Atlas Copco is now offering an updated version of its proven QAS 60 generator that is designed to provide greater mobility. A smaller footprint allows for 12 QAS 60 generators to be fitted into a standard container.

The firm has made the design more compact as this helps cut transportation costs for its customers, especially those in the rental business. The new QAS 60 is less than 2.4m long so it can be placed sideways on a truck. This allows more units to be carried on a truck and also ensures easier

December 8, 2014

Read time: 2 mins

The firm has made the design more compact as this helps cut transportation costs for its customers, especially those in the rental business. The new QAS 60 is less than 2.4m long so it can be placed sideways on a truck. This allows more units to be carried on a truck and also ensures easier loading and unloading.

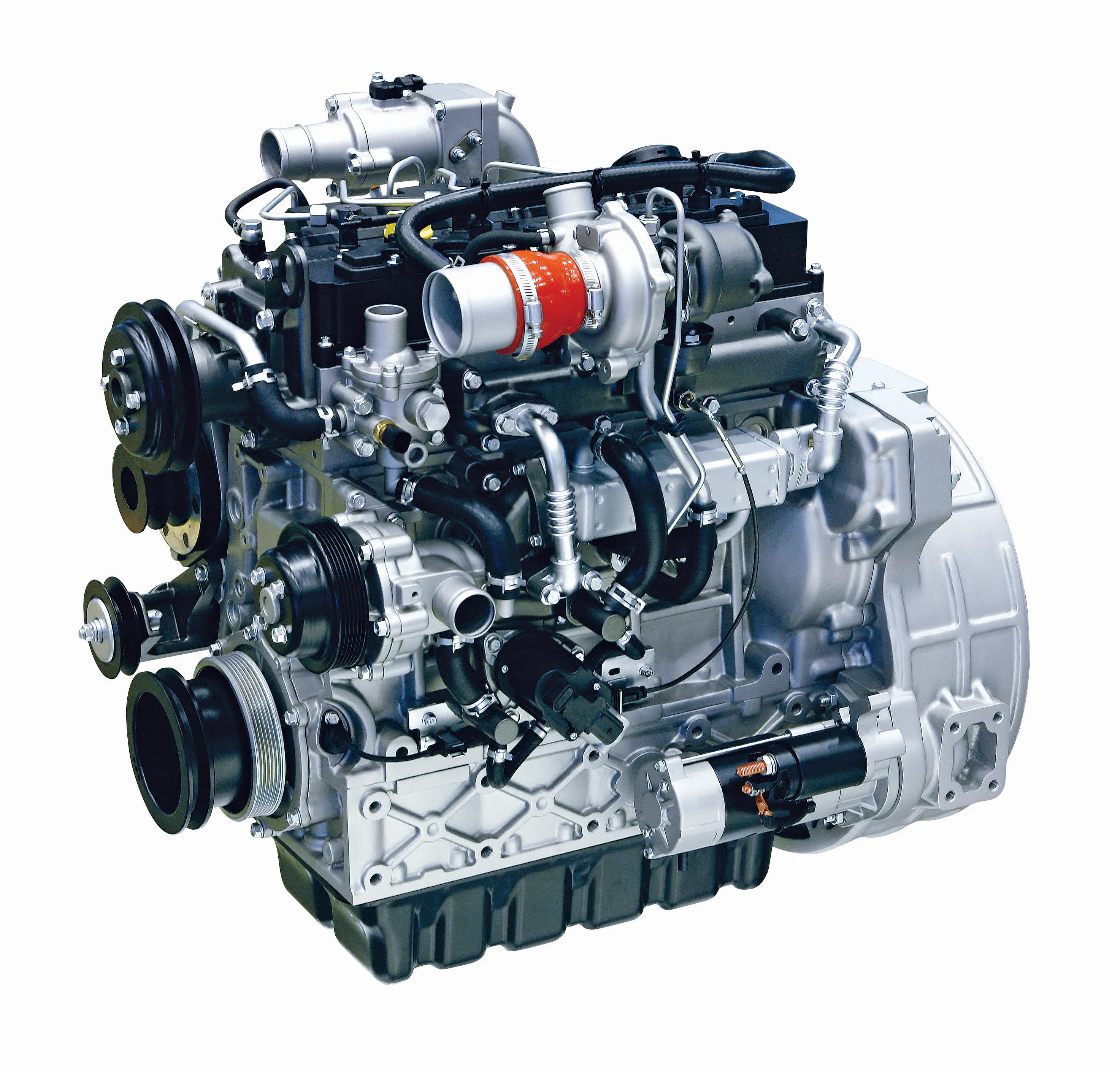

The new QAS 60 delivers the same output and performance as the previous model, retaining the proven