On the almost 70 m-tall Aftetal Bridge west of Bad Wünnenberg, the contractor faced specific weather conditions and stringent quality requirements. As a result, Franz Trippe GmbH chose Vögele machines and digital solutions: WITOS Paving Docu, including RoadScan and Jobsite Temp, enabled the team to record paver, paving and temperature data on site via smartphone and to monitor them in real time.

A project due to be completed in Spring 2022 is building a bypass around Bad Wünnenberg, in Westphalia, to relieve traffic congestion. The new B480 is part of a large-scale traffic corridor to make the Hochsauerland region more accessible. The most demanding section of this large-scale project, the Aftetal Bridge which is almost 70 m tall and 785 m long, presented a few road construction challenges, too: its height and exposed position in the terrain means that even in good weather, there is always a wind blowing which rapidly cools the paving mix. The client, Landesbetrieb Straßenbau Nordrhein-Westfalen (Straßen.NRW), was simultaneously demanding the highest possible standards of quality for the paving.

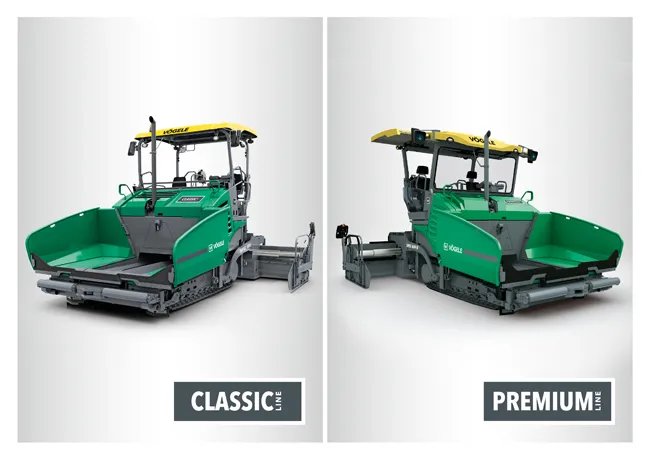

Applications from the machine manufacturer

The contractor, Franz Trippe GmbH from Schmallenberg in the Sauerland region, approached the project with digital support. “We have been giving a high priority to digital processes for years,” says Managing Director Stefan Trippe. “For example, we work with our own cloud solutions and rely on 3D technology in a lot of our machines to make us even more efficient and accurate and to meet increasing demands on quality and costs.” In order to keep an eye on temperatures continuously when paving the B480n and to record job site processes accurately, the company chose the relevant solutions from road paver manufacturer Vögele: WITOS Paving Docu, including the RoadScan non-contact temperature measuring system and the new Jobsite Temp app. WITOS Paving Docu allows paving and machine data to be recorded via smartphone and analysed at the end of the day. In combination with RoadScan, contractors can also record and analyse paving temperatures. During paving, current temperature data can be viewed via the display of the paver operator’s console. The new Jobsite Temp app furthermore enables the foreman and other users to access temperature data and supplementary data via smartphone in real time: among other things, it shows current pave speeds, screed width, the positioning of the paver and the position of the mix transfer point including delivery note information.

All data visible with a smartphone

“By combining WITOS Paving Docu with RoadScan, we created the conditions on the one hand for checking paving temperature continuously under the difficult weather conditions and on the other, for meeting the quality and documentation requirements,” says Stefan Trippe. Amongst other things, the contractor paved a 3.5 cm-thick surface course up to 12 m wide on two sections, measuring some 2 km each, ahead of and on the Aftetal Bridge. The team also counted on Vögele machines: a paver of the SUPER 1800-3i type worked in two strips in combination with the AB 500 TP1 Extending Screed. In the high compaction variant with tamper and pressure bar, the screed ensured a high level of precompaction which reduced the number of roller passes subsequently required. The contractor furthermore made use of a latest-generation PowerFeeder to prevent paver interruptions and to transfer the mix rapidly and smoothly: the high-performance MT 3000-3i Offset PowerFeeder. “The machines enabled us to facilitate smooth processes, stop the mix cooling down and create conditions for a high standard of paving quality,” says Stefan Trippe. “In combination with WITOS Paving Docu and Jobsite Temp, we were also able to view all the relevant data on a smartphone at all times, determine the ideal compaction window, take counter-measures if necessary and record all the processes associated with paving accurately, quickly and paper-free.”

Simple to use, a reliable check

The technical prerequisite for WITOS Paving Docu is a telematics module fitted in the paver; Jobsite Temp requires RoadScan as well. The core of this system is the infrared camera including GPS receiver fitted to the paver’s hardtop. Paving supervisor Dennis Voss was then able to launch both apps on his smartphone on the job site and link to the paver via QR code. The app and the paver are networked by WiFi, allowing information to be exchanged between the RoadScan temperature measuring system and a smartphone even when there is no mobile phone signal. “This is especially practical on jobsites like this which are remote and without the corresponding network coverage,” says Dennis Voss. He uses WITOS Paving Docu to record all paver and paving data such as pave widths, pave speeds and effective pave times. The application was also able to calculate continuously paving surface areas, quantities and densities. It was perfectly simple for Voss and his team to scan in delivery notes via QR code and view them at any time. “Compared to manual recording, of course, this saved us a great deal of time - and simultaneously, we could keep an eye on all the delivery notes and tonnages at all times,” says Dennis Voss. Voss and his team also used Jobsite Temp to monitor paving temperatures in real time. “The wind meant that we had to monitor temperatures continuously. The app helped raise the necessary awareness amongst all staff, including the roller operators, and determine the ideal paving and compaction window.” Roller operators were likewise able to use the app to view their own position and distance from the paver and to define exclusion zones.

Perfectly equipped – even for reduced-temperature asphalts

This enabled the team to coordinate paving and compaction perfectly to achieve a high standard of paving quality. WITOS Paving Docu allowed paving supervisor Dennis Voss to record all jobsite data transparently and seamlessly without having to spend a lot of time on Excel lists or tablet solutions as he used to. He was impressed by the combination of ease of use, reliability and variety of information. “WITOS Paving Docu and Jobsite Temp are structured very intuitively, concentrate on the relevant data and require almost no prior knowledge.” The company intends using both applications for almost all its projects in future, especially where quality requirements are particularly stringent: when constructing major roads or industrial areas, for example. “The subject of reduced-temperature asphalt, for which the paving and compaction window is even tighter than for conventional high-temperature asphalt, is becoming more and more important,” says Stefan Trippe. “WITOS Paving Docu, RoadScan and the new Jobsite Temp app equip us perfectly for that.”

To find out more, click here.

Content produced in association with Wirtgen Group