A particular manifestation of the problem is known as the urban heat island (UHI) effect. UHIs manifest as the temperature rise in built-up urban areas relative to the surrounding rural countryside, largely because of the relatively greater proportion of incident solar energy that is absorbed and stored by man-made materials. The direct impact of UHI can be significant on both daytime and night-time temperatures, and the indirect impacts include increased air conditioning loads, deteriorated air and water quality, and reduced pavement lifetimes. As temperature extremes become more frequent, future pavement properties will fall outside the current design envelope. Mitigation strategies can be roughly lumped into two categories: increased vegetation (trees, landscaping, and green spaces) and changes to building practices including, alternative pavements and paved surfaces design with modified thermal properties and a longer life span.

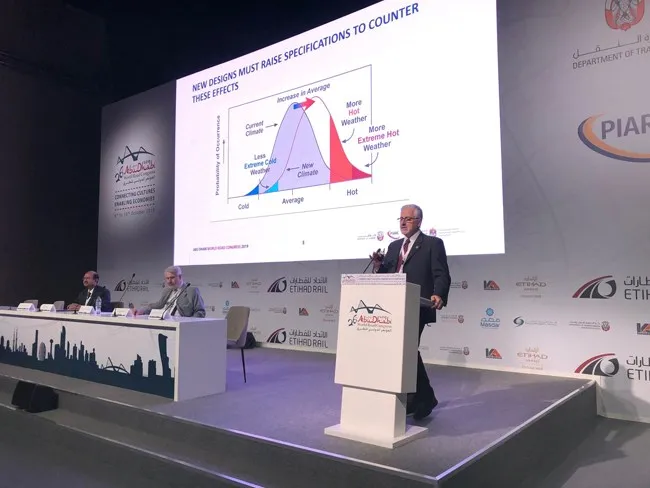

Against this backdrop, the International Road Federation sponsored a foresight session on sustainable pavements during the recent PIARC World Road Congress in Abu Dhabi. The aim of the session was to present a comparative benchmark of the state of readiness of the most promising pavement technologies, and endeavour to achieve a high-level consensus on the political and financing framework required to operate the transition from pilots today, to large-scale deployment tomorrow.

Top-level panellists with a diverse background in pavement research, design guidelines and industry applications confirmed that technological responses – and the associated decision support tools – are available to deploy tested and proven solutions with demonstrable benefits in a relatively short time frame.

There is no doubt that knowledge, scientific data and technical guides on improved road materials and construction processes exist in the region and around the world. Decision-makers need to make a bold move on accepting change, promoting innovation, and providing a platform for implementation.

These innovations include high-quality pavement materials with life-extending additives and green pavement technologies such as recycled asphalt materials which combine to offer road agencies a powerful toolkit of energy and environmental performance enhancement mechanisms. As a case in point, modern asphalt rubber mixtures have been tested to deliver improved permanent deformation and fatigue cracking whilst providing a much-needed recycling outlet for end of life tyres.

Panellists also noted that progress is already visible on the ground, but needs to be dramatically scaled up given the magnitude of the problem. In the United Arab Emirates, which hosted the discussions, sustainable pavements and construction practices are well defined and laboratory testing capabilities and modelling techniques are well established. Pavement test sections of modified materials have been installed, and some are being planned for near future installations.

International cooperation and exchange of best practices remain a must, and these questions will continue driving the work of the