

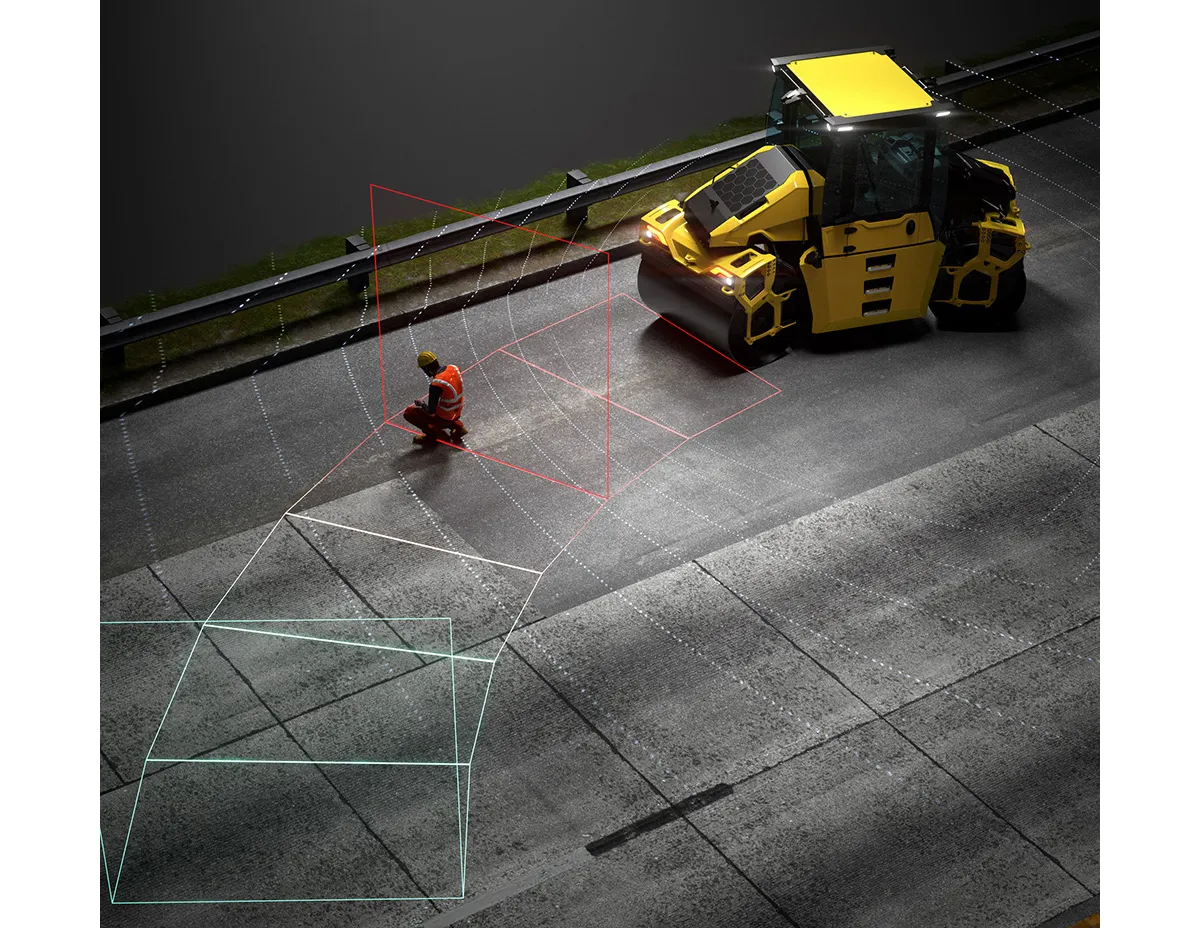

The Volvo Smart View with Obstacle Detection, with its HD camera and new radar detection system, gives operators 360 degree visibility of the machine’s surroundings and the ability to distinguish between objects and humans.

Safe access, operation and servicing are also ensured thanks to existing features such as the new 3 point access to the cab from the right side of the machine and the orange seat belt with locking alarm.

Easier maintenance

Longer service intervals, together with improved serviceability with more ground level access points, grouped filters and lubrication points, not only ensure a lower total cost of ownership but make maintenance faster and easier than ever before.

Advanced technology

The innovative electro-hydraulic system, integrated already as part of the previous model series, helps to dramatically reduce fuel consumption and lower operating costs, by regulating engine speed and hydraulic flow rate based on the task at hand. Thanks to its intelligent use of electronic sensors to monitor operator movements, the result is smooth and precise control for the most accurate digging and loading.

The machines also benefit from proven digital solutions such as Volvo Active Control, part of the suite of Dig Assist tools, to speed up operations, with faster cycle times and reduced operating costs. The machine control system, together with an advanced electric joystick, automate boom and bucket movement for precision and efficiency. Additional support

The must-have Dig Assist tool ensures unrivalled machine guidance and control technology, enabling operators to work with the highest levels of precision and accuracy. While the addition of On-Board Weighing provides real-time insights into the bucket’s load, helping to eliminate overloading, underloading, reweighing and waiting time. The EC260 and EC300 excavators become even more versatile when matched with Volvo attachments to bring maximum productivity and uptime.

The new models will be available in Europe and North America over the coming months.

Content produced in association with Volvo CE

Key specifications:

| EC260 | EC300 |

Operating weight | 28 460 - 34 320 kg | 29 700 - 38 800 kg |

Gross power | 168 kW | 189 kW |

. . . at engine speed | 1,350 rpm | 1,400 rpm |

Bucket capacity | 0.46 - 1.76 m3 | 0.52 – 2.06 m3 |

Lifting capacity, along undercarriage | 9,220 kg | 9,140 kg |

. . . at reach / height | 4.5 / 4.5 m | 4.5 / 6.0 m |

Max. digging reach | 9,960 mm | 10,185 mm |

Max. digging depth | 6,590 mm | 6,845 mm |

Breakout force, SAE J1179 (Normal) | 145 kN | 164 kN |

Breakout force, SAE J1179 (Boost) | 157 kN | 179 kN |

Tear out force, SAE J1179 (Normal) | 132 kN | 158 kN |

Tear out force, SAE J1179 (Boost) | 143 kN | 172 kN |

Overall width | 3,190 mm | 3,190 mm |

Tail swing radius | 3,080 mm | 3,125 mm |

Content produced in association with Volvo CE