A story that began long ago, back in 1998: the journey of FPT Industrial’s CURSOR engines – one of the best-selling and most renowned series from Iveco Group’s brand dedicated to the design, production, and sale of powertrains and solutions for on- and off-road vehicles, as well as marine and power generation applications – resonates even more strongly this year, as it marks the 50th anniversary of IVECO’s founding.

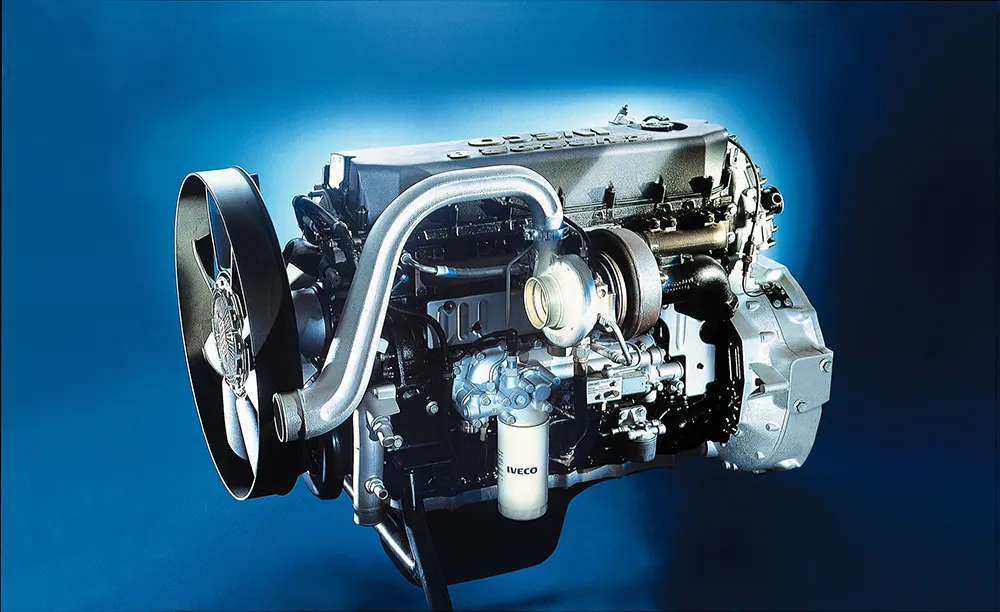

In 1998, indeed, IVECO introduced the CURSOR engine family with the CURSOR 8 and the CURSOR 13, which were later joined by the CURSOR 10 in subsequent years. These engines were the first in the heavy-duty transport sector to feature a variable geometry turbocharger (VGT), optimizing airflow into the engine. The CURSOR series brought a new concept, advanced materials, innovative components, and new electronics, redefining heavy-duty engines through cutting-edge design and engineering choices. In 2004, FPT Industrial introduced the first Natural Gas version of a CURSOR engine, with the CURSOR 8 NG.

In recent years, with the introduction of Euro VI, the CURSOR engine range has continuously evolved to meet customer demands on roads all over the world, ultimately leading to the introduction of the CURSOR 9 and CURSOR 11. These engines have reshaped the approach to on-road challenges, setting new standards of reliability and performance – all while maintaining a strong focus on sustainability.

The CURSOR 9 and the CURSOR 13 were launched in their Natural Gas versions in 2016 and 2017, respectively. Both engines elevated natural gas technology to new heights, further cementing FPT Industrial’s leadership in the natural gas engine sector – a position already validated by significant milestones achieved over the decades.

At the time of its introduction, the CURSOR 9 NG was launched as the most powerful natural gas engine on the market, delivering up to 400 hp at 2,000 rpm and torque of up to 1,700 Nm at 1,200 rpm. These figures were eventually surpassed by the CURSOR 13 NG itself, with a power output of up to 460 hp at 1,900 rpm and torque of up to 2,000 Nm at 1,100 rpm.

Over the years, the CURSOR 13 has been at the forefront of ventures off the beaten path, demonstrating its power and reliability in extreme and boundary-pushing challenges. Among these is the Dakar, the world’s most challenging rally raid. IVECO Powerstar vehicles have been undisputed protagonists of the competition for years, thanks to the extraordinary performance of the CURSOR 13, designed to deliver unmatched power, efficiency, reliability, and sustainability in the toughest conditions. In its customized version for the Dakar, developed to further enhance performance, the CURSOR 13 achieves a maximum rated power of 1,000 hp and a maximum torque of 5,000 Nm. These numbers are backed by results: in the latest edition of the Dakar, IVECO vehicles – powered by FPT Industrial’s engines – swept the podium and secured nine out of the top ten final places in the truck standings.

Today, with a range from 8.7 to 12.9 liters of displacement and covering from 341 to 600 hp, CURSOR engines play a clear role within FPT Industrial’s lineup: delivering top performance to meet heavy-duty challenges on roads worldwide.

