Komatsu Europe has invested in developing an efficient spare parts operation - Mike Woof writes. Komatsu Europe is reaping the benefit of its investments in the spares support facility in Belgium. During the financial crisis new machine sales plummeted across Europe for all manufacturers but Komatsu Europe was able to ensure steady income through its spares support service. With many European customers holding onto machines longer during the last few years due to the downturn, spares support has been pivota

February 29, 2012

Read time: 4 mins

Komatsu Europe has invested in developing an efficient spare parts operation - Mike Woof writes

With many European customers holding onto machines longer during the last few years due to the downturn, spares support has been pivotal for Komatsu Europe. Marketing manager Marc Blondeel said, "During the crisis we did not lay off any warehouse staff." Located close to Belgian capital Brussels, the spares operation is also situated conveniently for the major port of Antwerp. The improved spares facility covers an area of 47,000m2 in all and employs 205 people, working Monday-Friday as well as Saturday mornings. To supply emergency support for customers in the extraction industries where downtime can have major cost implications, the operation can open on Sundays as well if required.

A new storage area is now in use, taking over from a warehouse next to the site that had been rented from another firm. The new parts storage facility was erected immediately alongside the existing building and the two share a common wall with several entrances, although Komatsu opted to retain this wall for safety and security purposes. The new spare parts building contains a large automated

Lubricants are supplied as part of the offering to Komatsu's specification by a leading oil company and include special additives to improve viscosity, increase life and reduce wear. The lubricants required for the Tier 4 Interim/Stage IIIB machines have still more specific performance requirements according to Blondeel.

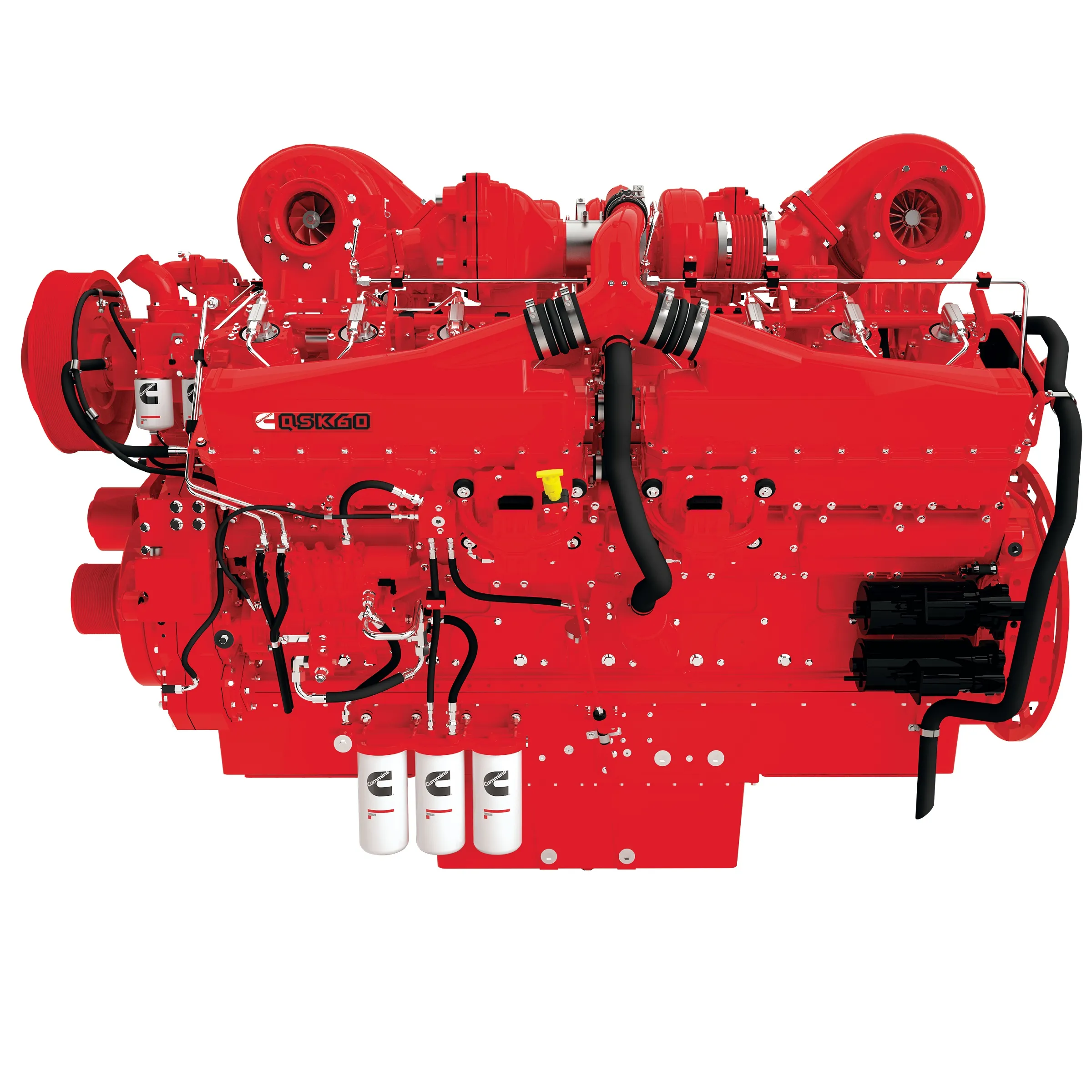

Extra racking has also been set up in the warehouse to provide space for the machines with Tier 4 Interim/Stage IIIB engines.

Hoses are supplied locally from a firm situated opposite the facility and Blondeel said that this ensures the components will have the longest possible life. Manufactured to order to Komatsu's specifications, the hoses will not have age-related problems when they reach the customer. In the past hoses were supplied from Japan and these could be in storage for some time before being supplied to a customer. "We can deliver good quality hoses the next day and our sales are increasing," Blondeel said.

As the maintenance schedules are all available on the KOMTRAX system fitted to all Komatsu's new machines, the dealer can check when service intervals are due and can send the necessary kits to the customer. Using the KOMTRAX system Komatsu Europe can monitor the hours clocked by a machine, performance parameters and wear issues, assessing parts requirements as well as the need for regular service intervals and when the machines need a service. Because the system highlights what is required, this has allowed Komatsu Europe to lower its stock holding and take still more cost out of the supply chain according to Blondeel.

Training is in hand to capitalise on the benefits of the KOMTRAX technology and provide additional long term planning capabilities.

Blondeel said that this will yield still more cost efficiencies in the future.

The combination of the sophisticated KOMTRAX system fitted to the new machines and the new storage facility has allowed Komatsu Europe to streamline the efficiency of its spare parts supply.

This has trimmed operating costs and cut supply times, benefits that are passed on to the customer.

Blondeel said that this improved efficiency is resulting in increased turnover and claimed that the improved operation means that Komatsu Europe has a significant advantage over its closest rivals.