The TSX model is designed to maximise RAP use as well as offering mobility, while the latest Explorer model is designed with a focus on ease of mobility and commissioning but can also use RAP in its feed.

MARINI-ERMONT’s TSX plant benefits from a new, patented technology that allows up to 70% RAP in the feed to produce mix quickly and simply. The TSX follows on from the innovative TRX plant from the firm, which is able to use up to 100% RAP in the feed.

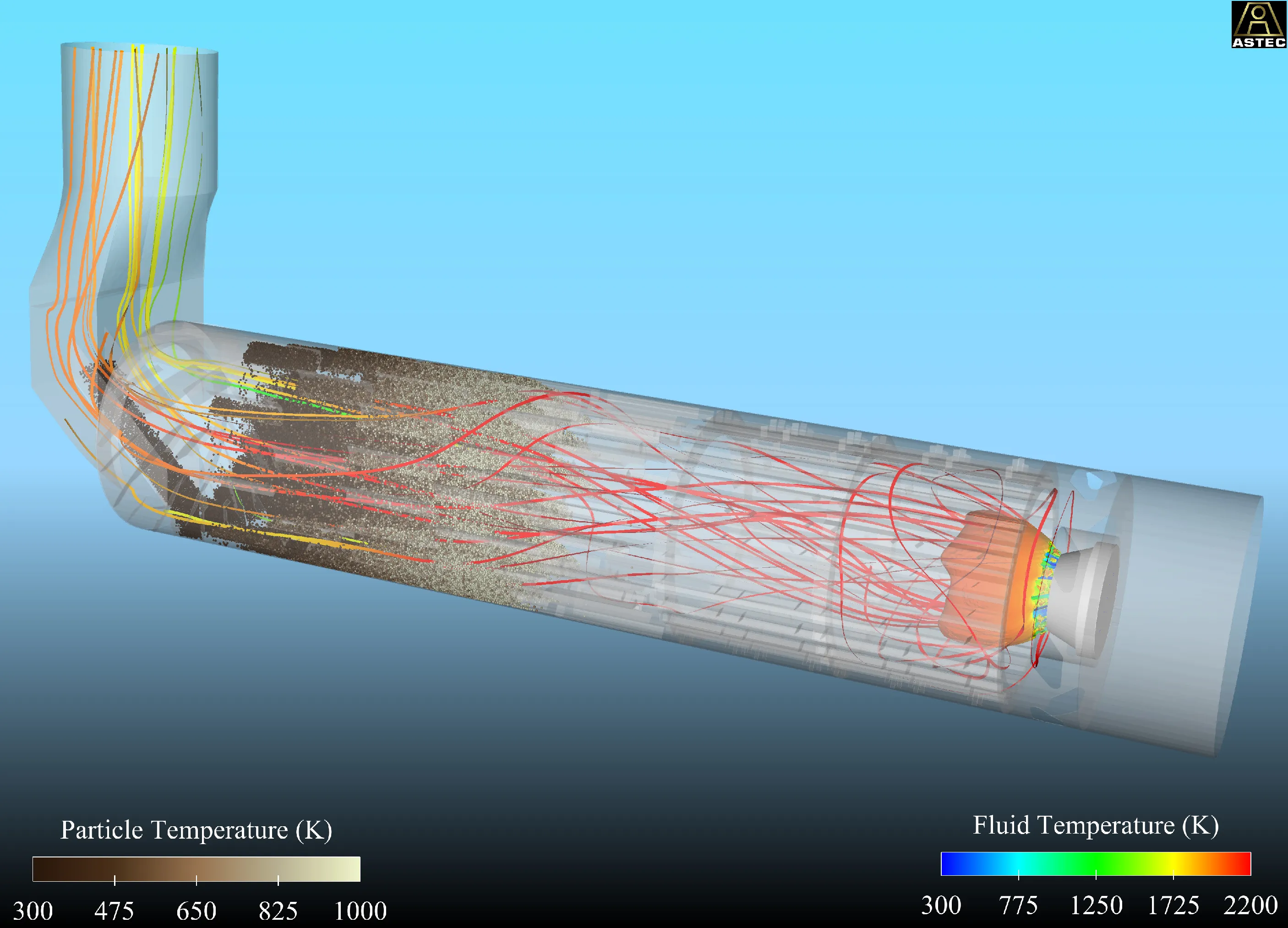

The innovative design used in the TSX plant uses a parallel flow dryer drum that comprises three distinct zones, mounted in series with a synchronised twin-shaft mixer. The first of the three zones in the drum is the combustion zone. In this area, the burner flame generates hot gases to dry and heat the aggregates and RAP. In a second zone, the hot gases from the first zone exchange with the aggregates at first so as to dry and heat them, as well as to store extra energy in the aggregates and to lower the gas temperatures. This second zone also acts as a thermal shield to prevent any flame radiation into the third zone, where the RAP is fed into the drum via a recycling ring. The RAP is dried in this third zone using the DuoTHERM heat exchange process. Heat is exchanged between the RAP and the slightly overheated aggregates. At the same time, the gases are at moderate temperatures in this zone having previously exchanged heat with the aggregates. As this is a long zone in the drum, there is time for the RAP binder to migrate homogeneously over all of the aggregates.

On leaving the drum, the mix is homogeneous in grain size and temperature and is then fed into the synchronised twin shaft mixer where it is mixed with the imported binder and a possible rejuvenator. A long mixing time ensures the second phase of completion of the remobilisation of the binder.

This new patented technology makes it possible to produce high-quality HMA while using RAP, by never exposing the binder to the radiation of a flame or to excessive temperatures throughout the heating and mixing process.

MARINI-ERMONT claims that the TSX technology is novel as it can recycle up to 70% of RAP without compromising on asphalt quality, while using just one drum and one burner. This technology based on the DuoTHERM heat exchange process combines versatility and ease of use. This new plant allows users to vary the recycling rate according to the needs of the formulations without any specific modification to the system.

There are three TSX models, the TSX 22, TSX 26 and TSX 28 with output ranges of 120-270tonnes/hour, 160-380tonnes/hour and 200-450tonnes/hour respectively depending on the mix types being produced.

The Explorer plant comes in modular format, with its components all slotted inside standard shipping containers, minimising the cost of transport by road, rail or sea compared to other units. The firm says that the Explorer benefits from the firm’s latest Softmix automation control system, allowing high-quality hot mix production to meet tight specification requirements.

The design also has a very low energy consumption according to the firm, due to the use of a high-tech atomising burner that is assisted by compressed air, while short, heat-insulated circuits allow energy consumption to be optimised.

A high RAP recycling rate of up to 50% can also be achieved, without compromising mix quality. With its various features and benefits, the Explorer offers one of the highest returns on investment of any asphalt plant due to its performance, ease of transport and adaptability according to MARINI-ERMONT. Versatility is further optimised as the plant can be installed onsite without requiring a crane or a pre-prepared pad area.