A number of tower cranes have helped complete the Chishi Grand Bridge project in China

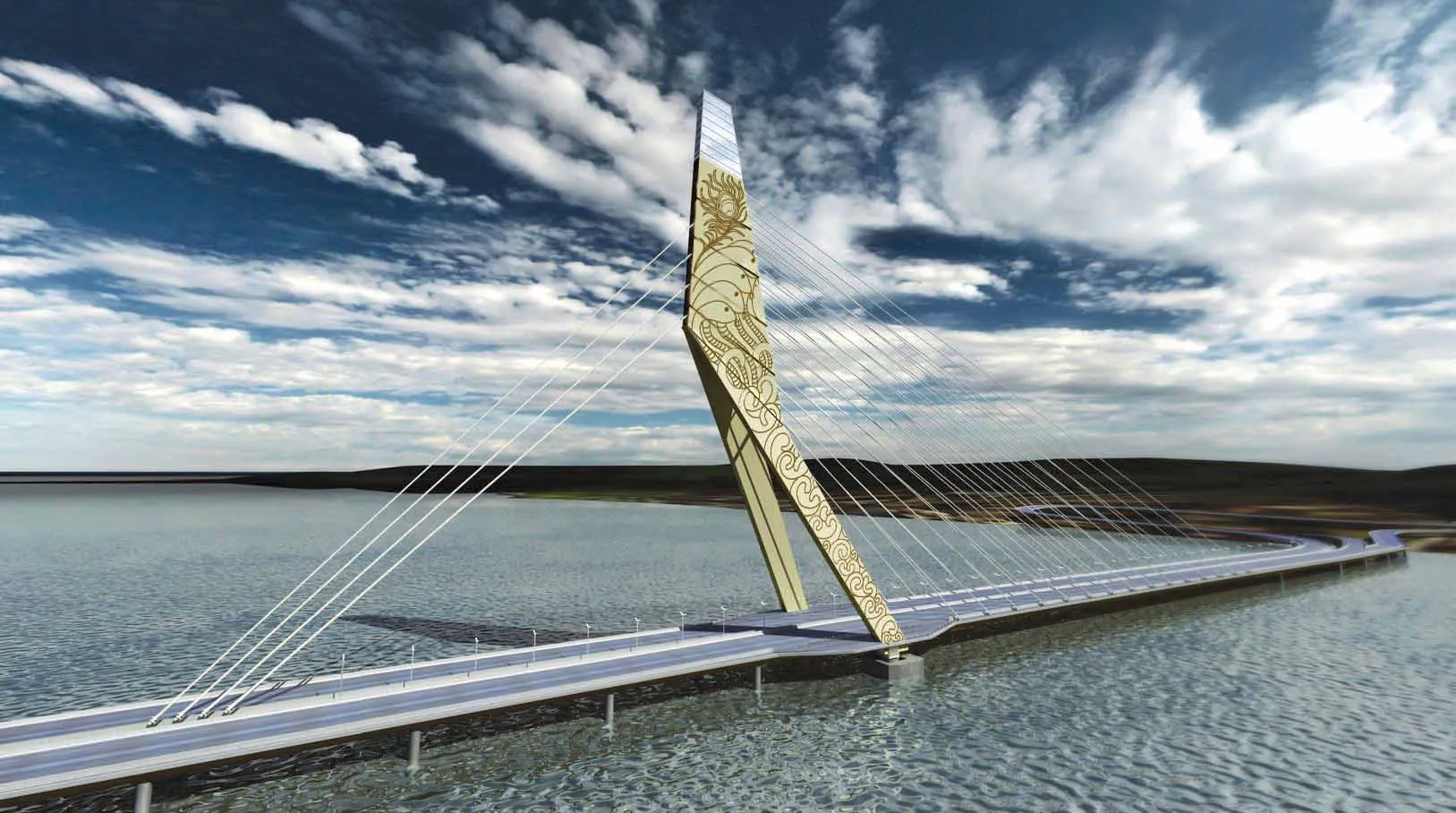

Six Potain tower cranes were used to build two 280m tall bridge pylons, high in the clouds above the mountains of southern China. The cranes spent 30 months building the pylons at the Chishi Grand Bridge, which will span 1.47km and carry its road deck 180m above the ground. The bridge will open at the end of 2014.

The China Railway Major Bridge Engineering Group (CRMBEC) is the main contractor on the project which, at 70m wide, will be one of the widest cable-stayed bridges in the world. The Chishi Grand Bridge forms part of the Xiarong Expressway, which connects Rucheng to Chenzhou in the south-east of Hunan province. CRMBEC owns and operates the Potain tower cranes used on the project.

Standing up to 310m tall, the six Potain tower cranes coped well with Hunan’s subtropical climate at the Chishi Grand Bridge project. Monsoon rain and extreme humidity were among the challenges at the job site. Communication between ground crews and operators was also important as the cranes were often hidden in the clouds, with no view of the ground below.

The Potain cranes built two of the bridge’s four pylons, each of which has 24 exterior sides and 36 interior sides, forming a novel S-shape structure. This technical arrangement made construction all the more complicated.

To ensure the cranes operated at maximum efficiency for the long hours required at the project, Manitowoc Crane Care worked closely with the site. At one stage, the customer support division even needed to deliver some components and parts to the job site by helicopter, to ensure the project stayed on schedule.

The cranes lifted a wide variety of construction materials, including formwork and steel structures, in loads that tested their maximum capacities, which ranged up to 16tonnes. Work began on the Chishi Grand Bridge in March 2010. The Potain tower cranes were erected at the job site in March 2011 and more recently finished work. The cranes on site included two MC 200s and two cranes that mix the mast of an MC 480 with the jib of an MC 320 K16. All of the cranes were built at Potain’s factory in Zhangjiagang, China. CRMBEC is a wholly-owned subsidiary of China Railway Group Ltd and specialises in bridge construction, completing some of the largest in the world to date.

Cranes help construct major bridge project in CHina

A number of tower cranes have helped complete the Chishi Grand Bridge project in China Six Potain tower cranes were used to build two 280m tall bridge pylons, high in the clouds above the mountains of southern China. The cranes spent 30 months building the pylons at the Chishi Grand Bridge, which will span 1.47km and carry its road deck 180m above the ground. The bridge will open at the end of 2014.

September 8, 2014

Read time: 3 mins