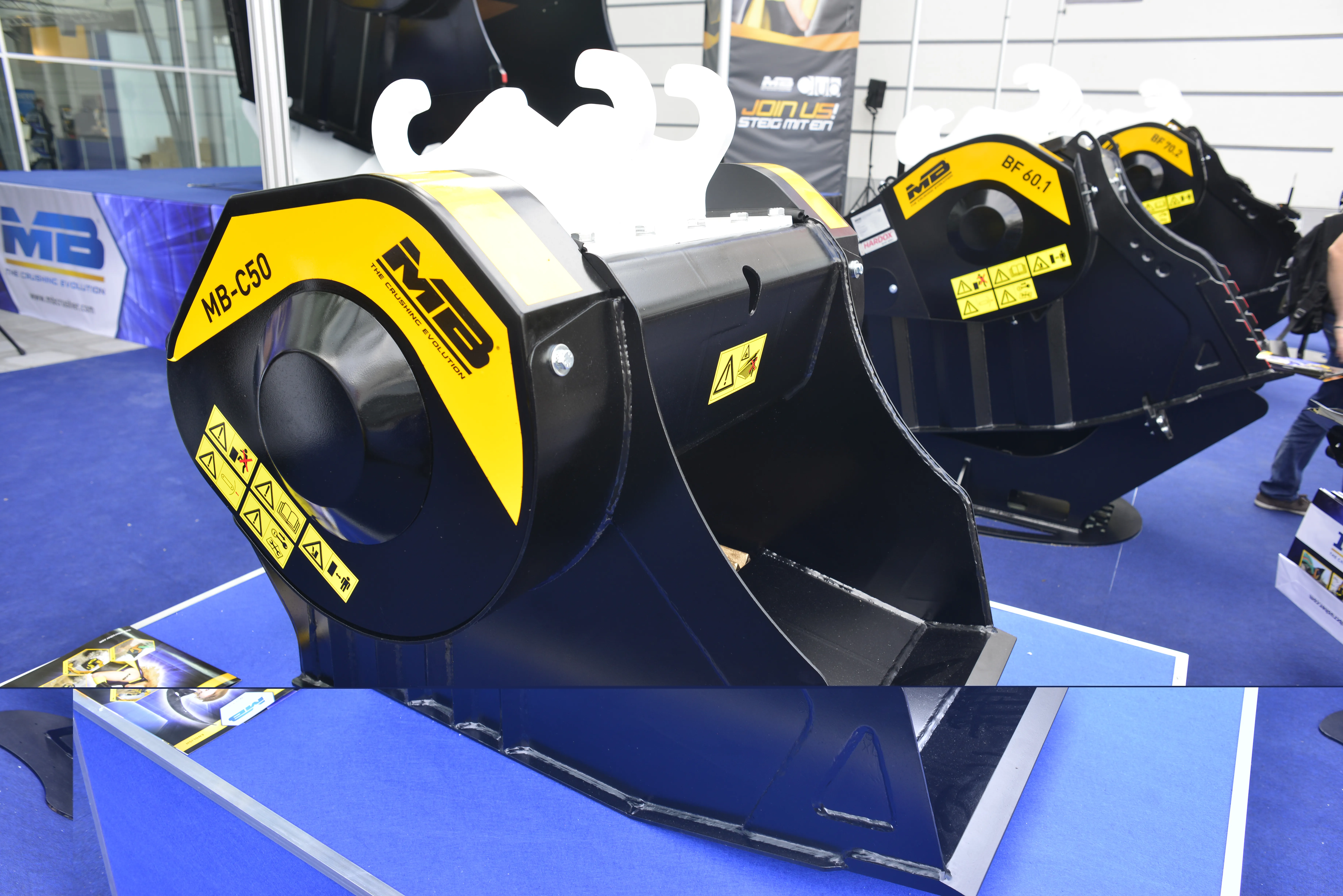

Crushing buckets from

On the island of Rab in Croatia, a unit from MB Crusher has been used to produce road materials for access roads to house construction sites. The crusher bucket was utilised for the task as quarried material would have proven too costly. Instead, the developer opted to use rubble cleared from the site. One of the compact MB-L200 units from the MB Crusher range was fitted to a backhoe loader and used to crush the waste rock from the site clearance operations. This provided crushed rock of a suitable size and quality to be used as road bed material for the access roads to the construction site. With the crushing bucket, the developer was able to produce the material onsite, reducing transport costs in comparison with sourcing material from a quarry elsewhere. In addition, the developer mounted the crushing bucket on an existing piece of site equipment, further lowering costs.

Similarly on the Mayotte Islands, part of the Comoros archipelago in the Indian Ocean, equipment from MB Crusher proved valuable for producing material. On the island, access to the basalt rock quarries used to produce road materials is restricted. However, road building activities have been assisted by the use of BF135.8 unit from MB Crusher. This 1.6m3 capacity unit is more compact than conventional crushing plant, allowing it to be brought to the quarry site more easily. The quarry is now producing aggregate at a rate of 88m3/hour for local road building work.

And on the islands of Saint-Pierre and Miquelon, two mountainous islands in the Atlantic Ocean, to the South of Newfoundland in Canada, units from MB Crusher are helping with road building activities. In order to build a number of road links it was necessary to make a cutting through a mountain. Restricted space onsite and high transport costs meant that the MB Crusher unit offered advantages. This proved more cost effective than transporting materials from the site for processing. A contractor used an MB-S18 unit to process granite from the extraction heap onsite. The unit has been able to separate soil from the granite, with the latter then being used for road bed material. The unit has been mounted on a