Leading German road marking product manufacturer Evonik Industries has played a key role in improving safety on a popular Colombian tourist highway, as Guy Woodford reports

Bearing the name of the memorable peacemaker governor of Antioquia, the Guillermo Gaviria Correa road, located between the Colombian municipalities of Medellin and San Jerónimo, connects Medellin to the Uraba Gulf part of the Caribbean Sea.

In operation since 2007, the road, in combination with the Fernando Gómez Martínez tunnel –

May 15, 2014

Read time: 3 mins

Leading German road marking product manufacturer Evonik Industries has played a key role in improving safety on a popular Colombian tourist highway, as Guy Woodford reports

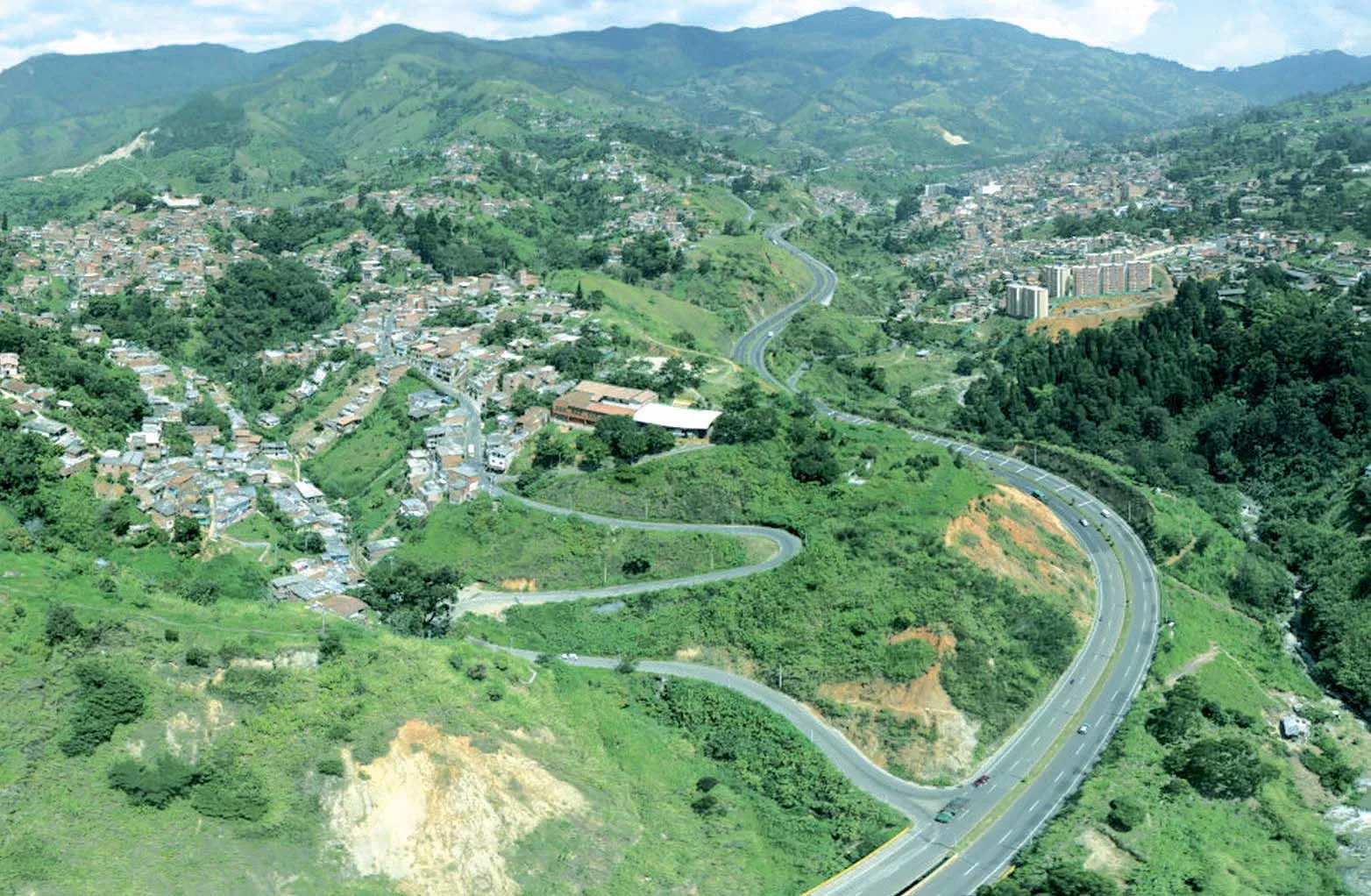

Bearing the name of the memorable peacemaker governor of Antioquia, the Guillermo Gaviria Correa road, located between the Colombian municipalities of Medellin and San Jerónimo, connects Medellin to the Uraba Gulf part of the Caribbean Sea.

