Commuter traffic in the Taipei Metropolitan Area is a major concern for the city’s town planners. In 2009, a decision was reached to widen National Freeway No. 1 between Wugu and Yangmei on a 42km section of freeway on the northern part of town. The lane-widening project saw the construction of two new viaducts built along each side of the freeway.

From the onset, the project presented tremendous challenges owing to various factors, including limited space for construction; passing through a geologically

September 15, 2015

Read time: 3 mins

National Freeway No 1 Widening Project

Commuter traffic in the Taipei Metropolitan Area is a major concern for the city’s town planners. In 2009, a decision was reached to widen National Freeway No. 1 between Wugu and Yangmei on a 42km section of freeway on the northern part of town. The lane-widening project saw the construction of two new viaducts built along each side of the freeway.

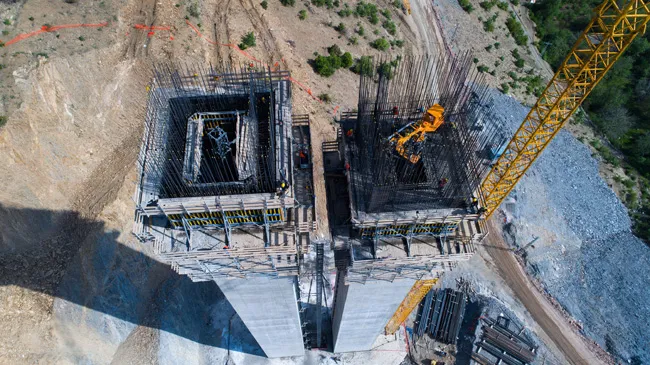

From the onset, the project presented tremendous challenges owing to various factors, including limited space for construction; passing through a geologically sensitive area; maintaining traffic on a busy section of freeway with 250,000 vehicles per day; and implementing a complex technical design. New and innovative construction methods were introduced by project designer CECI Engineering Consultants, Inc (CECI) aimed at fast-tracking the project’s design and construction activities by optimising the allocation of construction resources and schedules during all stages of work.

CECI was commissioned to carry out design and construction supervision services for both the northern and middle segments of the project with a continuous running length of 28km, and from the start, undertook a design emphasising speed, value and innovation without sacrificing quality and safety.

Notable features of the project included pioneering construction processes, as illustrated by the utilisation of a new horizontal rotation method aimed at shortening construction time and avoiding deploying piers or supporting structures that would otherwise have disrupted existing traffic. To avoid impeding the traffic flow, overpasses were designed for the viaduct to cross the freeway and merge into a double-deck structure.

Throughout the project environmentally protective measures were adopted ranging from tree relocation and transplantation, to the designation of non-disturbance zones aimed at preserving the habitats, ground soil and wetlands. Noise reduction measures, such as low noise expansion joints and infiltration pavement, were also adopted to maximise performance of the viaduct. Finally, an “F type” double-deck structure merging the two viaducts along both sides of the freeway together allowing both decks to use the same supporting columns was selected in order to avoid a geologically sensitive area.

After four years of intensive efforts, the entire viaduct was opened to traffic in April 2013 at a total cost of US $2.02 billion, significantly below an earlier estimate of US $2.94 billion.

Since completion, the “Wu-Yang Viaduct” has been highly praised for its immediate impact and success in restoring smooth and fast flowing traffic to this section of National Freeway No 1. Measurable benefits have included shortening the travel time along the section by increasing the peak-hour vehicular speed from 40-90km/h, mitigating an estimates 32,500tonnes of carbon emissions/ year and saving fuel costs of US $1.7 million/ year.

The project is also a testament of how the collective efforts of the government, designers and builders can realise an innovative road engineering design solution, which answers to the needs of society and while helping conserve the environment.

Commuter traffic in the Taipei Metropolitan Area is a major concern for the city’s town planners. In 2009, a decision was reached to widen National Freeway No. 1 between Wugu and Yangmei on a 42km section of freeway on the northern part of town. The lane-widening project saw the construction of two new viaducts built along each side of the freeway.

From the onset, the project presented tremendous challenges owing to various factors, including limited space for construction; passing through a geologically sensitive area; maintaining traffic on a busy section of freeway with 250,000 vehicles per day; and implementing a complex technical design. New and innovative construction methods were introduced by project designer CECI Engineering Consultants, Inc (CECI) aimed at fast-tracking the project’s design and construction activities by optimising the allocation of construction resources and schedules during all stages of work.

CECI was commissioned to carry out design and construction supervision services for both the northern and middle segments of the project with a continuous running length of 28km, and from the start, undertook a design emphasising speed, value and innovation without sacrificing quality and safety.

Notable features of the project included pioneering construction processes, as illustrated by the utilisation of a new horizontal rotation method aimed at shortening construction time and avoiding deploying piers or supporting structures that would otherwise have disrupted existing traffic. To avoid impeding the traffic flow, overpasses were designed for the viaduct to cross the freeway and merge into a double-deck structure.

Throughout the project environmentally protective measures were adopted ranging from tree relocation and transplantation, to the designation of non-disturbance zones aimed at preserving the habitats, ground soil and wetlands. Noise reduction measures, such as low noise expansion joints and infiltration pavement, were also adopted to maximise performance of the viaduct. Finally, an “F type” double-deck structure merging the two viaducts along both sides of the freeway together allowing both decks to use the same supporting columns was selected in order to avoid a geologically sensitive area.

After four years of intensive efforts, the entire viaduct was opened to traffic in April 2013 at a total cost of US $2.02 billion, significantly below an earlier estimate of US $2.94 billion.

Since completion, the “Wu-Yang Viaduct” has been highly praised for its immediate impact and success in restoring smooth and fast flowing traffic to this section of National Freeway No 1. Measurable benefits have included shortening the travel time along the section by increasing the peak-hour vehicular speed from 40-90km/h, mitigating an estimates 32,500tonnes of carbon emissions/ year and saving fuel costs of US $1.7 million/ year.

The project is also a testament of how the collective efforts of the government, designers and builders can realise an innovative road engineering design solution, which answers to the needs of society and while helping conserve the environment.