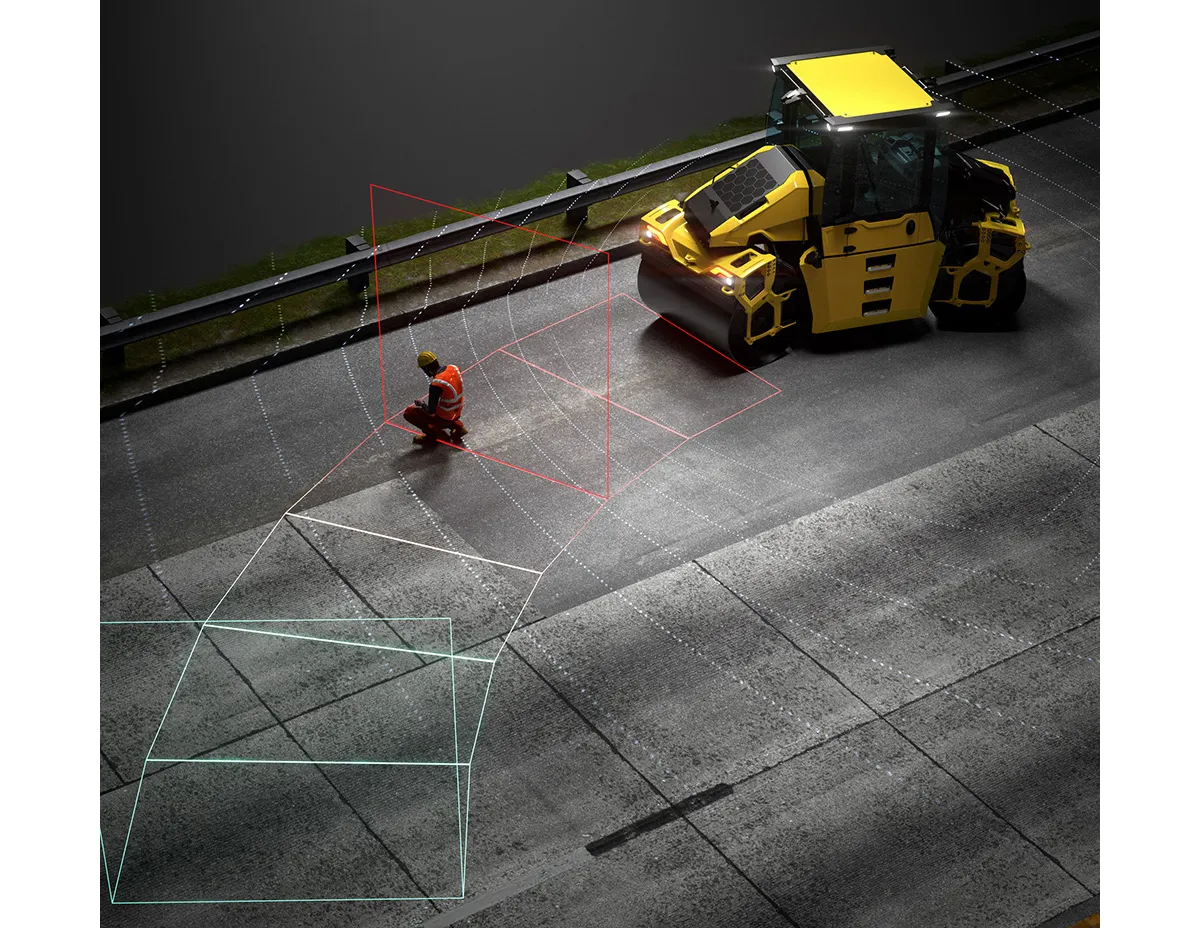

The emergency braking system prevents collisions during operation while protecting the hot asphalt surface from damage. It continuously scans the machine's surroundings, allowing it to recognise potential hazards early and automatically initiate an appropriate driving response.

Lidar-based environment monitoring

Lidar-based environment monitoring

Thanks to the advanced multi-level lidar technology, the machine can accurately assess its surroundings and project its travel path based on speed and steering angle. Other operational parameters are also automatically factored in, such as whether the roller is in crab steering mode. All this enables the reliable detection of people and objects in the machine's path. BOMAG Emergency Brake Assist can identify both stationary and moving obstacles. This allows the localisation of objects and persons that are potentially at risk when the machine is in motion. The fully integrated solution allows the machine to "see around corners", so to speak, and identify obstacles before critical situations arise.

An automated safety system that adapts to the operator

In the event of a potential collision, the emergency brake assistant automatically intervenes, applying different braking strategies. If the driving situation allows, the roller's working speed is only reduced – for example, if a person is already moving out of the vehicle's path and thus away from the potential danger zone. These automatic deceleration features not only help to prevent accidents but also protect the hot asphalt surface from damage caused by abrupt braking. The early anticipation and braking strategies minimise the risk of damage to the asphalt layer and increase the service life of the road surface.

The assist system is displayed and operated via the touchscreen, which is fitted as standard on pivot-steered BOMAG tandem rollers. Emergency Brake Assist can be individually adapted to the driving style of the operator and the specific site conditions. Drivers can adjust the braking intensity in three stages at any time.

The assist system is displayed and operated via the touchscreen, which is fitted as standard on pivot-steered BOMAG tandem rollers. Emergency Brake Assist can be individually adapted to the driving style of the operator and the specific site conditions. Drivers can adjust the braking intensity in three stages at any time.

Optimum support for roller operators

A safe construction site requires the expertise and vigilance of all employees. BOMAG assistance systems are all designed to support them in fulfilling their responsibilities with the best possible technical solutions. The company's Emergency Brake Assist helps to prevent collisions, especially when site conditions are particularly challenging or visibility is poor, for example, at dusk or on night sites. The emergency braking assistant represents a significant advance in safety technology for road construction machinery and offers substantial benefits to both operators and site personnel. It represents an innovative solution that significantly enhances efficiency and safety on construction sites.

More about Emergency Brake Assist:

https://www.bomag.com/ww-en/technologies/overview/emergency-brake-assist/

Content produced in association with Bomag