In operation since 2007, the road, in combination with the Fernando Gómez Martínez tunnel – the longest tunnel in South America - has improved the mobility in the region by 50% by doing away with the curvy roads once commonplace. Having an average daily traffic of 5,000 vehicles, the road receives more than of 13,000 vehicles on weekends which mostly include travellers seeking relaxation in the tourist areas of Santa Fé de Antioquia, San Jerónimo and Sopetrán.

The Guillermo Gaviria Correa route is composed of a combination of different asphalt types: the main road substrate is bituminous-based flexible asphalt, whereas the toll areas are paved with micro-agglomerate asphalt in order to reduce the early onset of surface rutting in the braking and acceleration areas. Acrylic water-based road markings used to be applied on this road. “The road is marked by some curves which increase the wear of the road marking material and we have a region with high rainfall levels of up to 160mm per month. The water-based road marking system that was traditionally applied was not lasting more than seven months under these conditions,” said the director of operation and maintenance of the Fernando Gómez Martínez tunnel, Jose Fernando Flórez Duque.

In order to provide greater safety to drivers, a road marking that provides higher visibility at night and under rainy conditions combined with an audible warning signal was preferred. “It has been found that 30% of lane departure accidents are caused by inattention or distraction. The scenic journey possibly combined with driver fatigue causes them to drive off the road or cross over the lane. In order to provide an additional road safety tool, we opted for a relatively low cost and sustainable audible warning signal based on MMA cold plastics,” added Duque.

The centre lines were marked with4009 Evonik’s 1659 Degaroute-based MMA cold plastic system in the form of regular dots. The audible alarm warning occurs once the wheel tyres cross the marking and can be adjusted by the height and uniformity of the dot pattern.

The edge lines were marked with Degaroute-based structured marking with an average height of 3.7mm (145mils) for better anti-skid resistance and audible features. MMA cold plastic based on Degaroute was considered to be the most appropriate road marking system.

“We decided to apply a road marking that provides better performance and durability, ensuring longer service life that reduces administrative and operating costs of frequent road work. In addition, we have seen better wet-night visibility since the glass beads of the marking are not covered by rainwater,” said Duque.

“Of course we made test drives on the newly marked route and the first thing that came to our minds was that this is the road marking that talks to drivers! It is amazing and we have heard from road users that the sound emitted by the tyres, once passing over the marking, has led to more careful driving behaviour. Road accidents have considerably decreased since the application of this road marking and this is exactly what we were aiming for,” added Duque.

Bearing the name of the memorable peacemaker governor of Antioquia, the Guillermo Gaviria Correa road, located between the Colombian municipalities of Medellin and San Jerónimo, connects Medellin to the Uraba Gulf part of the Caribbean Sea.

In operation since 2007, the road, in combination with the Fernando Gómez Martínez tunnel – the longest tunnel in South America - has improved the mobility in the region by 50% by doing away with the curvy roads once commonplace. Having an average daily traffic of 5,000 vehicles, the road receives more than of 13,000 vehicles on weekends which mostly include travellers seeking relaxation in the tourist areas of Santa Fé de Antioquia, San Jerónimo and Sopetrán.

The Guillermo Gaviria Correa route is composed of a combination of different asphalt types: the main road substrate is bituminous-based flexible asphalt, whereas the toll areas are paved with micro-agglomerate asphalt in order to reduce the early onset of surface rutting in the braking and acceleration areas. Acrylic water-based road markings used to be applied on this road. “The road is marked by some curves which increase the wear of the road marking material and we have a region with high rainfall levels of up to 160mm per month. The water-based road marking system that was traditionally applied was not lasting more than seven months under these conditions,” said the director of operation and maintenance of the Fernando Gómez Martínez tunnel, Jose Fernando Flórez Duque.

In order to provide greater safety to drivers, a road marking that provides higher visibility at night and under rainy conditions combined with an audible warning signal was preferred. “It has been found that 30% of lane departure accidents are caused by inattention or distraction. The scenic journey possibly combined with driver fatigue causes them to drive off the road or cross over the lane. In order to provide an additional road safety tool, we opted for a relatively low cost and sustainable audible warning signal based on MMA cold plastics,” added Duque.

The centre lines were marked with

The edge lines were marked with Degaroute-based structured marking with an average height of 3.7mm (145mils) for better anti-skid resistance and audible features. MMA cold plastic based on Degaroute was considered to be the most appropriate road marking system.

“We decided to apply a road marking that provides better performance and durability, ensuring longer service life that reduces administrative and operating costs of frequent road work. In addition, we have seen better wet-night visibility since the glass beads of the marking are not covered by rainwater,” said Duque.

“Of course we made test drives on the newly marked route and the first thing that came to our minds was that this is the road marking that talks to drivers! It is amazing and we have heard from road users that the sound emitted by the tyres, once passing over the marking, has led to more careful driving behaviour. Road accidents have considerably decreased since the application of this road marking and this is exactly what we were aiming for,” added Duque.