German contractor Autobahnamt Montabaur is maintaining highways and roadside woodland – all with the support of Volvo CE’s redesigned EW160E wheeled excavator.

The Volvo EW160E wheeled excavator’s compact design is perfect for confined highway construction job sites. Stretched across the heart of central Germany lies a network of often tree-lined highways. Nestled among the woodland and amidst the Rhenish Massif mountain range, is Westerwald, meaning ‘Western Forest.’ The city’s 13,000 inhabitants and 4

January 4, 2016

Read time: 3 mins

German contractor Autobahnamt Montabaur is maintaining highways and roadside woodland – all with the support of 359 Volvo CE’s redesigned EW160E wheeled excavator.

The Volvo EW160E wheeled excavator’s compact design is perfect for confined highway construction job sites. Stretched across the heart of central Germany lies a network of often tree-lined highways. Nestled among the woodland and amidst the Rhenish Massif mountain range, is Westerwald, meaning ‘Western Forest.’ The city’s 13,000 inhabitants and 40,000 district residents rely on the highway for economic growth and so must be maintained to the highest standard.

The authority – Mobility Rheinland-Pfalz (LBM) – designs, builds and maintains the 18,000km of highways, federal state and county roads in Rheinland-Palatinate. Of this total route network, 877km are being maintained by Autobahnamt Montabaur. With over 700 employees, the company’s duties include tree-cutting and salt dispersion to pavement rehabilitation and warning sign placement.

However, during the tree-cutting months from October to March, Autobahnamt Montabaur is primarily tasked with wood maintenance along the tree-lined highways.

