Trimble has established high level partnerships with key construction machinery manufacturers Caterpillar and John Deere.

Caterpillar and Trimble are extending their long-standing technology joint venture. The agreement includes expanded distribution of grade control solutions in construction to accelerate innovation and customer adoption.

Meanwhile, Trimble has set up a new strategic relationship with John Deere that will speed the adoption of grade control technology for construction.

Since 2002, the Caterpillar Trimble Control Technologies (CTCT) joint venture has provided construction with grade control solutions, boosting jobsite safety and productivity.

The renewed agreement will increase industry reach and provide customers broader availability of interoperable grade control solutions via a flexible platform for use by Caterpillar, Trimble and other technology providers and equipment manufacturers. With a strengthened partnership, this agreement enables both Trimble and Caterpillar to increase innovation and differentiation, develop new offerings and pursue new industry and geographic opportunities.

For Caterpillar customers, there are new factory-fit grade options through Caterpillar, while Cat Grade 3D Ready options allow upgrading at any point within the machine lifecycle. There will be expanded aftermarket and digital offerings directly through Cat dealers. Meanwhile, Trimble customers also benefit from broader availability with continued mixed-fleet support from trusted SITECH dealers, expanded distribution networks to meet the needs of mixed fleet customers. In addition, streamlined access to grade control through Trimble Construction One suite of digital solutions further extends Trimble’s construction technology ecosystem

Similarly, the availability of the Trimble Earthworks Grade Control technology integrated with the John Deere SmartGrade platform will make it easier for John Deere customers to leverage the full benefits of machine control for increased productivity, efficiency and better decision making.

For more than a decade, John Deere has offered a Trimble Ready option on select machines to simplify installation in the aftermarket. With this expanded relationship, select John Deere machines equipped with SmartGrade technology will make Trimble Earthworks available direct from the factory or as a field upgrade. This integration will allow machines equipped with SmartGrade to fit seamlessly into the Trimble technology ecosystem simplifying the ways to connect the office to the field and leverage jobsite data.

This collaboration will boost jobsite safety and efficiency and promote the adoption of machine control technology in construction. To make adoption seamless for the customer, various purchasing options will be available in the future for John Deere SmartGrade with Trimble Earthworks, including factory direct or field installations, and as part of the Trimble Construction One suite of digital solutions.

Integrating Trimble Earthworks will provide John Deere customers greater access to Trimble’s construction technology ecosystem. This allows the customer to elevate operations by connecting and managing data throughout the design-build-operate lifecycle of construction projects.

Meanwhile, developing machine control solutions for the compact equipment market is a market the connected construction technology suppliers have yet to cultivate. According to Steve Di Benedetto at Trimble, “There is a tremendous potential for Trimble.”

Democratisation of machine control technology means that systems are becoming available for use with compact equipment and these packages will be of key interest for smaller firms looking to boost working efficiency. The latest development is a new package for use with skid steer loaders and compact tracked loaders.

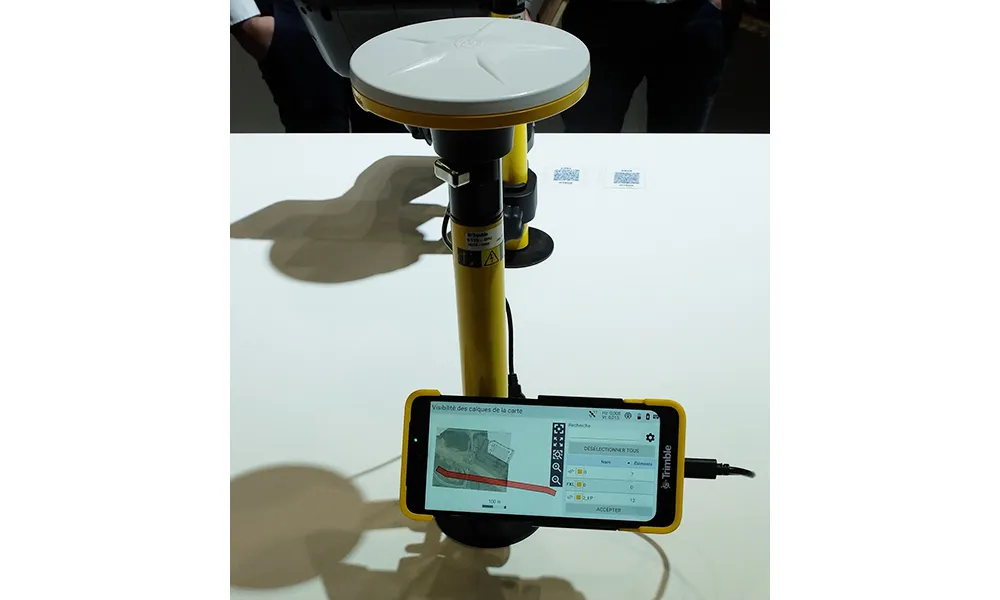

A key feature of this new system is the fact that the customer can use a conventional smartphone or tablet. It is this detail that makes the system so much easier to use given that customers will already be familiar with a wide range of apps on their phones. Di Benedetto commented, “They’re already doing so much on the phone. They’re doing it in the cloud so they don’t have to install software. It’s in a language and a user interface that they’re already familiar with.”

According to Trimble, the addition of Siteworks Machine Guidance for compact track loaders further boosts versatility, providing an all-in-one solution for layout, grading and levelling. Trimble says that users can also move the system between multiple machines and jobsites, and to utilise their existing technology easily, with the addition of a simple-to-install machine kit and the Siteworks software module.