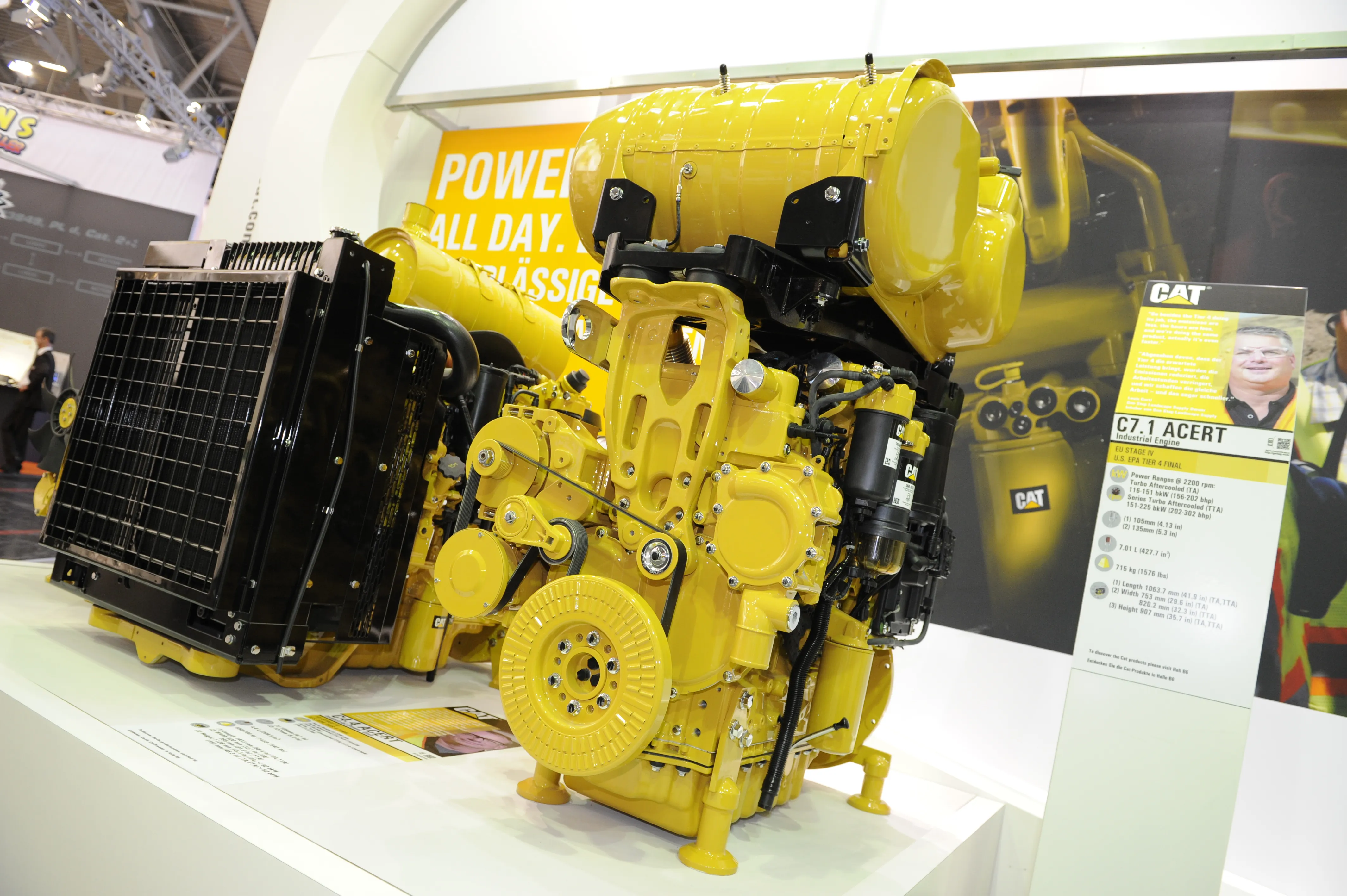

One of the USA’s largest and best-known dealers for Caterpillar off-road vehicles, Whayne Supply, has teamed up with a small UK engineering company, Magnom, to introduce magnetic filtration units that have been shown to increase operational efficiency and decrease downtime.

February 21, 2012

Read time: 2 mins

One of the USA’s largest and best-known dealers for 178 Caterpillar off-road vehicles, 1467 Whayne Supply, has teamed up with a small UK engineering company, 1468 Magnom, to introduce magnetic filtration units that have been shown to increase operational efficiency and decrease downtime.

The filtration units, which remove ferrous particles, are being used in conjunction with traditional barrier techniques to provide “unmatched levels of filtration on the vehicles.”

The custom-designed units, using patented Magnom technology, are now in volume production.

Magnom engineers, led by the company’s technology director and original inventor Jobey Marlowe, worked with Whayne Supply over a three-year period to develop the custom units for the Caterpillar vehicles.

Whayne Supply focuses on the Kentucky and southern Indiana markets and is marketing the new filters to other North American Caterpillar dealers.

The company’s technology division general manager Edwin Downer said: “During testing, we were convinced by the results that adding Magnom units to the machine systems would reduce both operating expenses and unscheduled downtime.”

Magnom chairman Robert Spender said: “It is especially pleasing to us to be working with a partner that has the resources to introduce the benefits of Magnom technology to a wider audience. These benefits quickly translate into reduced warranty and general maintenance costs and so we are quietly confident of take up across North America.”

Magnom units are said to have an exceptionally long life and a design which enables them to capture a surprisingly large mass of ferrous material, filtering particle sizes down to 0.07µ (1µ or micron is equal to one millionth of a metre), while never impeding fluid flow.

The filtration units, which remove ferrous particles, are being used in conjunction with traditional barrier techniques to provide “unmatched levels of filtration on the vehicles.”

The custom-designed units, using patented Magnom technology, are now in volume production.

Magnom engineers, led by the company’s technology director and original inventor Jobey Marlowe, worked with Whayne Supply over a three-year period to develop the custom units for the Caterpillar vehicles.

Whayne Supply focuses on the Kentucky and southern Indiana markets and is marketing the new filters to other North American Caterpillar dealers.

The company’s technology division general manager Edwin Downer said: “During testing, we were convinced by the results that adding Magnom units to the machine systems would reduce both operating expenses and unscheduled downtime.”

Magnom chairman Robert Spender said: “It is especially pleasing to us to be working with a partner that has the resources to introduce the benefits of Magnom technology to a wider audience. These benefits quickly translate into reduced warranty and general maintenance costs and so we are quietly confident of take up across North America.”

Magnom units are said to have an exceptionally long life and a design which enables them to capture a surprisingly large mass of ferrous material, filtering particle sizes down to 0.07µ (1µ or micron is equal to one millionth of a metre), while never impeding fluid flow.