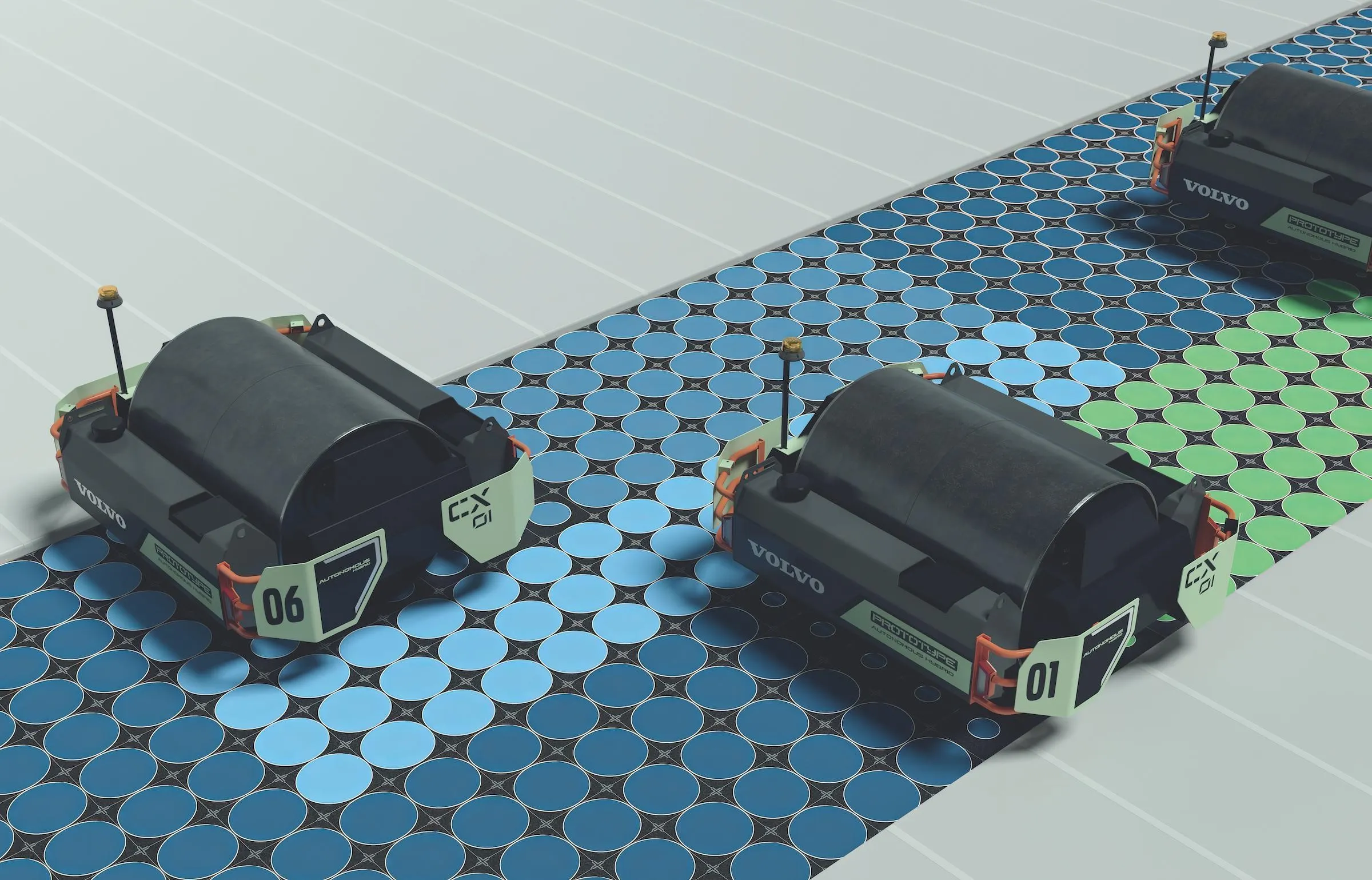

To complete tree-cutting projects in a timely and efficient manner, Autobahnamt Montabaur uses the Volvo Construction Equipment (Volvo CE) EW160E wheeled excavator. Formerly rented solely for the tree-cutting months, Autobahnamt Montabaur recently added the wheeled excavator to their permanent fleet, joining the 11 Volvo L35G compact wheel loaders the company also operates.

As arguably the most advanced multitool carrier in the industry, the wheeled excavator is ideal for jobs that require flexibility, independence of movement and operational safety. To further aid productivity and reduce fuel consumption, the machine is powered by the robust Volvo Tier 4f engine that features automatic idling as standard, which not only cuts fuel use but noise pollution too.

When in timber management configuration Autobahnamt Montabaur uses a HABBIG HS850 Schnitt-Griffy hydraulic hedge shear and extraction gripper – allowing the operator to secure, cut and remove branches and trees quickly, accurately and safely.

To enhance the safety of operations, Autobahnamt Montabaur has added the optional Volvo Smart View system to its new EW160E. The system uses cameras attached to the front-right, front-left and rear of the wheeled excavator which provide a bird’s-eye view of the machine operating from above.

The 360 degree view of actual footage happening in real time allows the operator to see his surroundings and ensure safe rotation.

The Volvo EW160E wheeled excavator’s compact design is perfect for confined highway construction job sites. Stretched across the heart of central Germany lies a network of often tree-lined highways. Nestled among the woodland and amidst the Rhenish Massif mountain range, is Westerwald, meaning ‘Western Forest.’ The city’s 13,000 inhabitants and 40,000 district residents rely on the highway for economic growth and so must be maintained to the highest standard.

The authority – Mobility Rheinland-Pfalz (LBM) – designs, builds and maintains the 18,000km of highways, federal state and county roads in Rheinland-Palatinate. Of this total route network, 877km are being maintained by Autobahnamt Montabaur. With over 700 employees, the company’s duties include tree-cutting and salt dispersion to pavement rehabilitation and warning sign placement.

However, during the tree-cutting months from October to March, Autobahnamt Montabaur is primarily tasked with wood maintenance along the tree-lined highways.

To complete tree-cutting projects in a timely and efficient manner, Autobahnamt Montabaur uses the Volvo Construction Equipment (Volvo CE) EW160E wheeled excavator. Formerly rented solely for the tree-cutting months, Autobahnamt Montabaur recently added the wheeled excavator to their permanent fleet, joining the 11 Volvo L35G compact wheel loaders the company also operates.

As arguably the most advanced multitool carrier in the industry, the wheeled excavator is ideal for jobs that require flexibility, independence of movement and operational safety. To further aid productivity and reduce fuel consumption, the machine is powered by the robust Volvo Tier 4f engine that features automatic idling as standard, which not only cuts fuel use but noise pollution too.

When in timber management configuration Autobahnamt Montabaur uses a HABBIG HS850 Schnitt-Griffy hydraulic hedge shear and extraction gripper – allowing the operator to secure, cut and remove branches and trees quickly, accurately and safely.

To enhance the safety of operations, Autobahnamt Montabaur has added the optional Volvo Smart View system to its new EW160E. The system uses cameras attached to the front-right, front-left and rear of the wheeled excavator which provide a bird’s-eye view of the machine operating from above.

The 360 degree view of actual footage happening in real time allows the operator to see his surroundings and ensure safe rotation.