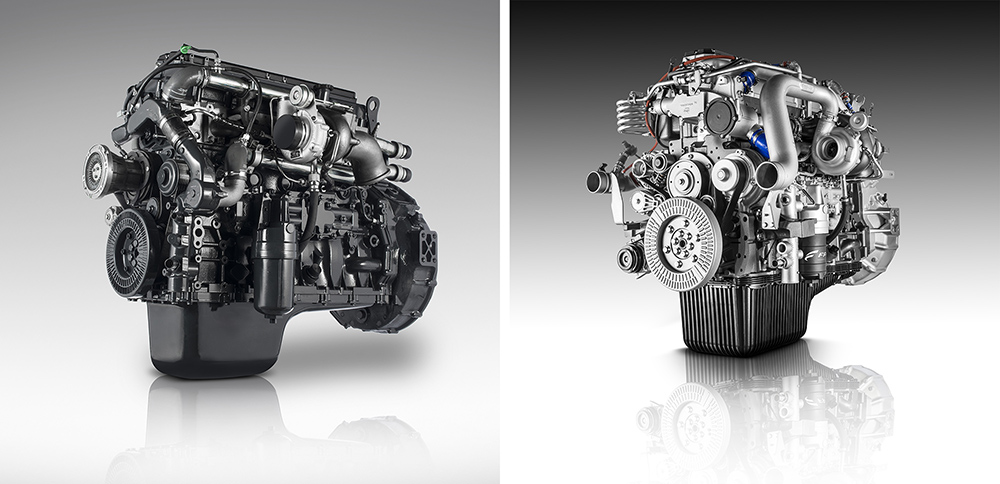

The latest addition to this series is the XCURSOR 13, unveiled in 2022 and entered production in 2024 with the new IVECO Model Year 24. The XCURSOR 13 is FPT Industrial’s first multi-fuel single base engine, designed to run on diesel, methane and, in the future, hydrogen. It is compatible with a wide range of market requirements and easily adaptable for different vehicle installations. For these reasons, it aims to be a primary contributor to achieving CO2 emissions targets and is one of the most relevant parts of FPT Industrial and Iveco Group decarbonization program. The versatility of the XCURSOR 13 has also brought it into the off-road segment: in 2022, the world’s first hydrogen-powered snow groomer with an internal combustion engine, powered by the XCURSOR 13 H2, was introduced.

The XCURSOR 13 fully embodies the role of ICE engines within FPT Industrial's multi-energy strategy, thanks to its concept designed to run on multiple fuels. The diesel version delivers up to 600 hp and 2,850 Nm, offering a 14% increase in torque and 5% more power compared to the previous CURSOR 13. The natural gas version delivers up to 520 hp and 2,500 Nm, with a 25% increase in torque and a 13% boost in power compared to the previous CURSOR 13 NG, taking its world-leading position of most powerful NG engine on the market. The XCURSOR 13 features new air handling for downspeeding and fast transient response along with improved combustion efficiency, with increased Common Rail and peak cylinder pressures. It boasts state-of-the art technologies such as a new smart oil and water pump, advanced combustion control, thermal management, and friction reduction thanks to new connecting rod pins and crankpin materials. The new XCURSOR 13 offers a wide range of ratings for different applications, from 460 hp/2,300 Nm to 600 hp/2,850 Nm. Best-in class performance, alongside CO2 emission reductions of up to 7% for diesel version and up to 8% for Natural Gas version, together with a 10% weight reduction compared to the previous version, are the key expression of the DNA of this engine.

"The new XCURSOR 13 is the result of extensive work” commented Andrea Abbà, On Road Portfolio and Product Manager at FPT Industrial – “which has reimagined the engine across multiple areas and components. It has been completely redesigned, starting with the engine block, which has transitioned from cast iron to compact graphite iron. We have reduced the size of the crankshaft, connecting rods, and pistons, decreasing both weight and friction. A new valve actuation system has been introduced to deliver best-in-class braking power. These are just a few of the innovations in an engine that underscores the continued importance of ICE technology within FPT Industrial’s multi-energy strategy, alongside the development of the ePowertrain lineup."

The XCURSOR 13, in its Diesel and Natural Gas versions, is currently powering IVECO S-Way, T-Way and X-Way and is central to the vehicles’ excellent profitability and sustainability. Recently, the IVECO S-Way Model Year 2024 has received confirmation from TÜV SÜD that it offers a fuel consumption reduction of up to 10.54% compared to its predecessor (Model Year 2022) – a great result driven by the XCURSOR 13.

Over a journey spanning more than 25 years, FPT Industrial's CURSOR engines have played a crucial role in the development of the brand across all markets, setting new standards and establishing themselves as true benchmarks of excellence, embodying the technological research and innovation pursued by the brand. Today, all this heritage is carried forward by the XCURSOR 13, set to bring FPT Industrial’s DNA to roads around the world.

Click here to find out more.

Content produced in association with FPT Industrial