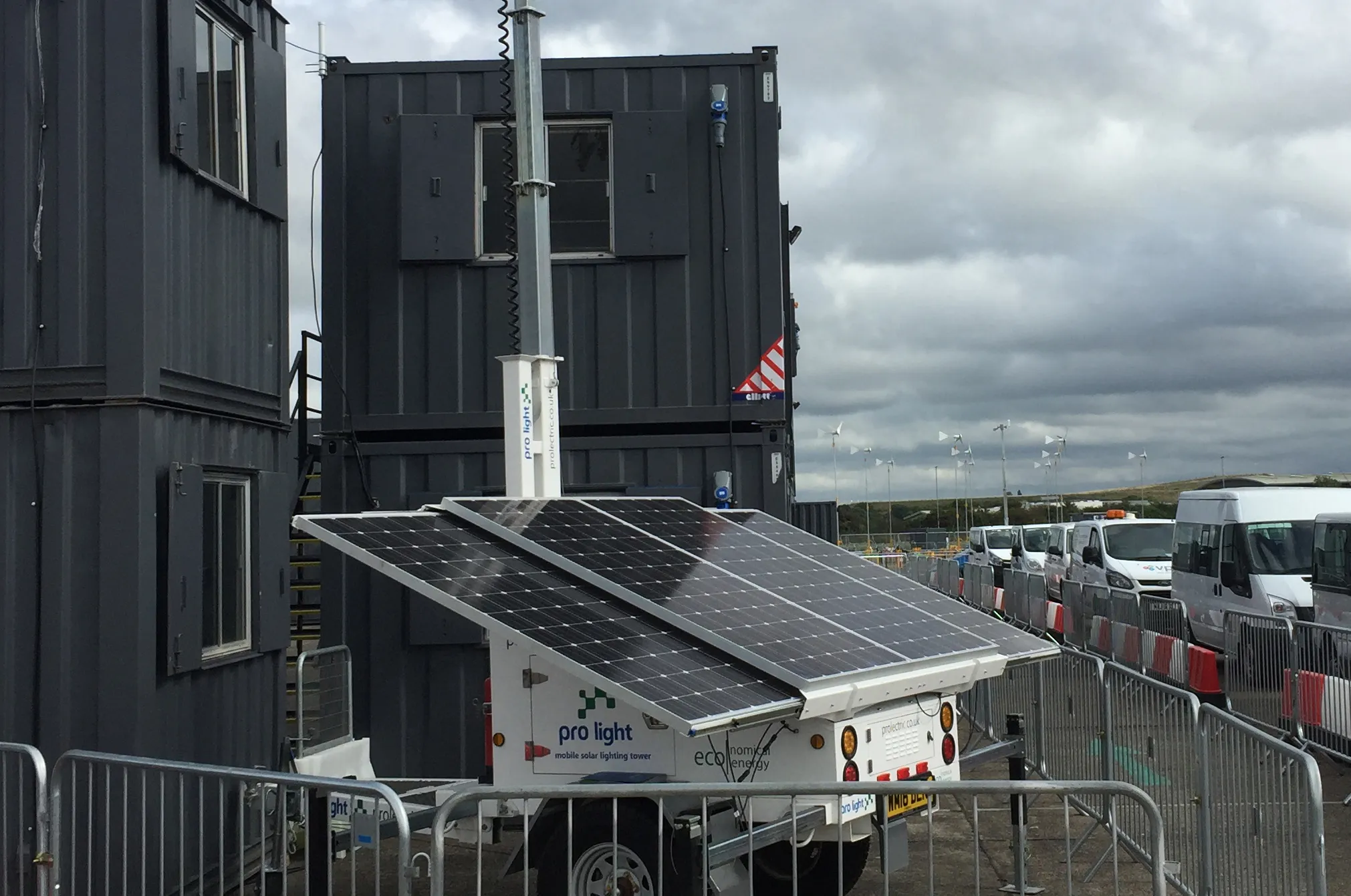

The mobile solar-powered lighting is said to offer cost savings for highways contractors and trials of the Prolectric ProLight have demonstrated its carbon and air quality benefits as an alternative to temporary diesel lighting towers. The technology has been pioneered by Prolectric to deliver year-round solar lighting and optimise winter performance. Temporary lighting frequently has to be deployed in heavily-populated urban areas and worker compounds for motorway and transport projects.

According to the firm, its solar lighting systems offer major cost benefits in comparison to diesel-powered units, by eliminating the need for refuelling and engine servicing. The company says that its solar array offers three times the power of any other solar light previously available. The firm says that it also built in smart technology so that the unit’s on and off times could be controlled automatically while data on power usage and carbon savings could be monitored remotely.

Every ProLight is fitted with a micro-controller and GPS tracking, so it can monitored to ensure continued operation, enable on/off times to be adjusted remotely, as well as to record key data such as power generated and consumed.