“This was probably the most complex emulsion plant we have ever produced,” says Massenza commercial director Andrea Menetti. “But it helped that our customer is an expert in emulsion manufacturing and one of the leading companies. We worked very closely with their engineering department to create the design.”

Massenza has worked with the customer, which cannot be named, for over 20 years. Over that time is has supplied a variety of equipment - emulsion plants, cut-back plants, PMB plants, melting units, heaters and storage tanks – to markets around the world including South Africa, Gabon, Ivory Coast, Djibouti, Mauritius and Vietnam.

Massenza, which has an 80-year-plus history in the specialist bitumen plant sector, based the bespoke plant on its MATIC 3500 AA TS emulsion plant which is the biggest and most advanced in the company’s range, producing up to 20tonnes per hour. The plant suctions bitumen directly from local storage and has two water tanks so that the water in the second can be heated while water in the first is used for production.

To meet its client’s requirements, Massenza had to make some major technical changes to the plant. First, there were adaptations to allow frequent switching between anionic and catatonic emulsions. These comprised the addition of two extra lines and pumps for additive dosage and an automated cleaning process which kicks in between the manufacture of the different emulsion types, and which must be completed before the plant will allow the next batch of emulsion to be produced.

Again, with flexibility in mind, this plant allows for two different means of polymer dosing: conventionally in the bitumen or with latex. Since the plant will be used to produce polymer modified bitumen emulsion, which requires higher temperatures, Massenza also developed a new, more efficient cooler which can lower the heat of the emulsion by 40oC – double the normal requirement – in one pass so that it exits at the right temperature. Additionally, a heating system in the lower part of the tank ensures that no residues of cold, hard bitumen build-up.

Again, with flexibility in mind, this plant allows for two different means of polymer dosing: conventionally in the bitumen or with latex. Since the plant will be used to produce polymer modified bitumen emulsion, which requires higher temperatures, Massenza also developed a new, more efficient cooler which can lower the heat of the emulsion by 40oC – double the normal requirement – in one pass so that it exits at the right temperature. Additionally, a heating system in the lower part of the tank ensures that no residues of cold, hard bitumen build-up.

An environmentally driven adaptation was a switch in the heating medium from fossil fuel to electrical power to heat the circulating oil which heats up the emulsion. “This was a system we developed from zero, starting at the end of 2022 and finishing by the end of January 2023,” says Menetti.

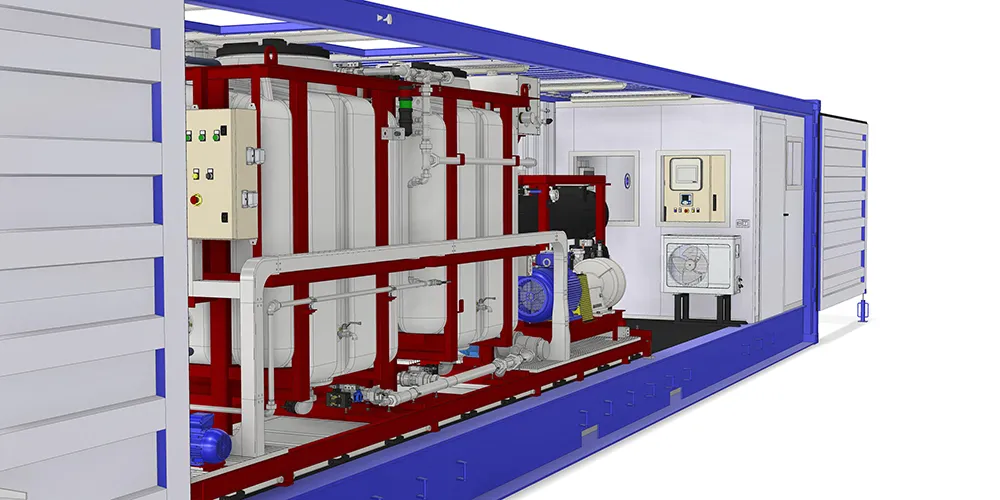

Another challenge for Massenza was how to place the plant inside a container. This isn’t usual practice for Massenza as all its plants are supplied on skids for ease of mobility. However, for this application, security as well as transportability was an issue. “Because it will be located in the middle of the desert, they needed protection from sandstorms – as well as from thieves,” says Menetti.

Major modifications to the container were necessary to allow for ventilation and maintenance access, while still ensuring that the container could be authorised for shipping. Another challenge was that the customer also wanted the control panel to be located in a separate room, rather than close to the plant, and for the room not to be accessed through the plant area.

Given all the bespoke elements for this new plant, Menetti is rightly proud that the process from initial conversations to the plant leaving Massenza’s factory in Fidenza took less than six months. “It was only possible because of the cooperation with our client,” he says. “Together we found the simplest and most reliable solutions.”