The SR-75 in the large diameter piling category brings the power of the SR-80 to the weight class of the SR-65. Weight is around 68 tonnes and power comes in at 328kW, both depending upon configuration of the unit.

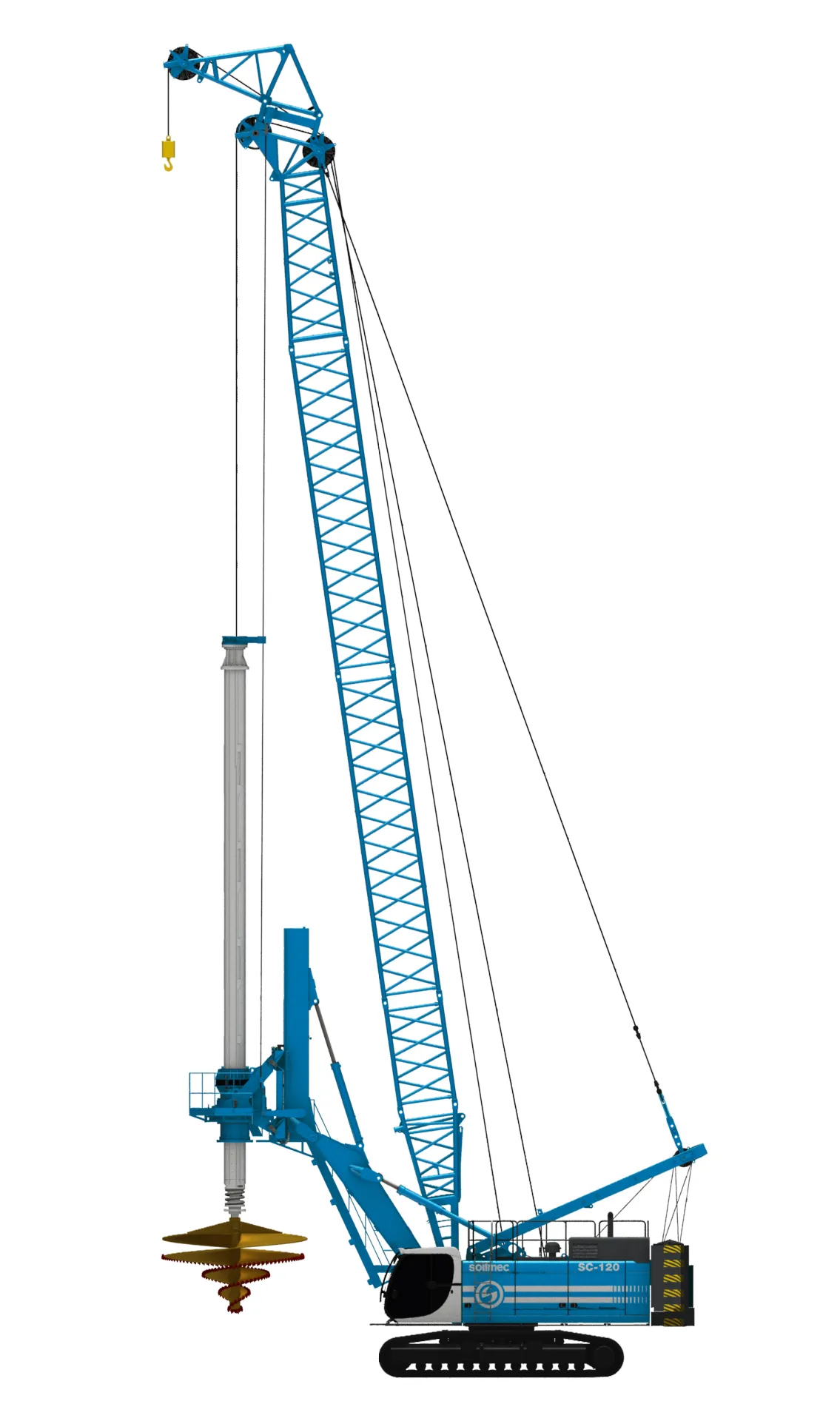

Applications include LDP cased bore piles with casing driven directly by rotary head or optionally by casing oscillator powered by the base carrier itself. Deep uncased bored piles are stabilised by drilling fluid or dry hole.

The unit can complete large diameter bored piles as well as continuous flight auger piles by means of long auger string. There is also the ability for Turbojet soil consolidation and reverse circulation drilling.

The new set-up saves about 10 litres of fuel per hour, according to the company. Improved electrical and hydraulic systems merged with smart positioning of hydraulic components means improved response and smoother performance of all rig operations. Torque on the rotary head is now around 281 kNm of rated value. The DMS 4.0 with a simple navigation menu and intuitive interactive graphics help the operator in day-to-day drilling planning and execution.

Soilmec says that, like all the company’s rigs, the SR-75 is self-assembling, versatile and easily transported. Easy and quick conversion packages lets you create an SR-75 Blue Tech that's a perfect fit for site requirements.